Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 64 CONTINENTAL L-HEAD ENGINE MANUAL<br />

CAMSHAFT<br />

1. Using a puller, remove the cam and crank<br />

gears.<br />

Figure 149 m Removing Cam Gear with Puller<br />

2. Remove the screws holding the camshaft<br />

thrust plate to the front of the cylinder block,<br />

which makes it possible to pull the camshaft forward<br />

out of the bearings.<br />

3. Unless engine is lying on its side, tappets<br />

must be removed or lifted before camshaft can be<br />

pulled.<br />

4. Remove tappet chamber covers.<br />

5. Tappets can then be lifted out and lined up<br />

in sequence, for installation in the same location<br />

unless inspection shows that they require replacement.<br />

6. Before pulling the camshaft completely, check<br />

the clearance of the bearing journals in the bushing<br />

(or block in some models). To do this use strips<br />

of feeler stock 1/~,, wide with edges dressed with<br />

a stone to eliminate any burrs or feathered edges.<br />

7. If clearance is equal to or greater than the<br />

amount indicated under wear limits, check the<br />

diameter of the camshaft journals to determine the<br />

next step. Excess wear at these positions require<br />

replacement of the shaft.<br />

If wear is found to be in the bushings instead,<br />

these must be replaced using precision service<br />

bushings, available for that purpose, which require<br />

no reaming, only care in assembly, to line up oil<br />

holes, and not to damage the bushings as they are<br />

being pressed in.<br />

TAPPETS<br />

ACCEPTABLE NOT ACCEPTABLE<br />

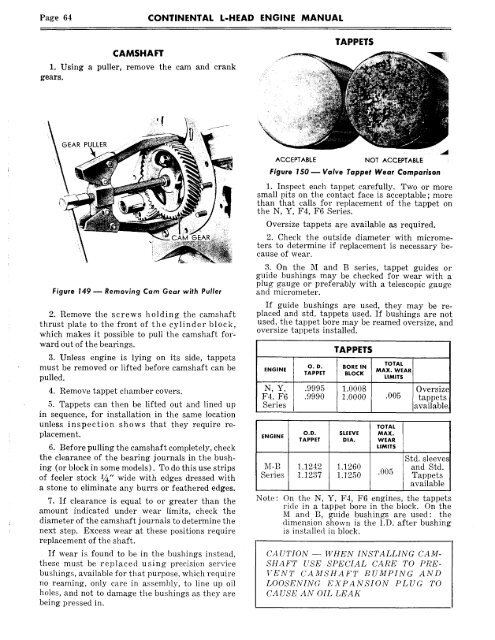

Figure 150 m Valve Tappet Wear Comparison<br />

1. Inspect each tappet carefully. Two o1" more<br />

small pits on the contact face is acceptable; more<br />

than that calls for replacement of the tappet on<br />

the N, Y, F4, F6 Series.<br />

Oversize tappets are available as required.<br />

2. Check the outside diameter with micrometers<br />

to determine if replacement is necessary because<br />

of wear.<br />

3. On the M and B series, tappet guides or<br />

guide bushings may be checked for wear with a<br />

plug gauge or preferably with a telescopic gauge<br />

and micrometer.<br />

If guide bushings are used, they may be replaced<br />

and std. tappets used. If bushings are not<br />

used, the tappet bore may be reamed oversize, and<br />

oversize tappets installed.<br />

TAPPETS<br />

TOTAL<br />

ENGINE<br />

O.D. BORE IN<br />

MAX. WEAR<br />

TAPPET BLOCK<br />

LIMITS<br />

N, Y, .9995 1.0008 Oversize<br />

F4, F6 .9990 1.0000 .005 tappets<br />

Series available,<br />

ENGINE<br />

M-B<br />

Series<br />

O.D. SLEEVE<br />

TAPPET DIA.<br />

1.1242 1.1260<br />

1.1237 1.1250<br />

TOTAL<br />

MAX.<br />

WEAR<br />

LIMITS<br />

.005<br />

Std. sleeves<br />

and Std.<br />

Tappets<br />

available<br />

Note: On the N, Y, F4, F6 engines, the tappets<br />

ride in a tappet bore in the block. On the<br />

M and B, guide bushings are used: the<br />

dimension shown is the I.D. after bushing<br />

is installed in block.<br />

CAUTION -- WHEN INSTALLING CAM-<br />

SHAFT USE SPECIAL CARE TO PRE-<br />

VENT CAMSHAFT BUMPING AND<br />

LOOSENING EXPANSION PLUG TO<br />

CA USE AN OIL LEAK