- Page 1 and 2:

ST1 B T2 A T1 C * B T3 page 0 ST3 T

- Page 3 and 4:

page i 1.1 TODO LIST 1.3 2. PROGRAM

- Page 5 and 6:

page iii 7.5 ASSIGNMENT PROBLEMS 7.

- Page 7 and 8:

page v 14.3 PROGRAMS 14.3 14.4 VARI

- Page 9 and 10: page vii 20.4 PRACTICE PROBLEMS 20.

- Page 11 and 12: page ix 25.2 CONTROL OF LOGICAL ACT

- Page 13 and 14: page xi 30. HUMAN MACHINE INTERFACE

- Page 15 and 16: page xiii 35.16 P 35.21 35.17 Q 35.

- Page 17 and 18: plc wiring - 1.2 • Linear - Can b

- Page 19 and 20: plc wiring - 1.4 - update serial IO

- Page 21 and 22: plc wiring - 2.2 logic diagrams was

- Page 23 and 24: plc wiring - 2.4 115VAC wall plug r

- Page 25 and 26: plc wiring - 2.6 A B B Note: When A

- Page 27 and 28: plc wiring - 2.8 number there. The

- Page 29 and 30: plc wiring - 2.10 i := 0; REPEAT i

- Page 31 and 32: plc wiring - 2.12 x Normally open,

- Page 33 and 34: plc wiring - 2.14 Solution: There a

- Page 35 and 36: plc wiring - 2.16 4. Less expensive

- Page 37 and 38: plc wiring - 3.2 allows the PLC to

- Page 39 and 40: plc wiring - 3.4 5 Vdc (TTL) 200-24

- Page 41 and 42: plc wiring - 3.6 Remember - Don’t

- Page 43 and 44: plc wiring - 3.8 As with input modu

- Page 45 and 46: plc wiring - 3.10 accidentally conn

- Page 47 and 48: plc wiring - 3.12 could have many d

- Page 49 and 50: plc wiring - 3.14 ing large power l

- Page 51 and 52: plc wiring - 3.16 The lines of thes

- Page 53 and 54: plc wiring - 3.18 In the wiring dia

- Page 55 and 56: plc wiring - 3.20 temperature norma

- Page 57 and 58: plc wiring - 3.22 3.6 SUMMARY • P

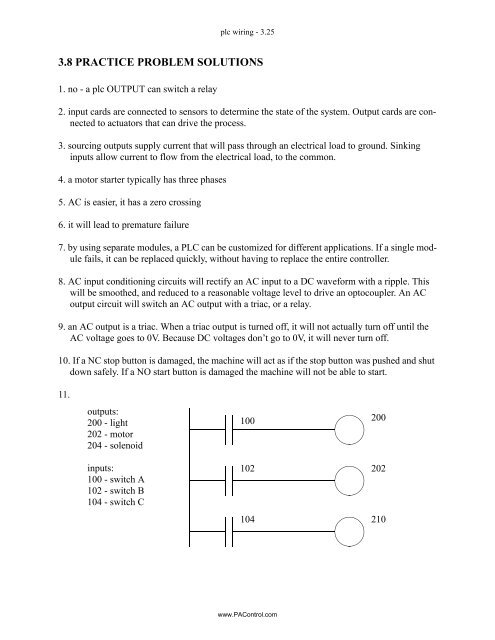

- Page 59: plc wiring - 3.24 show all necessar

- Page 63 and 64: plc wiring - 3.28 16. relay output

- Page 65 and 66: discrete sensors - 4.1 4. LOGICAL S

- Page 67 and 68: discrete sensors - 4.3 4.2.2 Transi

- Page 69 and 70: discrete sensors - 4.5 value, and t

- Page 71 and 72: discrete sensors - 4.7 PLC Input Ca

- Page 73 and 74: discrete sensors - 4.9 PLC Input Ca

- Page 75 and 76: discrete sensors - 4.11 4.3 PRESENC

- Page 77 and 78: discrete sensors - 4.13 components,

- Page 79 and 80: discrete sensors - 4.15 emitter obj

- Page 81 and 82: discrete sensors - 4.17 emitter ref

- Page 83 and 84: discrete sensors - 4.19 ure 4.22. T

- Page 85 and 86: discrete sensors - 4.21 electrode m

- Page 87 and 88: discrete sensors - 4.23 Material Co

- Page 89 and 90: discrete sensors - 4.25 shielded un

