Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

STAGES OF OIL & GAS DEVELOPMENT<br />

to the we<strong>at</strong>her. There should be secondary containment in the case of spills. All drums<br />

<strong>and</strong> containers should be kept closed except when in use. It is very important th<strong>at</strong> all<br />

chemical <strong>and</strong> m<strong>at</strong>erial containers always be properly labeled so th<strong>at</strong> their contents may<br />

be identified <strong>at</strong> any time. Proper storage <strong>and</strong> labeling of containers allows quick <strong>and</strong><br />

easy identific<strong>at</strong>ion <strong>and</strong> classific<strong>at</strong>ion of released chemical or m<strong>at</strong>erial in the event of a<br />

leak or rupture. In some instances, th<strong>at</strong> could save hundreds of dollars in soil sampling<br />

<strong>and</strong> labor<strong>at</strong>ory analysis costs.<br />

• Recycling. For example, the cost of closing a drilling site is increased if waste drilling<br />

fluid in a reserve pit must be dew<strong>at</strong>ered <strong>and</strong>/or stabilized prior to closure. An altern<strong>at</strong>ive<br />

is to recycle or reuse the waste drilling fluid, e.g., in another drilling project. One<br />

company designed a multi-well drilling project where the same drilling fluid was used<br />

for drilling each successive well. The result was significant cost savings <strong>and</strong> gre<strong>at</strong>ly<br />

reduced waste management concerns. Another cost effective altern<strong>at</strong>ive for reuse of<br />

waste drilling fluid is in plugging or spudding of other wells.<br />

ALTERNATIVES USED DURING THE PRODUCTION PHASE<br />

1. Minimizing Surface Disturbance<br />

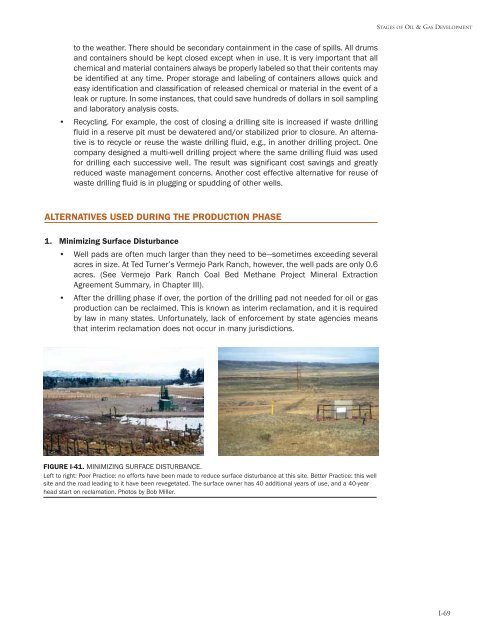

• Well pads are often much larger than they need to be—sometimes exceeding several<br />

acres in size. At Ted Turner’s Vermejo Park Ranch, however, the well pads are only 0.6<br />

acres. (See Vermejo Park Ranch Coal Bed Methane Project Mineral Extraction<br />

Agreement Summary, in Chapter III).<br />

• After the drilling phase if over, the portion of the drilling pad not needed for oil or gas<br />

production can be reclaimed. This is known as interim reclam<strong>at</strong>ion, <strong>and</strong> it is required<br />

by law in many st<strong>at</strong>es. Unfortun<strong>at</strong>ely, lack of enforcement by st<strong>at</strong>e agencies means<br />

th<strong>at</strong> interim reclam<strong>at</strong>ion does not occur in many jurisdictions.<br />

FIGURE I-41. MINIMIZING SURFACE DISTURBANCE.<br />

Left to right: Poor Practice: no efforts have been made to reduce surface disturbance <strong>at</strong> this site. Better Practice: this well<br />

site <strong>and</strong> the road leading to it have been reveget<strong>at</strong>ed. The surface owner has 40 additional years of use, <strong>and</strong> a 40-year<br />

head start on reclam<strong>at</strong>ion. Photos by Bob Miller.<br />

I-69