Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2. The 3 piece oil ring should be installed first<br />

on the piston, from the top side so skirt will not<br />

be scratched.<br />

Figure |37--Install Tapered Rings with "Top"<br />

Side Up<br />

3. TO install the balance of the rings, use a ring<br />

tool with recess side up and place the ring in<br />

with the bottom side up. Start with the lowest<br />

ring first.<br />

Some piston rings are taper faced. These are<br />

clearly marked "TOP" on the side to be up when<br />

assembled on piiston.<br />

4. Position ring in the tool so the expanding<br />

fingers will fully engage both ends.<br />

5. Apply pressure on handles so ring is completely<br />

expanded. Pass the expanded ring and tool<br />

recessed side down over the piston to the proper<br />

groove.<br />

CAUTION<br />

if piston is equipped with a steel groove insert, this must be<br />

installed on top of the number one ring. (The steel groove<br />

insert is not part of the re-ring kit ~ this can be re-used when<br />

replacing rings.)<br />

6. Check the ring side clearance at various positions<br />

with a feeler in accordance with the tolerances<br />

shown on the Limits and Clearance Chart.<br />

Figure 138--Checking Ring Clearance in Groove<br />

CONTINENTAL L-HEAD ENGINE MANUAL Page 61<br />

CRANKSHAFT AND MAIN<br />

BEARINGS<br />

1. Using a puller, remove pulley from crankshaft.<br />

2. Take out screws and remove gear cover.<br />

3. Drop the oil pump, by removing nut or cap<br />

screws holding pump to center main bearing cap.<br />

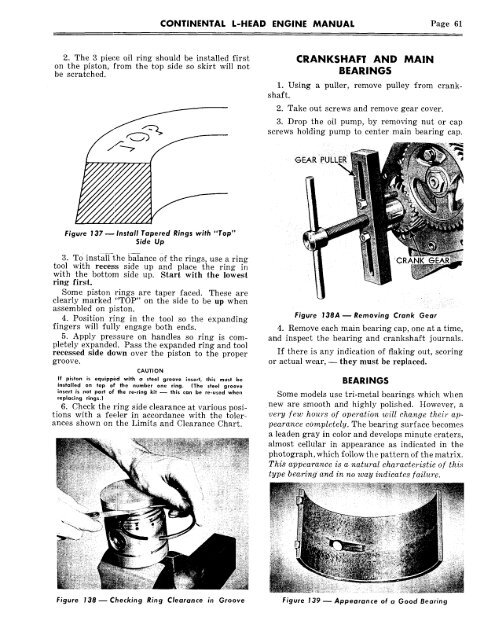

GEAR PULLER<br />

CRANK GEAR<br />

Figur.e 138A m Removing Crank Gear<br />

4. Remove each main bearing cap, one at a time,<br />

and inspect the bearing and crankshaft journals.<br />

If there is any indication of flaking out, scoring<br />

or actual wear, -- they must be replaced.<br />

BEARINGS<br />

Some models use tri-metal bearings which when<br />

new are smooth and highly polished. However, a<br />

very few hours of operation will change their appearance<br />

completely. The bearing surface becomes<br />

a leaden gray in color and develops minute craters,<br />

almost cellular in appearance as indicated in the<br />

photograph, which follow the pattern of the matrix.<br />

This appearance is a natural characteristic of this<br />

type bearing’ and in no way indicates failure.<br />

Figure 139 ~ Appearance of a Good Bearing