Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 50 CONTINENTAL L-HEAD ENGINE MANUAL<br />

The ratio of turns in the coil secondary winding<br />

to those of the primary is very high so the induced<br />

voltage in the secondary winding is also very high.<br />

The self-induced voltage occurring in the primary<br />

winding, as a result of the quick break of the<br />

All magnetos have an impulse coupling which<br />

assists starting by automatically retarding the<br />

ignition spark during the starting operation and<br />

at the same time producing an intense, hot spark<br />

-- which would otherwise be impossible at very<br />

low engine speeds.<br />

This device prevents the rotor of the magneto<br />

from turning during the starting operation until<br />

the engine piston is about at top-dead-center, at<br />

which instant the rotor is snapped forward at very<br />

high speed, producing an intense spark which is<br />

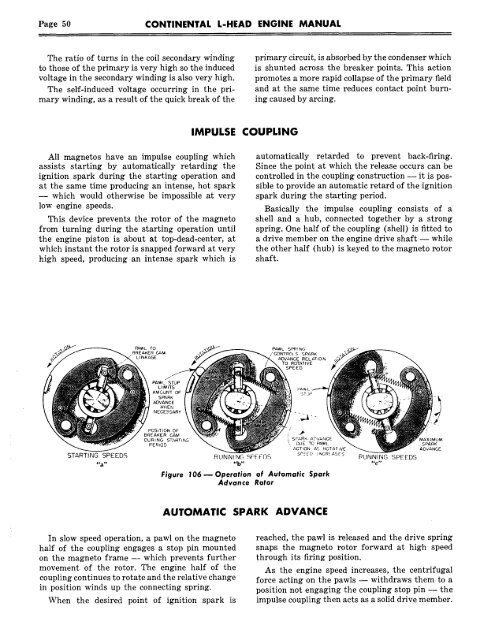

STARTING SPEEDS<br />

PAWL rO<br />

BREAKER ChM<br />

LINKAGE<br />

PAWL STOP<br />

L I M I’f S<br />

AMCUNT OF<br />

SPARK<br />

.&DVANC[<br />

WH E f;<br />

NECESSARY<br />

In slow speed operation, a pawl on the magneto<br />

half of the coupling engages a stop pin mounted<br />

on the magneto frame -- which prevents further<br />

movement of the rotor. The engine half of the<br />

coupling continues to rotate and the relative change<br />

in position winds up the connecting spring.<br />

When the desired point of ignition spark is<br />

IMPULSE COUPLING<br />

RUNNING SPFFOS<br />

primary circuit, is absorbed by the condenser which<br />

is shunted across the breaker points. This action<br />

promotes a more rapid collapse of the primary field<br />

and at the same time reduces contact point burning<br />

caused by arcing.<br />

automatically retarded to prevent back~firing.<br />

Since the point at which the release occurs can be<br />

controlled in the coupling construction -- it is possible<br />

to provide an automatic retard of the ignition<br />

spark during the starting period.<br />

Basically the impulse coupling consists of a<br />

shell and a hub, connected together by a strong<br />

spring. One half of the coupling (shell) is fitted<br />

a drive member on the engine drive shaft -- while<br />

the other half (hub) is keyed to the magneto ~otor<br />

shaft.<br />

PAWL SPRING<br />

/’~ONTRC}I S SPARK<br />

A(~VANCE RELATION<br />

TO ROTATIV E<br />

SPEED<br />

Figure 106 ~ Operation of Automatic Spark<br />

Advance Rotor<br />

AUTOMATIC SPARK ADVANCE<br />

reached, the pawl is released and the drive spring<br />

snaps the magneto rotor forward at high speed<br />

through its firing position.<br />

As the engine speed increases, the centrifugal<br />

force acting on the pawls -- withdraws them to a<br />

position not engaging the coupling stop pin -- the<br />

impulse coupling then acts as a solid drive member.