Identification of the major drivers of 'phenolic' taste in ... - GWRDC

Identification of the major drivers of 'phenolic' taste in ... - GWRDC

Identification of the major drivers of 'phenolic' taste in ... - GWRDC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AWRI: <strong>Identification</strong> Of The Major Drivers Of ‘Phenolic’ Taste In White W<strong>in</strong>es<br />

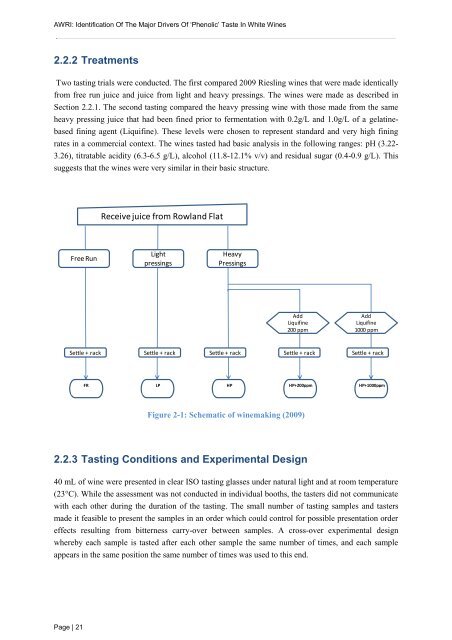

2.2.2 Treatments<br />

Two tast<strong>in</strong>g trials were conducted. The first compared 2009 Riesl<strong>in</strong>g w<strong>in</strong>es that were made identically<br />

from free run juice and juice from light and heavy press<strong>in</strong>gs. The w<strong>in</strong>es were made as described <strong>in</strong><br />

Section 2.2.1. The second tast<strong>in</strong>g compared <strong>the</strong> heavy press<strong>in</strong>g w<strong>in</strong>e with those made from <strong>the</strong> same<br />

heavy press<strong>in</strong>g juice that had been f<strong>in</strong>ed prior to fermentation with 0.2g/L and 1.0g/L <strong>of</strong> a gelat<strong>in</strong>e-<br />

based f<strong>in</strong><strong>in</strong>g agent (Liquif<strong>in</strong>e). These levels were chosen to represent standard and very high f<strong>in</strong><strong>in</strong>g<br />

rates <strong>in</strong> a commercial context. The w<strong>in</strong>es <strong>taste</strong>d had basic analysis <strong>in</strong> <strong>the</strong> follow<strong>in</strong>g ranges: pH (3.22-<br />

3.26), titratable acidity (6.3-6.5 g/L), alcohol (11.8-12.1% v/v) and residual sugar (0.4-0.9 g/L). This<br />

suggests that <strong>the</strong> w<strong>in</strong>es were very similar <strong>in</strong> <strong>the</strong>ir basic structure.<br />

Page | 21<br />

Free Run<br />

FR<br />

EW1 001-003<br />

Receive juice from Rowland Flat<br />

Light<br />

press<strong>in</strong>gs<br />

LP<br />

EW1 004-006<br />

Heavy<br />

Press<strong>in</strong>gs<br />

Settle + rack Settle + rack Settle + rack<br />

HP<br />

EW1 007-009<br />

Add<br />

Liquif<strong>in</strong>e<br />

200 ppm<br />

HP+200ppm<br />

EW1 010-012<br />

Figure 2-1: Schematic <strong>of</strong> w<strong>in</strong>emak<strong>in</strong>g (2009)<br />

2.2.3 Tast<strong>in</strong>g Conditions and Experimental Design<br />

40 mL <strong>of</strong> w<strong>in</strong>e were presented <strong>in</strong> clear ISO tast<strong>in</strong>g glasses under natural light and at room temperature<br />

(23°C). While <strong>the</strong> assessment was not conducted <strong>in</strong> <strong>in</strong>dividual booths, <strong>the</strong> <strong>taste</strong>rs did not communicate<br />

with each o<strong>the</strong>r dur<strong>in</strong>g <strong>the</strong> duration <strong>of</strong> <strong>the</strong> tast<strong>in</strong>g. The small number <strong>of</strong> tast<strong>in</strong>g samples and <strong>taste</strong>rs<br />

made it feasible to present <strong>the</strong> samples <strong>in</strong> an order which could control for possible presentation order<br />

effects result<strong>in</strong>g from bitterness carry-over between samples. A cross-over experimental design<br />

whereby each sample is <strong>taste</strong>d after each o<strong>the</strong>r sample <strong>the</strong> same number <strong>of</strong> times, and each sample<br />

appears <strong>in</strong> <strong>the</strong> same position <strong>the</strong> same number <strong>of</strong> times was used to this end.<br />

Add<br />

Liquif<strong>in</strong>e<br />

1000 ppm<br />

Settle + rack Settle + rack<br />

HP+1000ppm<br />

EW1 013-015