- Page 91 and 92: discrete sensors - 4.27 4.5 PRACTIC

- Page 93 and 94: discrete sensors - 4.29 in:2.I.Data

- Page 95 and 96: discrete sensors - 4.31 4. 24Vdc ou

- Page 97 and 98: discrete sensors - 4.33 6. 00 01 02

- Page 99 and 100: discrete sensors - 4.35 8. + power

- Page 101 and 102: discrete sensors - 4.37 4. a) Show

- Page 103 and 104: discrete actuators - 5.2 As mention

- Page 105 and 106: discrete actuators - 5.4 Two way, t

- Page 107 and 108: discrete actuators - 5.6 single act

- Page 109 and 110: discrete actuators - 5.8 Figure 5.6

- Page 111 and 112:

discrete actuators - 5.10 5.8 OTHER

- Page 113 and 114:

discrete actuators - 5.12 3. ADD SO

- Page 115 and 116:

plc boolean - 6.2 Note: By conventi

- Page 117 and 118:

plc boolean - 6.4 Idempotent A + A

- Page 119 and 120:

plc boolean - 6.6 6.3 LOGIC DESIGN

- Page 121 and 122:

plc boolean - 6.8 Ladder Logic for

- Page 123 and 124:

plc boolean - 6.10 der logic there

- Page 125 and 126:

plc boolean - 6.12 A = B⋅ C⋅ (

- Page 127 and 128:

plc boolean - 6.14 A+ CA = A+ C pro

- Page 129 and 130:

plc boolean - 6.16 D1 D2 D3 multipl

- Page 131 and 132:

plc boolean - 6.18 Solution: D = A+

- Page 133 and 134:

plc boolean - 6.20 The inputs and o

- Page 135 and 136:

plc boolean - 6.22 A = ( S⋅ M⋅

- Page 137 and 138:

plc boolean - 6.24 • Truth tables

- Page 139 and 140:

plc boolean - 6.26 b) Simplify the

- Page 141 and 142:

plc boolean - 6.28 2. A B D C 3. B

- Page 143 and 144:

plc boolean - 6.30 9. a) ( A+ B)

- Page 145 and 146:

plc boolean - 6.32 A B C B C D C A

- Page 147 and 148:

plc boolean - 6.34 17. D A Y 18. CA

- Page 149 and 150:

plc boolean - 6.36 c) A X B A C C A

- Page 151 and 152:

plc boolean - 6.38 2. Simplify the

- Page 153 and 154:

plc karnaugh - 7.1 7. KARNAUGH MAPS

- Page 155 and 156:

plc karnaugh - 7.3 expression. The

- Page 157 and 158:

plc karnaugh - 7.5 7.3 PRACTICE PRO

- Page 159 and 160:

plc karnaugh - 7.7 5. Examine the t

- Page 161 and 162:

plc karnaugh - 7.9 Boolean equation

- Page 163 and 164:

plc karnaugh - 7.11 13. Consider th

- Page 165 and 166:

plc karnaugh - 7.13 5. 00 FG 01 11

- Page 167 and 168:

plc karnaugh - 7.15 9. CD AB AB A B

- Page 169 and 170:

plc karnaugh - 7.17 12. DA + ACD AB

- Page 171 and 172:

plc karnaugh - 7.19 4. Convert the

- Page 173 and 174:

plc operation - 8.2 inputs and outp

- Page 175 and 176:

