Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

Oil and Gas at Your Door? (2005 Edition) - Earthworks

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IMPACTS ASSOCIATED WITH OIL AND GAS<br />

Conserv<strong>at</strong>ion Division has been investig<strong>at</strong>ing contamin<strong>at</strong>ion in two regions where there is oil <strong>and</strong><br />

gas development. Out of 734 cases of soil or groundw<strong>at</strong>er contamin<strong>at</strong>ion st<strong>at</strong>ewide, 444 were<br />

<strong>at</strong> oil or gas field production loc<strong>at</strong>ions. 273<br />

In New Mexico, about half of all explor<strong>at</strong>ion <strong>and</strong> production wastes (other than produced w<strong>at</strong>er <strong>and</strong><br />

drilling muds <strong>and</strong> cuttings) are disposed in pits, about 45% are diverted to oil “reclaimers,” <strong>and</strong><br />

the remainder of the wastes are buried on-site. 274<br />

These disposal methods are typical for the industry. In addition to pit disposal <strong>and</strong> burial, l<strong>and</strong>farming<br />

(the process of spreading waste oil on soil) is a st<strong>and</strong>ard industry practice for disposing<br />

of hydrocarbon wastes. In many jurisdictions, oil companies may use a design<strong>at</strong>ed area for<br />

spreading oil or hydrocarbon-contamin<strong>at</strong>ed soils, as long as the l<strong>and</strong> is not going to be used for<br />

agriculture. 275 L<strong>and</strong>farming may involve the bioremedi<strong>at</strong>ion of the soil, to decrease the levels of<br />

hydrocarbons. To achieve bioremedi<strong>at</strong>ion, hydrocarbon-digesting microbes found n<strong>at</strong>urally in<br />

soil are enhanced with fertilizers <strong>and</strong> moisture to degrade the m<strong>at</strong>erial. The site is tilled periodically<br />

<strong>and</strong> w<strong>at</strong>ered to maintain proper amounts of air <strong>and</strong> moisture. 276<br />

Many oil <strong>and</strong> gas oper<strong>at</strong>ors choose to send hydrocarbon wastes such as tank bottoms to commercial<br />

oil field waste disposal facilities, or reclaimers. The crude oil reclam<strong>at</strong>ion industry recovers<br />

marketable crude oil <strong>and</strong> other hydrocarbons from produced w<strong>at</strong>er, tank bottoms <strong>and</strong> other<br />

oily wastes th<strong>at</strong> are gener<strong>at</strong>ed by the production of oil <strong>and</strong> n<strong>at</strong>ural gas. Marketable crude oil is<br />

recovered from the waste m<strong>at</strong>erials by simple thermal <strong>and</strong>/or physical processes (e.g., he<strong>at</strong> <strong>and</strong><br />

gravity separ<strong>at</strong>ion). As with on-site waste pits, these off-site facilities pose a significant risk to<br />

migr<strong>at</strong>ory birds <strong>and</strong> other wildlife because they use large evapor<strong>at</strong>ion ponds to dispose of <strong>and</strong><br />

tre<strong>at</strong> oil <strong>and</strong> gas wastes. Commercial facilities th<strong>at</strong> dispose of wastew<strong>at</strong>er through deep well<br />

injection generally do not pose a risk to wildlife, but may pose a thre<strong>at</strong> to groundw<strong>at</strong>er<br />

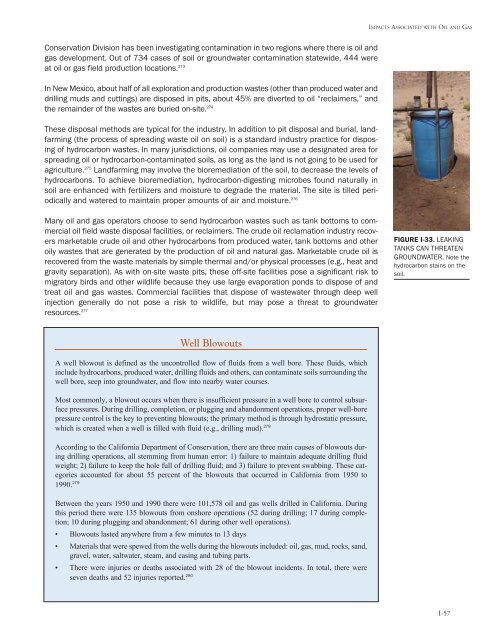

FIGURE I-33. LEAKING<br />

TANKS CAN THREATEN<br />

GROUNDWATER. Note the<br />

hydrocarbon stains on the<br />

soil.<br />

resources. 277 I-57<br />

Well Blowouts<br />

A well blowout is defined as the uncontrolled flow of fluids from a well bore. These fluids, which<br />

include hydrocarbons, produced w<strong>at</strong>er, drilling fluids <strong>and</strong> others, can contamin<strong>at</strong>e soils surrounding the<br />

well bore, seep into groundw<strong>at</strong>er, <strong>and</strong> flow into nearby w<strong>at</strong>er courses.<br />

Most commonly, a blowout occurs when there is insufficient pressure in a well bore to control subsurface<br />

pressures. During drilling, completion, or plugging <strong>and</strong> ab<strong>and</strong>onment oper<strong>at</strong>ions, proper well-bore<br />

pressure control is the key to preventing blowouts; the primary method is through hydrost<strong>at</strong>ic pressure,<br />

which is cre<strong>at</strong>ed when a well is filled with fluid (e.g., drilling mud). 278<br />

According to the California Department of Conserv<strong>at</strong>ion, there are three main causes of blowouts during<br />

drilling oper<strong>at</strong>ions, all stemming from human error: 1) failure to maintain adequ<strong>at</strong>e drilling fluid<br />

weight; 2) failure to keep the hole full of drilling fluid; <strong>and</strong> 3) failure to prevent swabbing. These c<strong>at</strong>egories<br />

accounted for about 55 percent of the blowouts th<strong>at</strong> occurred in California from 1950 to<br />

1990. 279<br />

Between the years 1950 <strong>and</strong> 1990 there were 101,578 oil <strong>and</strong> gas wells drilled in California. During<br />

this period there were 135 blowouts from onshore oper<strong>at</strong>ions (52 during drilling; 17 during completion;<br />

10 during plugging <strong>and</strong> ab<strong>and</strong>onment; 61 during other well oper<strong>at</strong>ions).<br />

• Blowouts lasted anywhere from a few minutes to 13 days<br />

• M<strong>at</strong>erials th<strong>at</strong> were spewed from the wells during the blowouts included: oil, gas, mud, rocks, s<strong>and</strong>,<br />

gravel, w<strong>at</strong>er, saltw<strong>at</strong>er, steam, <strong>and</strong> casing <strong>and</strong> tubing parts.<br />

• There were injuries or de<strong>at</strong>hs associ<strong>at</strong>ed with 28 of the blowout incidents. In total, there were<br />

seven de<strong>at</strong>hs <strong>and</strong> 52 injuries reported. 280