LM 286 EN 30012013.book - Oy LAIMU Ab

LM 286 EN 30012013.book - Oy LAIMU Ab

LM 286 EN 30012013.book - Oy LAIMU Ab

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>LM</strong> <strong>286</strong><br />

User manual<br />

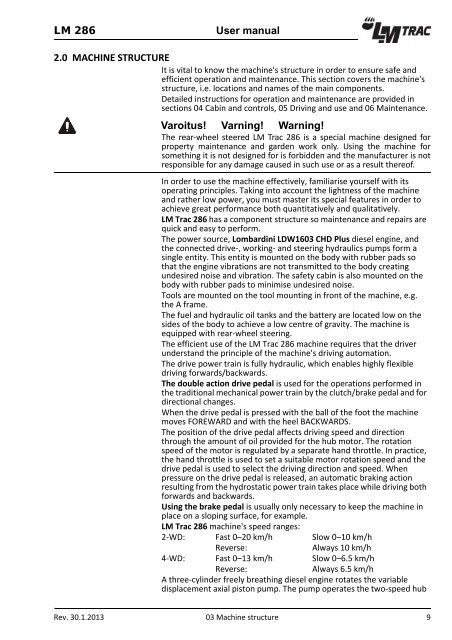

2.0 MACHINE STRUCTURE<br />

It is vital to know the machine's structure in order to ensure safe and<br />

efficient operation and maintenance. This section covers the machine's<br />

structure, i.e. locations and names of the main components.<br />

Detailed instructions for operation and maintenance are provided in<br />

sections 04 Cabin and controls, 05 Driving and use and 06 Maintenance.<br />

Varoitus! Varning! Warning!<br />

The rear‐wheel steered <strong>LM</strong> Trac <strong>286</strong> is a special machine designed for<br />

property maintenance and garden work only. Using the machine for<br />

something it is not designed for is forbidden and the manufacturer is not<br />

responsible for any damage caused in such use or as a result thereof.<br />

In order to use the machine effectively, familiarise yourself with its<br />

operating principles. Taking into account the lightness of the machine<br />

and rather low power, you must master its special features in order to<br />

achieve great performance both quantitatively and qualitatively.<br />

<strong>LM</strong> Trac <strong>286</strong> has a component structure so maintenance and repairs are<br />

quick and easy to perform.<br />

The power source, Lombardini LDW1603 CHD Plus diesel engine, and<br />

the connected drive‐, working‐ and steering hydraulics pumps form a<br />

single entity. This entity is mounted on the body with rubber pads so<br />

that the engine vibrations are not transmitted to the body creating<br />

undesired noise and vibration. The safety cabin is also mounted on the<br />

body with rubber pads to minimise undesired noise.<br />

Tools are mounted on the tool mounting in front of the machine, e.g.<br />

the A frame.<br />

The fuel and hydraulic oil tanks and the battery are located low on the<br />

sides of the body to achieve a low centre of gravity. The machine is<br />

equipped with rear‐wheel steering.<br />

The efficient use of the <strong>LM</strong> Trac <strong>286</strong> machine requires that the driver<br />

understand the principle of the machine's driving automation.<br />

The drive power train is fully hydraulic, which enables highly flexible<br />

driving forwards/backwards.<br />

The double action drive pedal is used for the operations performed in<br />

the traditional mechanical power train by the clutch/brake pedal and for<br />

directional changes.<br />

When the drive pedal is pressed with the ball of the foot the machine<br />

moves FOREWARD and with the heel BACKWARDS.<br />

The position of the drive pedal affects driving speed and direction<br />

through the amount of oil provided for the hub motor. The rotation<br />

speed of the motor is regulated by a separate hand throttle. In practice,<br />

the hand throttle is used to set a suitable motor rotation speed and the<br />

drive pedal is used to select the driving direction and speed. When<br />

pressure on the drive pedal is released, an automatic braking action<br />

resulting from the hydrostatic power train takes place while driving both<br />

forwards and backwards.<br />

Using the brake pedal is usually only necessary to keep the machine in<br />

place on a sloping surface, for example.<br />

<strong>LM</strong> Trac <strong>286</strong> machine's speed ranges:<br />

2‐WD: Fast 0–20 km/h Slow 0–10 km/h<br />

Reverse:<br />

Always 10 km/h<br />

4‐WD: Fast 0–13 km/h Slow 0–6.5 km/h<br />

Reverse:<br />

Always 6.5 km/h<br />

A three‐cylinder freely breathing diesel engine rotates the variable<br />

displacement axial piston pump. The pump operates the two‐speed hub<br />

Rev. 30.1.2013 03 Machine structure 9