Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 48 CONTINENTAL L-HEAD ENGINE MANUAL<br />

Figure 103 reChecking flywheel timing with<br />

timing light<br />

An alternative method without timing light, is<br />

as follows :<br />

1. Remove ¢~1 Spark Plug -- put your thumb<br />

over the spark plug hole and crank engine by<br />

hand until air is exhausting.<br />

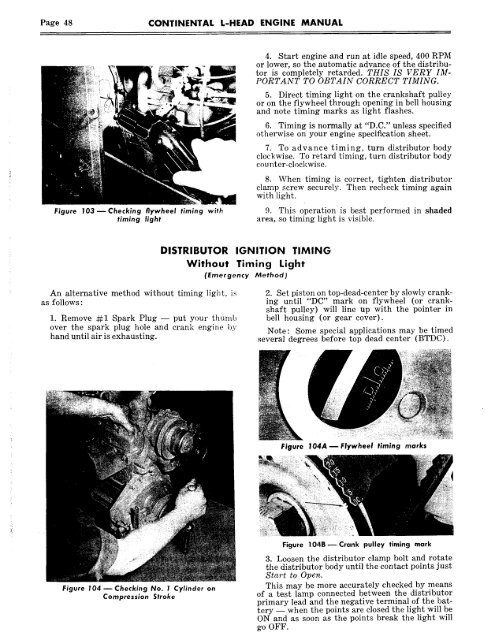

Figure 104 D Checking No. I Cylinder on<br />

Compression Stroke<br />

DISTRIBUTOR IGNITION TIMING<br />

Without Timing Light<br />

(Emergency Method)<br />

4. Start engine and run at idle speed, 400 RPM<br />

or lower, so the automatic advance of the distributor<br />

is completely retarded. THIS IS VERY IM-<br />

PORTANT TO OBTAIN CORRECT TIMING.<br />

5. Direct timing light on the crankshaft pulley<br />

or on the flywheel through opening in bell housing<br />

and note timing marks as light flashes.<br />

6. Timing is normally at "D.C." unless specified<br />

otherwise on your engine specification sheet.<br />

7. To advance timing, turn distributor body<br />

clockwise. To retard timing, turn distributor body<br />

cou nter-clockwise.<br />

8. When timing is correct, tighten distributor<br />

clamp screw securely. Then recheck timing again<br />

with light.<br />

9. This operation is best performed in shaded<br />

area, so timing light is visible.<br />

2. Set piston on top-dead-center by slowly cranking<br />

until "DC" mark on flywheel (or crank~<br />

shaft pulley) will line up with the pointer in<br />

bell housing (or gear cover).<br />

Note: Some special applications may be timed<br />

several degrees before top dead center (BTDC).<br />

Figure I04A ~ Flywheel timing marks<br />

Figure 104BDCrank pulley timing mark<br />

3. Loosen the distributor clamp bolt and rotate<br />

the distributor body until the contact points just<br />

Start to Open.<br />

This may be more accurately checked by means<br />

of a test lamp connected between the distributor<br />

primary lead and the negative terminal of the battery<br />

-- when the points are closed the light will be<br />

ON and as soon as the points break the light will<br />

go OFF.