SIMATIC PCS 7 Process Control System - Siemens

SIMATIC PCS 7 Process Control System - Siemens

SIMATIC PCS 7 Process Control System - Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

■ Overview<br />

Fault-tolerant automation systems are used to reduce the risk of<br />

production failures. The higher investment costs for fault-tolerant<br />

automation systems are frequently negligible compared to the<br />

costs resulting from production failures. The higher the costs of<br />

a production failure, the more worthwhile it is to use a fault-tolerant<br />

system.<br />

Fault-tolerant automation systems can be mounted in a UR2-H<br />

compact rack with divided backplane bus or in two separate<br />

racks (UR1 or UR2). The design in two racks allows physical<br />

separation of the redundant subsystems, e.g. by a fireproof partition.<br />

Fault-tolerant automation systems can be used on their own in a<br />

plant configuration, or together with standard and safety-related<br />

automation systems.<br />

© <strong>Siemens</strong> AG 2008<br />

Automation systems<br />

Fault-tolerant automation systems<br />

■ Design<br />

Fault-tolerant automation systems for <strong>SIMATIC</strong> <strong>PCS</strong> 7 are available<br />

as preassembled and tested all-in-one systems (AS bundles)<br />

at no extra charge.<br />

Depending on the type of automation system, the RAM of these<br />

AS bundles varies as follows:<br />

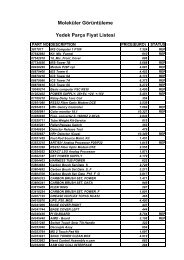

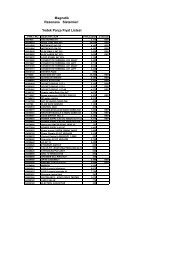

AS type Main memory<br />

AS 412H 768 KB (512 KB for program and 256 KB for data)<br />

AS 414H 2.8 MB (1.4 MB each for program and data)<br />

AS 417H 30 MB (15 MB each for program and data)<br />

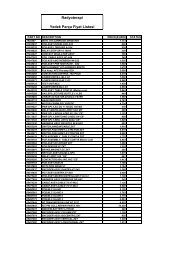

Runtime licenses<br />

Each AS bundle is already provided as standard with the<br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 AS Runtime license for 100 process objects<br />

(PO). The number of process objects can be extended by additional<br />

Runtime licenses for 100, 1000 or 10000 POs. The process<br />

objects of additional Runtime licenses can be added to process<br />

objects which already exist. The number and type (e.g. 100 or<br />

1000) of additional Runtime licenses are irrelevant. The AS Runtime<br />

licenses are administered on a <strong>SIMATIC</strong> <strong>PCS</strong> 7 engineering<br />

system or in the <strong>SIMATIC</strong> <strong>PCS</strong> 7 BOX.<br />

Connection of process I/Os<br />

Several PROFIBUS DP lines with distributed process I/Os can be<br />

operated on each sub-AS through the internal PROFIBUS DP interface<br />

or by using additional communications processors.<br />

• The ET 200M remote I/O stations are connected via two<br />

IM 153-2 High Feature interface modules on a special bus<br />

module to two redundant PROFIBUS DP segments.<br />

• The intelligent field devices on the PROFIBUS PA are connected<br />

over a DP/PA link to two redundant IM 153-2 High<br />

Feature interface modules.<br />

• Non-redundant PROFIBUS DP devices, e.g. ET 200S<br />

distributed I/O devices, can be connected to the redundant<br />

PROFIBUS DP over the Y-link.<br />

These configurations can also be mixed together.<br />

Communication over the plant bus<br />

The AS 412H, AS 414H and AS 417H automation systems are<br />

connected as standard by one communications processor per<br />

sub-AS to the plant bus.<br />

The plant bus can be implemented in the form of a ring structure,<br />

which can also be configured with redundant architecture if the<br />

availability requirements are high. When there are two redundant<br />

rings it makes sense to use two communications processors<br />

per sub-AS and to distribute their connections between the two<br />

rings (4-way connection). Double faults such as failure of the<br />

OSM/SCALANCE switch on ring 1 with simultaneous interruption<br />

in the bus cable on ring 2 can thus be tolerated.<br />

<strong>Siemens</strong> ST <strong>PCS</strong> 7 · Update November 2008<br />

10/15<br />

10