Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Oil</strong> <strong>and</strong> <strong>Gas</strong> Development <strong>and</strong> Impacts<br />

N<strong>at</strong>ural gas coming directly from a well contains many n<strong>at</strong>ural gas liquids<br />

(NGLs), e.g., ethane, propane, butane, iso-butane, <strong>and</strong> n<strong>at</strong>ural<br />

gasoline. NGLs often have a higher value when sold as separ<strong>at</strong>e products,<br />

making it economical to remove them from the gas stream. The<br />

removal of n<strong>at</strong>ural gas liquids usually takes place in a centralized processing<br />

plant, <strong>and</strong> uses techniques similar to those used to dehydr<strong>at</strong>e<br />

n<strong>at</strong>ural gas. 111<br />

In addition to the processes mentioned above, scrubbers <strong>and</strong> he<strong>at</strong>ers<br />

are installed either <strong>at</strong> or near the wellhead. The scrubbers remove<br />

s<strong>and</strong> <strong>and</strong> other large-particle impurities. The he<strong>at</strong>ers ensure th<strong>at</strong> the<br />

temper<strong>at</strong>ure of the gas does not drop too low <strong>and</strong> form n<strong>at</strong>ural gas<br />

hydr<strong>at</strong>es, which are solid or semi-solid compounds th<strong>at</strong> resemble ice<br />

crystals. Should these hydr<strong>at</strong>es accumul<strong>at</strong>e, they can impede the passage<br />

of n<strong>at</strong>ural gas through valves <strong>and</strong> g<strong>at</strong>hering systems. In addition<br />

to wellhead he<strong>at</strong>ers, small n<strong>at</strong>ural gas-fired he<strong>at</strong>ing units are typically<br />

installed along the g<strong>at</strong>hering pipe wherever it is likely th<strong>at</strong> hydr<strong>at</strong>es<br />

may form. 112<br />

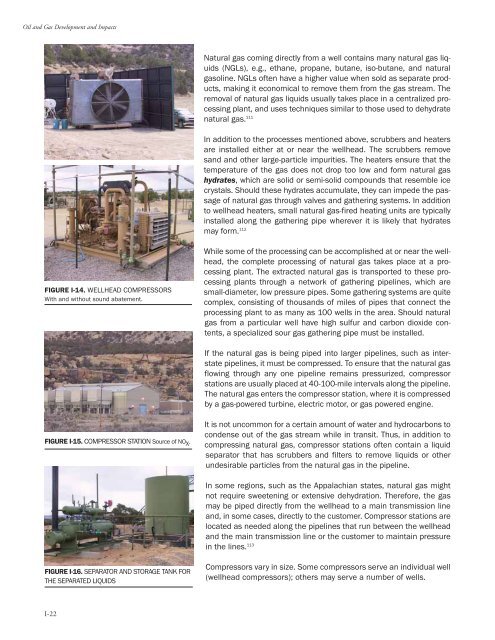

FIGURE I-14. WELLHEAD COMPRESSORS<br />

With <strong>and</strong> without sound ab<strong>at</strong>ement.<br />

While some of the processing can be accomplished <strong>at</strong> or near the wellhead,<br />

the complete processing of n<strong>at</strong>ural gas takes place <strong>at</strong> a processing<br />

plant. The extracted n<strong>at</strong>ural gas is transported to these processing<br />

plants through a network of g<strong>at</strong>hering pipelines, which are<br />

small-diameter, low pressure pipes. Some g<strong>at</strong>hering systems are quite<br />

complex, consisting of thous<strong>and</strong>s of miles of pipes th<strong>at</strong> connect the<br />

processing plant to as many as 100 wells in the area. Should n<strong>at</strong>ural<br />

gas from a particular well have high sulfur <strong>and</strong> carbon dioxide contents,<br />

a specialized sour gas g<strong>at</strong>hering pipe must be installed.<br />

If the n<strong>at</strong>ural gas is being piped into larger pipelines, such as interst<strong>at</strong>e<br />

pipelines, it must be compressed. To ensure th<strong>at</strong> the n<strong>at</strong>ural gas<br />

flowing through any one pipeline remains pressurized, compressor<br />

st<strong>at</strong>ions are usually placed <strong>at</strong> 40-100-mile intervals along the pipeline.<br />

The n<strong>at</strong>ural gas enters the compressor st<strong>at</strong>ion, where it is compressed<br />

by a gas-powered turbine, electric motor, or gas powered engine.<br />

FIGURE I-15. COMPRESSOR STATION Source of NO X .<br />

It is not uncommon for a certain amount of w<strong>at</strong>er <strong>and</strong> hydrocarbons to<br />

condense out of the gas stream while in transit. Thus, in addition to<br />

compressing n<strong>at</strong>ural gas, compressor st<strong>at</strong>ions often contain a liquid<br />

separ<strong>at</strong>or th<strong>at</strong> has scrubbers <strong>and</strong> filters to remove liquids or other<br />

undesirable particles from the n<strong>at</strong>ural gas in the pipeline.<br />

In some regions, such as the Appalachian st<strong>at</strong>es, n<strong>at</strong>ural gas might<br />

not require sweetening or extensive dehydr<strong>at</strong>ion. Therefore, the gas<br />

may be piped directly from the wellhead to a main transmission line<br />

<strong>and</strong>, in some cases, directly to the customer. Compressor st<strong>at</strong>ions are<br />

loc<strong>at</strong>ed as needed along the pipelines th<strong>at</strong> run between the wellhead<br />

<strong>and</strong> the main transmission line or the customer to maintain pressure<br />

in the lines. 113<br />

FIGURE I-16. SEPARATOR AND STORAGE TANK FOR<br />

THE SEPARATED LIQUIDS<br />

Compressors vary in size. Some compressors serve an individual well<br />

(wellhead compressors); others may serve a number of wells.<br />

I-22