Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 34 CONTINENTAL L-HEAD ENGINE MANUAL<br />

REMOVING WATER PUMP<br />

The water pump assembly can be removed from<br />

the engine as a unit for service or repair in the<br />

following manner:<br />

1. Remove fan by taking out four cap screws.<br />

2. Loosen generator so that fan belt can be<br />

slacked off enough to slide over pulley.<br />

3. Remove nuts and lockwashers holding the<br />

pump body to the front of the block and remove<br />

the pump assembly.<br />

Figure 75--Removing Wafer Pump<br />

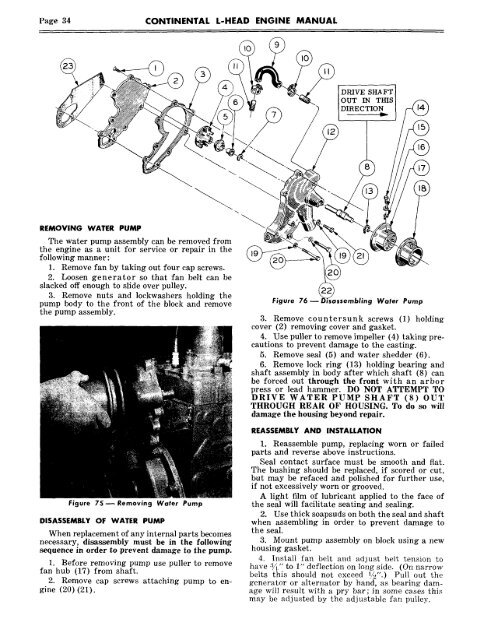

DISASSEMBLY OF WATER PUMP<br />

When replacement of any internal parts becomes<br />

necessary, disassembly must be in the following<br />

sequence in order to prevent damage to the pump.<br />

1. Before removing pump use puller to remove<br />

fan hub (17) from shaft.<br />

2. Remove cap screws attaching pump to engine<br />

(20) (21).<br />

DRIVE SHA FT<br />

OUT IN THIS<br />

DIRECTION<br />

Figure 76-- fssembling Water Pump<br />

3. Remove countersunk screws (1) holding"<br />

cover (2) removing cover and gasket.<br />

4. Use puller to remove impeller (4) taking precautions<br />

to prevent damage to the casting.<br />

5. Remove seal (5) and water shedder (6).<br />

6. Remove lock ring (13) holding bearing and<br />

shaft assembly in body after which shaft (8) can<br />

be forced out through the front with an arbor<br />

press or lead hammer. DO NOT ATTEMPT TO<br />

DRIVE WATER PUMP SHAFT (8) OUT<br />

THROUGH REAR OF HOUSING. To do so will<br />

damage the housing beyond repair.<br />

REASSEMBLY AND INSTALLATION<br />

1. Reassemble pump, replacing worn or failed<br />

parts and reverse above instructions.<br />

Seal contact surface must be smooth and flat.<br />

The bushing should be replaced, if scored or ~ut,<br />

but may be refaced and polished for further use,<br />

if not excessively worn or grooved.<br />

A light film of lubricant applied to the face of<br />

the seal will facilitate seating and sealing.<br />

2. Use thick soapsuds on both the seal and shaft<br />

when assembling in order to prevent damage to<br />

the seal.<br />

3. Mount pump assembly on block using a new<br />

housing gasket.<br />

4. Install fan belt and adjust be~t tension to<br />

have :~/~," to 1" deflection on long side. (On narrow<br />

belts this should not exceed ~,/~".) Pull out the<br />

generator or alternator by hand, as bearing damage<br />

will result with a pry bar; in some cases this<br />

may be adjusted by the adjustable fan pulley.