SIMATIC PCS 7 Process Control System - Siemens

SIMATIC PCS 7 Process Control System - Siemens

SIMATIC PCS 7 Process Control System - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Typical sequence of a maintenance cycle<br />

• Intelligent sensors recognize the threat of failures by means of<br />

the implemented diagnostics system long before the actual<br />

failure, and can signal these.<br />

• Diagnostics information on network components and basic<br />

PC devices is transferred to the maintenance station via an<br />

OPC SNMP link present in the assets.<br />

• The symbol of the associated component (e.g. a field device)<br />

signals "Maintenance required" on the maintenance station.<br />

An entry is automatically made in the message log so that the<br />

chronology of occurred events can also be analyzed later.<br />

Parallel to this, the vendor’s detailed diagnostics information is<br />

determined by means of <strong>SIMATIC</strong> PDM and the device description<br />

(EDD).<br />

• On the overview display, maintenance engineers recognize<br />

"Maintenance required" in the technological plant. The maintenance<br />

engineers are rapidly guided to the corresponding device<br />

using standard mechanisms known from the operator station<br />

such as "Common display" and "Operator prompting<br />

using loop in alarm". Important information is then shown in the<br />

faceplate of the associated device, e.g. process tag number,<br />

location and device type.<br />

• The existing detailed diagnostics information on the problem<br />

can then be called using the "Diagnostics" view depending on<br />

the device type and vendor, e.g. fault description, cause,<br />

trend information or handling instructions.<br />

• They can assess the fault in the "Maintenance" view, and initiate<br />

corresponding reactions. This can be e.g. the input of a<br />

comment or handling instruction, the assignment of a work instruction<br />

number, or the increasing/decreasing of the maintenance<br />

requirement priority depending on the significance for<br />

the technological plant. Current working measures can also<br />

be traced/accompanied in this view. All operations can be<br />

logged. The log also contains the faceplate contents with ID<br />

data, messages, detailed diagnostics information, work instructions,<br />

notes and status.<br />

• The work request with all information gained on the maintenance<br />

station is passed on to the corresponding maintenance<br />

department (identified by symbol "Maintenance order requested").<br />

The release for maintenance of the component can<br />

also be made on the maintenance station (identified by symbol<br />

"Maintenance order being processed"). The current status<br />

of the maintenance measure is then indicated for all involved<br />

parties, and also for subsequent shifts.<br />

• Once the maintenance measure has been carried out, it is<br />

concluded on the maintenance station – the status displays<br />

then return to the normal state. The complete maintenance cycle<br />

is documented on the maintenance station without gaps –<br />

automatically and without additional configuration overhead.<br />

© <strong>Siemens</strong> AG 2007<br />

Asset Management<br />

Maintenance station<br />

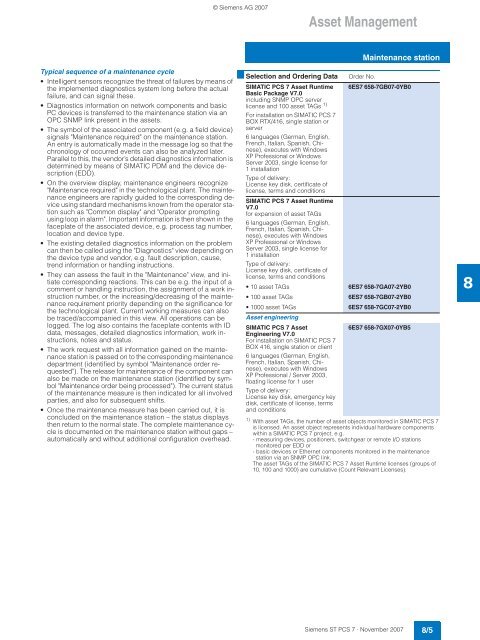

■ Selection and Ordering Data Order No.<br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 Asset Runtime<br />

Basic Package V7.0<br />

including SNMP OPC server<br />

license and 100 asset TAGs 1)<br />

6ES7 658-7GB07-0YB0<br />

For installation on <strong>SIMATIC</strong> <strong>PCS</strong> 7<br />

BOX RTX/416, single station or<br />

server<br />

6 languages (German, English,<br />

French, Italian, Spanish, Chinese),<br />

executes with Windows<br />

XP Professional or Windows<br />

Server 2003, single license for<br />

1 installation<br />

Type of delivery:<br />

License key disk, certificate of<br />

license, terms and conditions<br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 Asset Runtime<br />

V7.0<br />

for expansion of asset TAGs<br />

6 languages (German, English,<br />

French, Italian, Spanish, Chinese),<br />

executes with Windows<br />

XP Professional or Windows<br />

Server 2003, single license for<br />

1 installation<br />

Type of delivery:<br />

License key disk, certificate of<br />

license, terms and conditions<br />

•10 asset TAGs 6ES7 658-7GA07-2YB0<br />

• 100 asset TAGs 6ES7 658-7GB07-2YB0<br />

• 1000 asset TAGs 6ES7 658-7GC07-2YB0<br />

Asset engineering<br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 Asset<br />

6ES7 658-7GX07-0YB5<br />

Engineering V7.0<br />

For installation on <strong>SIMATIC</strong> <strong>PCS</strong> 7<br />

BOX 416, single station or client<br />

6 languages (German, English,<br />

French, Italian, Spanish, Chinese),<br />

executes with Windows<br />

XP Professional / Server 2003,<br />

floating license for 1 user<br />

Type of delivery:<br />

License key disk, emergency key<br />

disk, certificate of license, terms<br />

and conditions<br />

1) With asset TAGs, the number of asset objects monitored in <strong>SIMATIC</strong> <strong>PCS</strong> 7<br />

is licensed. An asset object represents individual hardware components<br />

within a <strong>SIMATIC</strong> <strong>PCS</strong> 7 project, e.g.<br />

- measuring devices, positioners, switchgear or remote I/O stations<br />

monitored per EDD or<br />

- basic devices or Ethernet components monitored in the maintenance<br />

station via an SNMP OPC link.<br />

The asset TAGs of the <strong>SIMATIC</strong> <strong>PCS</strong> 7 Asset Runtime licenses (groups of<br />

10, 100 and 1000) are cumulative (Count Relevant Licenses).<br />

<strong>Siemens</strong> ST <strong>PCS</strong> 7 · November 2007<br />

8/5<br />

8