Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

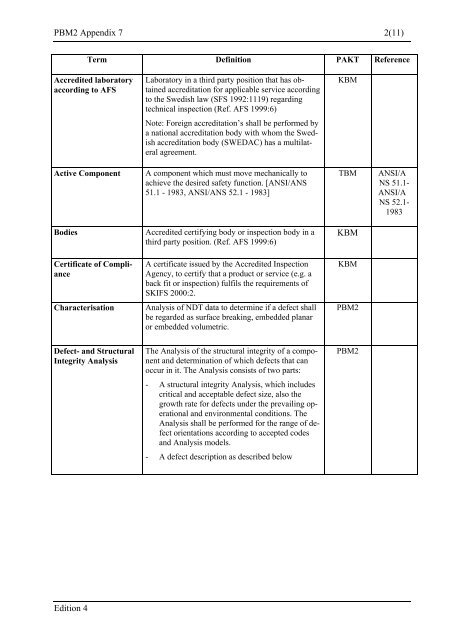

PBM2 Appendix 7 2(11)<br />

Edition 4<br />

Term Def<strong>in</strong>ition PAKT Reference<br />

Accredited laboratory<br />

accord<strong>in</strong>g to AFS<br />

Laboratory <strong>in</strong> a third party position that has obta<strong>in</strong>ed<br />

accreditation <strong>for</strong> applicable service accord<strong>in</strong>g<br />

to the Swedish law (SFS 1992:1119) regard<strong>in</strong>g<br />

technical <strong>in</strong>spection (Ref. AFS 1999:6)<br />

Note: Foreign accreditation’s shall be per<strong>for</strong>med by<br />

a national accreditation body with whom the Swedish<br />

accreditation body (SWEDAC) has a multilateral<br />

agreement.<br />

Active Component A component which must move mechanically to<br />

achieve the desired safety function. [ANSI/ANS<br />

51.1 - 1983, ANSI/ANS 52.1 - 1983]<br />

Bodies Accredited certify<strong>in</strong>g body or <strong>in</strong>spection body <strong>in</strong> a<br />

third party position. (Ref. AFS 1999:6)<br />

Certificate <strong>of</strong> Compliance<br />

A certificate issued by the Accredited Inspection<br />

Agency, to certify that a product or service (e.g. a<br />

back fit or <strong>in</strong>spection) fulfils the requirements <strong>of</strong><br />

SKIFS 2000:2.<br />

Characterisation Analysis <strong>of</strong> <strong>NDT</strong> data to determ<strong>in</strong>e if a defect shall<br />

be regarded as surface break<strong>in</strong>g, embedded planar<br />

or embedded volumetric.<br />

Defect- and Structural<br />

Integrity Analysis<br />

The Analysis <strong>of</strong> the structural <strong>in</strong>tegrity <strong>of</strong> a component<br />

and determ<strong>in</strong>ation <strong>of</strong> which defects that can<br />

occur <strong>in</strong> it. The Analysis consists <strong>of</strong> two parts:<br />

- A structural <strong>in</strong>tegrity Analysis, which <strong>in</strong>cludes<br />

critical and acceptable defect size, also the<br />

growth rate <strong>for</strong> defects under the prevail<strong>in</strong>g operational<br />

and environmental conditions. The<br />

Analysis shall be per<strong>for</strong>med <strong>for</strong> the range <strong>of</strong> defect<br />

orientations accord<strong>in</strong>g to accepted codes<br />

and Analysis models.<br />

- A defect description as described below<br />

KBM<br />

TBM ANSI/A<br />

NS 51.1-<br />

ANSI/A<br />

NS 52.1-<br />

1983<br />

KBM<br />

KBM<br />

PBM2<br />

PBM2