Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

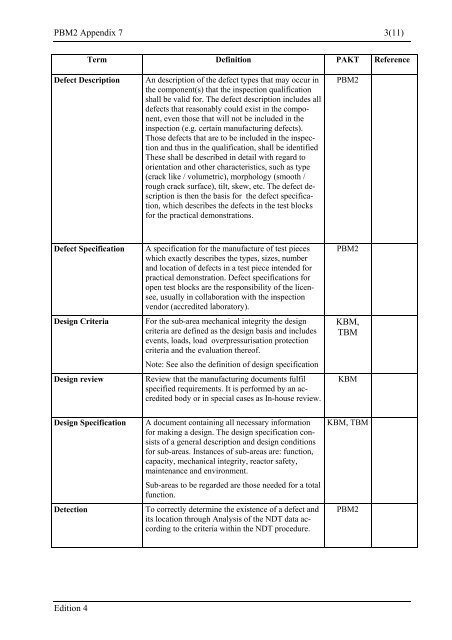

PBM2 Appendix 7 3(11)<br />

Edition 4<br />

Term Def<strong>in</strong>ition PAKT Reference<br />

Defect Description An description <strong>of</strong> the defect types that may occur <strong>in</strong><br />

the component(s) that the <strong>in</strong>spection <strong>qualification</strong><br />

shall be valid <strong>for</strong>. The defect description <strong>in</strong>cludes all<br />

defects that reasonably could exist <strong>in</strong> the component,<br />

even those that will not be <strong>in</strong>cluded <strong>in</strong> the<br />

<strong>in</strong>spection (e.g. certa<strong>in</strong> manufactur<strong>in</strong>g defects).<br />

Those defects that are to be <strong>in</strong>cluded <strong>in</strong> the <strong>in</strong>spection<br />

and thus <strong>in</strong> the <strong>qualification</strong>, shall be identified<br />

These shall be described <strong>in</strong> detail with regard to<br />

orientation and other characteristics, such as type<br />

(crack like / volumetric), morphology (smooth /<br />

rough crack surface), tilt, skew, etc. The defect description<br />

is then the basis <strong>for</strong> the defect specification,<br />

which describes the defects <strong>in</strong> the test blocks<br />

<strong>for</strong> the practical demonstrations.<br />

Defect Specification A specification <strong>for</strong> the manufacture <strong>of</strong> test pieces<br />

which exactly describes the types, sizes, number<br />

and location <strong>of</strong> defects <strong>in</strong> a test piece <strong>in</strong>tended <strong>for</strong><br />

practical demonstration. Defect specifications <strong>for</strong><br />

open test blocks are the responsibility <strong>of</strong> the licensee,<br />

usually <strong>in</strong> collaboration with the <strong>in</strong>spection<br />

vendor (accredited laboratory).<br />

Design Criteria For the sub-area mechanical <strong>in</strong>tegrity the design<br />

criteria are def<strong>in</strong>ed as the design basis and <strong>in</strong>cludes<br />

events, loads, load overpressurisation protection<br />

criteria and the evaluation there<strong>of</strong>.<br />

Note: See also the def<strong>in</strong>ition <strong>of</strong> design specification<br />

Design review Review that the manufactur<strong>in</strong>g documents fulfil<br />

specified requirements. It is per<strong>for</strong>med by an accredited<br />

body or <strong>in</strong> special cases as In-house review.<br />

Design Specification A document conta<strong>in</strong><strong>in</strong>g all necessary <strong>in</strong><strong>for</strong>mation<br />

<strong>for</strong> mak<strong>in</strong>g a design. The design specification consists<br />

<strong>of</strong> a general description and design conditions<br />

<strong>for</strong> sub-areas. Instances <strong>of</strong> sub-areas are: function,<br />

capacity, mechanical <strong>in</strong>tegrity, reactor safety,<br />

ma<strong>in</strong>tenance and environment.<br />

Sub-areas to be regarded are those needed <strong>for</strong> a total<br />

function.<br />

Detection To correctly determ<strong>in</strong>e the existence <strong>of</strong> a defect and<br />

its location through Analysis <strong>of</strong> the <strong>NDT</strong> data accord<strong>in</strong>g<br />

to the criteria with<strong>in</strong> the <strong>NDT</strong> procedure.<br />

PBM2<br />

PBM2<br />

KBM,<br />

TBM<br />

KBM<br />

KBM, TBM<br />

PBM2