Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 68 CONTINENTAL L-HEAD ENGINE MANUAL<br />

FRONT FILLER BLOCK,<br />

Figure 163 ~ Installing Neoprene Seal in Front<br />

Filler Block<br />

2. Neoprene seal on front filler block is installed<br />

in the same manner.<br />

When replacing gear cover, cement gasket to<br />

gear cover with a quick drying gasket cement and<br />

reassemble to engine block.<br />

Figure 164 ~ Neoprene Seals in Place<br />

In order to prevent possible oil leaks, it is imperative<br />

to use only genuine <strong>Continental</strong> replacement<br />

gaskets and seals--since these have been engineered<br />

and designed to do a superlative job.<br />

NEOPRENE CIRCULAR SPRING TYPE SEAL<br />

The "N" series of engines uses a circular spring<br />

type seal which is replaced as follows:<br />

1. Remove flywheel assembly.<br />

2. Remove cap screws from oil seal retainer assembly.<br />

3. Remove retainer from 2 dowel pins and slide<br />

off seal surface of crankshaft.<br />

4. Press oil seal from retainer with a driver<br />

slightly smaller than seal diameter. Thoroughly<br />

clean back of cylinder block and retainer in a<br />

solvent.<br />

5. On an arbor press, press in new seal with driver<br />

which fits oil seal to prevent damage to seal.<br />

If a driver of the correct diameter is not avail-<br />

OIL SEAL<br />

RETAINER<br />

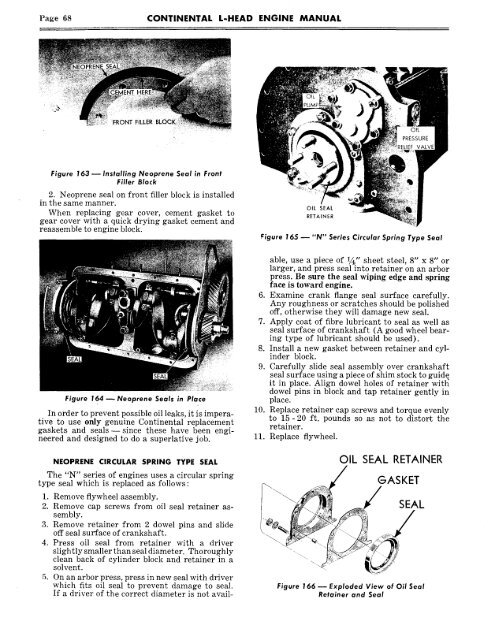

f:igure 165 ~ "N" Series Circular Spring Type Seal<br />

able, use a piece of 1/~,, sheet steel, 8" x 8" or<br />

larger, and press seal into retainer on an arbor<br />

press. Be sure the seal wiping edge and spring<br />

face is toward engine.<br />

6. Examine crank flange seal surface carefully.<br />

Any roughness or scratches should be polished<br />

off, otherwise they will damage new seal.<br />

7. Apply coat of fibre lubricant to seal as well as<br />

seal surface of crankshaft (A good wheel bearing<br />

type of lubricant should be used).<br />

8. Install a new gasket between retainer and cylinder<br />

block.<br />

9. Carefully slide seal assembly over crankshaft<br />

seal surface using a piece of shim stock to guide<br />

it in place. Align dowel holes of retainer witl~<br />

dowel pins in block and tap retainer gently in<br />

place.<br />

10. Replace retainer cap screws and torque evenly<br />

to 15-20 ft. pounds so as not to distort the<br />

retainer.<br />

11. Replace flywheel.<br />

OIL SEAL RETAINER<br />

GASKET<br />

SEAL<br />

Figure 166 m Exploded View of Oil Seal<br />

Retainer and Seal