Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

Rules for qualification of NDT systems in Sweden (PDF ... - Vattenfall

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

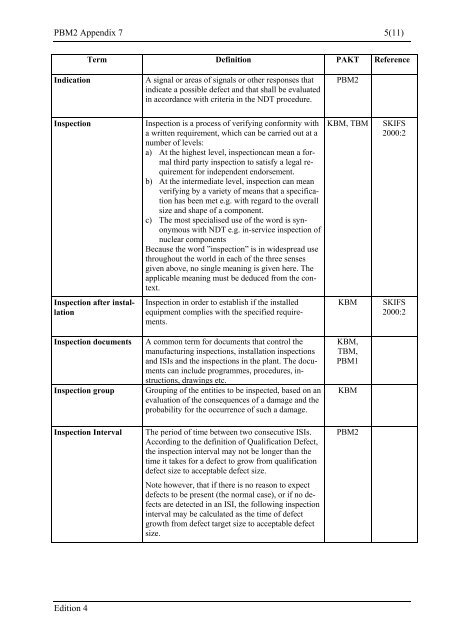

PBM2 Appendix 7 5(11)<br />

Edition 4<br />

Term Def<strong>in</strong>ition PAKT Reference<br />

Indication A signal or areas <strong>of</strong> signals or other responses that<br />

<strong>in</strong>dicate a possible defect and that shall be evaluated<br />

<strong>in</strong> accordance with criteria <strong>in</strong> the <strong>NDT</strong> procedure.<br />

Inspection Inspection is a process <strong>of</strong> verify<strong>in</strong>g con<strong>for</strong>mity with<br />

a written requirement, which can be carried out at a<br />

number <strong>of</strong> levels:<br />

a) At the highest level, <strong>in</strong>spectioncan mean a <strong>for</strong>mal<br />

third party <strong>in</strong>spection to satisfy a legal requirement<br />

<strong>for</strong> <strong>in</strong>dependent endorsement.<br />

b) At the <strong>in</strong>termediate level, <strong>in</strong>spection can mean<br />

verify<strong>in</strong>g by a variety <strong>of</strong> means that a specification<br />

has been met e.g. with regard to the overall<br />

size and shape <strong>of</strong> a component.<br />

c) The most specialised use <strong>of</strong> the word is synonymous<br />

with <strong>NDT</strong> e.g. <strong>in</strong>-service <strong>in</strong>spection <strong>of</strong><br />

nuclear components<br />

Because the word ”<strong>in</strong>spection” is <strong>in</strong> widespread use<br />

throughout the world <strong>in</strong> each <strong>of</strong> the three senses<br />

given above, no s<strong>in</strong>gle mean<strong>in</strong>g is given here. The<br />

applicable mean<strong>in</strong>g must be deduced from the context.<br />

Inspection after <strong>in</strong>stallation<br />

Inspection <strong>in</strong> order to establish if the <strong>in</strong>stalled<br />

equipment complies with the specified requirements.<br />

Inspection documents A common term <strong>for</strong> documents that control the<br />

manufactur<strong>in</strong>g <strong>in</strong>spections, <strong>in</strong>stallation <strong>in</strong>spections<br />

and ISIs and the <strong>in</strong>spections <strong>in</strong> the plant. The documents<br />

can <strong>in</strong>clude programmes, procedures, <strong>in</strong>-<br />

structions, draw<strong>in</strong>gs etc.<br />

Inspection group Group<strong>in</strong>g <strong>of</strong> the entities to be <strong>in</strong>spected, based on an<br />

evaluation <strong>of</strong> the consequences <strong>of</strong> a damage and the<br />

probability <strong>for</strong> the occurrence <strong>of</strong> such a damage.<br />

Inspection Interval The period <strong>of</strong> time between two consecutive ISIs.<br />

Accord<strong>in</strong>g to the def<strong>in</strong>ition <strong>of</strong> Qualification Defect,<br />

the <strong>in</strong>spection <strong>in</strong>terval may not be longer than the<br />

time it takes <strong>for</strong> a defect to grow from <strong>qualification</strong><br />

defect size to acceptable defect size.<br />

Note however, that if there is no reason to expect<br />

defects to be present (the normal case), or if no defects<br />

are detected <strong>in</strong> an ISI, the follow<strong>in</strong>g <strong>in</strong>spection<br />

<strong>in</strong>terval may be calculated as the time <strong>of</strong> defect<br />

growth from defect target size to acceptable defect<br />

size.<br />

PBM2<br />

KBM, TBM SKIFS<br />

2000:2<br />

KBM SKIFS<br />

2000:2<br />

KBM,<br />

TBM,<br />

PBM1<br />

KBM<br />

PBM2