Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Figure 101 ~ Faulty spark plugs. Left: cold plug used<br />

in an engine that should have a hot plug. Right: hot<br />

plug used in ar~ engine that should have a cold plug.<br />

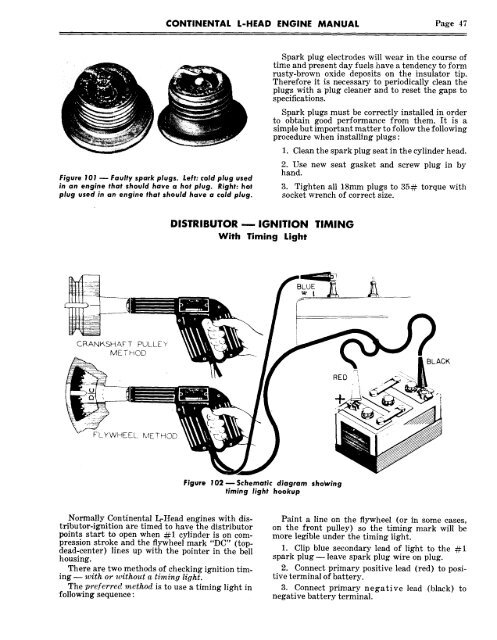

C_.RANK, SHAFT PULLEY<br />

METHOD<br />

FLYWHEEL k~lE THOD<br />

Normally <strong>Continental</strong> L-<strong>Head</strong> engines with distributor-ignition<br />

are timed to have the distributor<br />

points start to open when ¢~1 cylinder is on compression<br />

stroke and the flywheel mark "DC" (topdead-center)<br />

lines up with the pointer in the bell<br />

housing.<br />

There are two methods of checking ignition timing<br />

-- with or without a timing light.<br />

The preferred method is to use a timing light in<br />

following sequence:<br />

CONTINENTAL L-HEAD ENGINE MANUAL Page 47<br />

DISTRIBUTOR -- IGNITION TIMING<br />

With Timing Light<br />

Spark plug electrodes will wear in the course of<br />

time and present day fuels have a tendency to form<br />

rusty-brown oxide deposits on the insulator tip.<br />

Therefore it is necessary to periodically clean the<br />

plugs with & plug cleaner and to reset the gaps to<br />

specifications.<br />

Sp&rk plugs must be correctly installed in order<br />

to obtain good performance from them. It is a<br />

simple but important matter to follow the following<br />

procedure when installing plugs:<br />

1. Clean the spark plug seat in the cylinder head.<br />

2. Use new seat gasket and screw plug in by<br />

hand.<br />

3. Tighten all 18mm plugs to 35¢~ torque with<br />

socket wrench of correct size.<br />

BLUE<br />

~ I<br />

RED<br />

Figure 102-- Schematic diagram sho~ving<br />

timing light hookup<br />

Paint a line on the flywheel (or in some cases,<br />

on the front pulley) so the timing mark will be<br />

more legible under the timing light.<br />

1. Clip blue secondary lead of light to the<br />

spark plug -- leave spark plug wire on plug.<br />

2. Connect primary positive lead (red) to positive<br />

terminal of battery.<br />

3. Connect primary negative lead (black)<br />

negative battery terminal.