Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

STAGES OF OIL & GAS DEVELOPMENT<br />

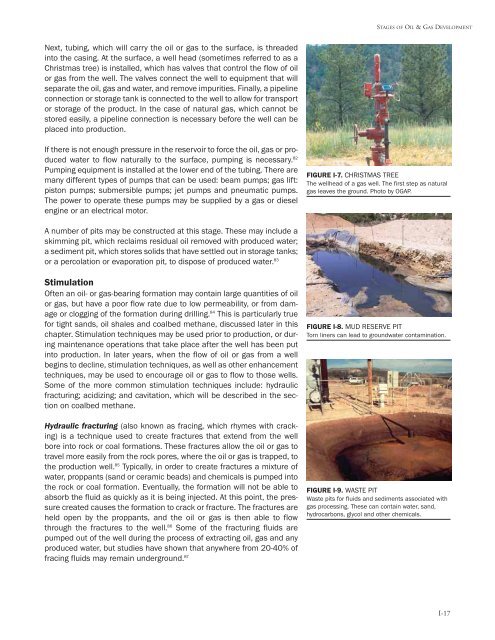

Next, tubing, which will carry the oil or gas to the surface, is threaded<br />

into the casing. At the surface, a well head (sometimes referred to as a<br />

Christmas tree) is installed, which has valves th<strong>at</strong> control the flow of oil<br />

or gas from the well. The valves connect the well to equipment th<strong>at</strong> will<br />

separ<strong>at</strong>e the oil, gas <strong>and</strong> w<strong>at</strong>er, <strong>and</strong> remove impurities. Finally, a pipeline<br />

connection or storage tank is connected to the well to allow for transport<br />

or storage of the product. In the case of n<strong>at</strong>ural gas, which cannot be<br />

stored easily, a pipeline connection is necessary before the well can be<br />

placed into production.<br />

If there is not enough pressure in the reservoir to force the oil, gas or produced<br />

w<strong>at</strong>er to flow n<strong>at</strong>urally to the surface, pumping is necessary. 82<br />

Pumping equipment is installed <strong>at</strong> the lower end of the tubing. There are<br />

many different types of pumps th<strong>at</strong> can be used: beam pumps; gas lift:<br />

piston pumps; submersible pumps; jet pumps <strong>and</strong> pneum<strong>at</strong>ic pumps.<br />

The power to oper<strong>at</strong>e these pumps may be supplied by a gas or diesel<br />

engine or an electrical motor.<br />

FIGURE I-7. CHRISTMAS TREE<br />

The wellhead of a gas well. The first step as n<strong>at</strong>ural<br />

gas leaves the ground. Photo by OGAP.<br />

A number of pits may be constructed <strong>at</strong> this stage. These may include a<br />

skimming pit, which reclaims residual oil removed with produced w<strong>at</strong>er;<br />

a sediment pit, which stores solids th<strong>at</strong> have settled out in storage tanks;<br />

or a percol<strong>at</strong>ion or evapor<strong>at</strong>ion pit, to dispose of produced w<strong>at</strong>er. 83<br />

Stimul<strong>at</strong>ion<br />

Often an oil- or gas-bearing form<strong>at</strong>ion may contain large quantities of oil<br />

or gas, but have a poor flow r<strong>at</strong>e due to low permeability, or from damage<br />

or clogging of the form<strong>at</strong>ion during drilling. 84 This is particularly true<br />

for tight s<strong>and</strong>s, oil shales <strong>and</strong> coalbed methane, discussed l<strong>at</strong>er in this<br />

chapter. Stimul<strong>at</strong>ion techniques may be used prior to production, or during<br />

maintenance oper<strong>at</strong>ions th<strong>at</strong> take place after the well has been put<br />

into production. In l<strong>at</strong>er years, when the flow of oil or gas from a well<br />

begins to decline, stimul<strong>at</strong>ion techniques, as well as other enhancement<br />

techniques, may be used to encourage oil or gas to flow to those wells.<br />

Some of the more common stimul<strong>at</strong>ion techniques include: hydraulic<br />

fracturing; acidizing; <strong>and</strong> cavit<strong>at</strong>ion, which will be described in the section<br />

on coalbed methane.<br />

FIGURE I-8. MUD RESERVE PIT<br />

Torn liners can lead to groundw<strong>at</strong>er contamin<strong>at</strong>ion.<br />

Hydraulic fracturing (also known as fracing, which rhymes with cracking)<br />

is a technique used to cre<strong>at</strong>e fractures th<strong>at</strong> extend from the well<br />

bore into rock or coal form<strong>at</strong>ions. These fractures allow the oil or gas to<br />

travel more easily from the rock pores, where the oil or gas is trapped, to<br />

the production well. 85 Typically, in order to cre<strong>at</strong>e fractures a mixture of<br />

w<strong>at</strong>er, proppants (s<strong>and</strong> or ceramic beads) <strong>and</strong> chemicals is pumped into<br />

the rock or coal form<strong>at</strong>ion. Eventually, the form<strong>at</strong>ion will not be able to<br />

absorb the fluid as quickly as it is being injected. At this point, the pressure<br />

cre<strong>at</strong>ed causes the form<strong>at</strong>ion to crack or fracture. The fractures are<br />

held open by the proppants, <strong>and</strong> the oil or gas is then able to flow<br />

FIGURE I-9. WASTE PIT<br />

Waste pits for fluids <strong>and</strong> sediments associ<strong>at</strong>ed with<br />

gas processing. These can contain w<strong>at</strong>er, s<strong>and</strong>,<br />

hydrocarbons, glycol <strong>and</strong> other chemicals.<br />

through the fractures to the well. 86 Some of the fracturing fluids are<br />

pumped out of the well during the process of extracting oil, gas <strong>and</strong> any<br />

produced w<strong>at</strong>er, but studies have shown th<strong>at</strong> anywhere from 20-40% of<br />

fracing fluids may remain underground. 87 I-17