Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Oil</strong> <strong>and</strong> <strong>Gas</strong> Development <strong>and</strong> Impacts<br />

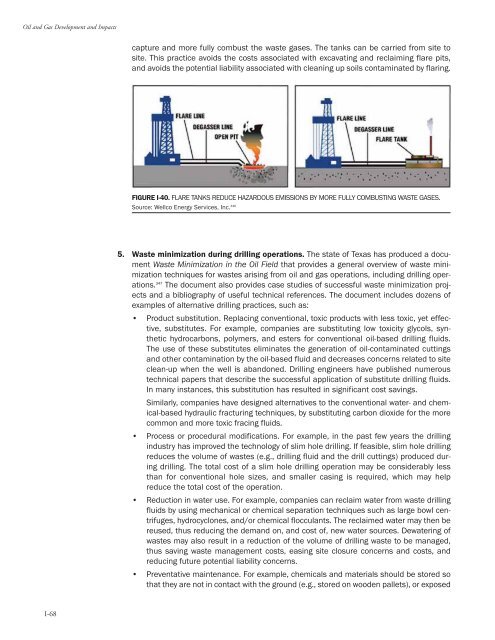

capture <strong>and</strong> more fully combust the waste gases. The tanks can be carried from site to<br />

site. This practice avoids the costs associ<strong>at</strong>ed with excav<strong>at</strong>ing <strong>and</strong> reclaiming flare pits,<br />

<strong>and</strong> avoids the potential liability associ<strong>at</strong>ed with cleaning up soils contamin<strong>at</strong>ed by flaring.<br />

FIGURE I-40. FLARE TANKS REDUCE HAZARDOUS EMISSIONS BY MORE FULLY COMBUSTING WASTE GASES.<br />

Source: Wellco Energy Services, Inc. 346<br />

5. Waste minimiz<strong>at</strong>ion during drilling oper<strong>at</strong>ions. The st<strong>at</strong>e of Texas has produced a document<br />

Waste Minimiz<strong>at</strong>ion in the <strong>Oil</strong> Field th<strong>at</strong> provides a general overview of waste minimiz<strong>at</strong>ion<br />

techniques for wastes arising from oil <strong>and</strong> gas oper<strong>at</strong>ions, including drilling oper<strong>at</strong>ions.<br />

347 The document also provides case studies of successful waste minimiz<strong>at</strong>ion projects<br />

<strong>and</strong> a bibliography of useful technical references. The document includes dozens of<br />

examples of altern<strong>at</strong>ive drilling practices, such as:<br />

• Product substitution. Replacing conventional, toxic products with less toxic, yet effective,<br />

substitutes. For example, companies are substituting low toxicity glycols, synthetic<br />

hydrocarbons, polymers, <strong>and</strong> esters for conventional oil-based drilling fluids.<br />

The use of these substitutes elimin<strong>at</strong>es the gener<strong>at</strong>ion of oil-contamin<strong>at</strong>ed cuttings<br />

<strong>and</strong> other contamin<strong>at</strong>ion by the oil-based fluid <strong>and</strong> decreases concerns rel<strong>at</strong>ed to site<br />

clean-up when the well is ab<strong>and</strong>oned. Drilling engineers have published numerous<br />

technical papers th<strong>at</strong> describe the successful applic<strong>at</strong>ion of substitute drilling fluids.<br />

In many instances, this substitution has resulted in significant cost savings.<br />

Similarly, companies have designed altern<strong>at</strong>ives to the conventional w<strong>at</strong>er- <strong>and</strong> chemical-based<br />

hydraulic fracturing techniques, by substituting carbon dioxide for the more<br />

common <strong>and</strong> more toxic fracing fluids.<br />

• Process or procedural modific<strong>at</strong>ions. For example, in the past few years the drilling<br />

industry has improved the technology of slim hole drilling. If feasible, slim hole drilling<br />

reduces the volume of wastes (e.g., drilling fluid <strong>and</strong> the drill cuttings) produced during<br />

drilling. The total cost of a slim hole drilling oper<strong>at</strong>ion may be considerably less<br />

than for conventional hole sizes, <strong>and</strong> smaller casing is required, which may help<br />

reduce the total cost of the oper<strong>at</strong>ion.<br />

• Reduction in w<strong>at</strong>er use. For example, companies can reclaim w<strong>at</strong>er from waste drilling<br />

fluids by using mechanical or chemical separ<strong>at</strong>ion techniques such as large bowl centrifuges,<br />

hydrocyclones, <strong>and</strong>/or chemical flocculants. The reclaimed w<strong>at</strong>er may then be<br />

reused, thus reducing the dem<strong>and</strong> on, <strong>and</strong> cost of, new w<strong>at</strong>er sources. Dew<strong>at</strong>ering of<br />

wastes may also result in a reduction of the volume of drilling waste to be managed,<br />

thus saving waste management costs, easing site closure concerns <strong>and</strong> costs, <strong>and</strong><br />

reducing future potential liability concerns.<br />

• Prevent<strong>at</strong>ive maintenance. For example, chemicals <strong>and</strong> m<strong>at</strong>erials should be stored so<br />

th<strong>at</strong> they are not in contact with the ground (e.g., stored on wooden pallets), or exposed<br />

I-68