1930 Cadillac Brochure Front Cover - GM Heritage Center

1930 Cadillac Brochure Front Cover - GM Heritage Center

1930 Cadillac Brochure Front Cover - GM Heritage Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

y the General Motors Research Laboratories, to insure that no vibration<br />

may mar the smooth performance of the <strong>Cadillac</strong> engine.<br />

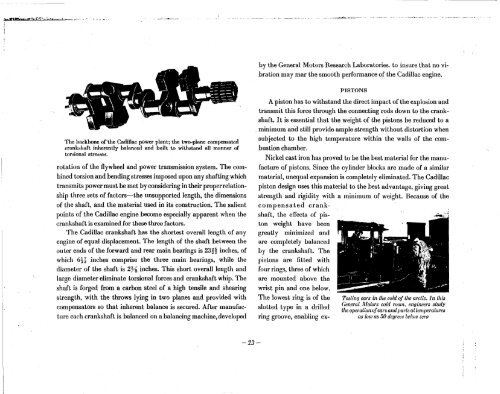

The backbone of'the <strong>Cadillac</strong> power plant; the two-plane compensated<br />

crankshaft inherently balanced and built to withstand all manner of<br />

torsional stresses.<br />

rotation of the flywheel and power transmission system. The combined<br />

torsion and bending stresses imposed upon any shafting which<br />

transmits power must be met by considering in their proper relationship<br />

three sets of factors—the unsupported length, the dimensions<br />

of the shaft, and the material used in its construction. The salient<br />

points of the <strong>Cadillac</strong> engine become especially apparent when the<br />

crankshaft is examined for these three factors.<br />

The <strong>Cadillac</strong> crankshaft has the shortest overall length of any<br />

engine of equal displacement. The length of the shaft between the<br />

outer ends of the forward and rear main bearings is 23 ff inches, of<br />

which 6\l inches comprise the three main bearings, while the<br />

diameter of the shaft is 2¾ inches. This short overall length and<br />

large diameter eliminate torsional forces and crankshaft whip. The<br />

shaft is forged from a carbon steel of a high tensile and shearing<br />

strength, with the throws lying in two planes and provided with<br />

compensators so that inherent balance is secured. After manufacture<br />

each crankshaft is balanced on a balancing machine, developed<br />

PISTONS<br />

A piston has to withstand the direct impact of the explosion and<br />

transmit this force through the connecting rods down to the crankshaft.<br />

It is essential that the weight of the pistons be reduced to a<br />

minimum and still provide ample strength without distortion when<br />

subjected to the high temperature within the walls of the combustion<br />

chamber.<br />

Nickel cast iron has proved to be the best material for the manufacture<br />

of pistons. Since the cylinder blocks are made of a similar<br />

material, unequal expansion is completely eliminated. The <strong>Cadillac</strong><br />

piston design uses this material to the best advantage, giving great<br />

strength and rigidity with a minimum of weight. Because of the<br />

compensated crankshaft,<br />

the effects of piston<br />

weight have been<br />

greatly minimized and<br />

are completely balanced<br />

by the crankshaft. The<br />

pistons are fitted with<br />

four rings, three of which<br />

are mounted above the<br />

wrist pin and one below.<br />

The lowest ring is of the<br />

slotted type in a drilled<br />

ring groove, enabling ex-<br />

[••• ^^59ij<br />

^•"^'.•:i<br />

Testing cars in the cold of the arctic. In this<br />

General Motors cold room, engineers study<br />

llie operation of cars and parts at temperatures<br />

as lotv as 50 degrees below zero<br />

-23