plc operation - 8.4 input scan take

- Page 177 and 178:

plc operation - 8.6 8.3 PLC STATUS

- Page 179 and 180:

plc operation - 8.8 outputs are not

- Page 181 and 182:

plc timers - 9.1 9. LATCHES, TIMERS

- Page 183 and 184:

plc timers - 9.3 The operation of t

- Page 185 and 186:

plc timers - 9.5 I/0 O/0 I/0 O/1 L

- Page 187 and 188:

plc timers - 9.7 oven has been turn

- Page 189 and 190:

plc timers - 9.9 The timing diagram

- Page 191 and 192:

plc timers - 9.11 go TON t_1 delay

- Page 193 and 194:

plc timers - 9.13 Start Stop Auto A

- Page 195 and 196:

plc timers - 9.15 A CTU Counter exa

- Page 197 and 198:

plc timers - 9.17 The program in Fi

- Page 199 and 200:

plc timers - 9.19 9.6 INTERNAL BITS

- Page 201 and 202:

plc timers - 9.21 Solution: A TON P

- Page 203 and 204:

plc timers - 9.23 Solution: Motor S

- Page 205 and 206:

plc timers - 9.25 Solution: Go Stop

- Page 207 and 208:

plc timers - 9.27 Solution: TS1 LS1

- Page 209 and 210:

plc timers - 9.29 8. Complete the t

- Page 211 and 212:

plc timers - 9.31 17. Design a conv

- Page 213 and 214:

plc timers - 9.33 7. A RTF Timer t

- Page 215 and 216:

plc timers - 9.35 9. input TON RTO

- Page 217 and 218:

plc timers - 9.37 14. A delay.DN TO

- Page 219 and 220:

plc timers - 9.39 16. left_button T

- Page 221 and 222:

plc timers - 9.41 18. A T4:0/TT C5:

- Page 223 and 224:

plc timers - 9.43 22. GIVE SOLUTION

- Page 225 and 226:

plc timers - 9.45 3. Explain what w

- Page 227 and 228:

plc design - 10.2 Most control syst

- Page 229 and 230:

plc design - 10.4 Description: Step

- Page 231 and 232:

plc design - 10.6 step4 bottom LS s

- Page 233 and 234:

plc design - 10.8 Description: A ha

- Page 235 and 236:

plc design - 10.10 3. The first wra

- Page 237 and 238:

plc design - 10.12 3. (for both sol

- Page 239 and 240:

plc design - 10.14 (with latches fi

- Page 241 and 242:

plc design - 10.16 a) Start in an i

- Page 243 and 244:

plc flowchart - 11.1 11. FLOWCHART

- Page 245 and 246:

plc flowchart - 11.3 START Open out

- Page 247 and 248:

plc flowchart - 11.5 STEP 1: Add la

- Page 249 and 250:

plc flowchart - 11.7 STEP 2: Write

- Page 251 and 252:

plc flowchart - 11.9 F2 start MCR U

- Page 253 and 254:

plc flowchart - 11.11 F6 MCR L outl

- Page 255 and 256:

plc flowchart - 11.13 FS F1 F6 T1 T

- Page 257 and 258:

plc flowchart - 11.15 11.4 SUMMARY

- Page 259 and 260:

plc flowchart - 11.17 2. Start Get

- Page 261 and 262:

plc flowchart - 11.19 F3 gas can fu

- Page 263 and 264:

plc flowchart - 11.21 first scan L

- Page 265 and 266:

plc flowchart - 11.23 ST3 button re

- Page 267 and 268:

plc flowchart - 11.25 ST8 button re

- Page 269 and 270:

plc flowchart - 11.27 3. A welding

- Page 271 and 272:

plc states - 12.1 12. STATE BASED D

- Page 273 and 274:

plc states - 12.3 be active while c

- Page 275 and 276:

plc states - 12.5 Red Yellow Green

- Page 277 and 278:

plc states - 12.7 Step 2: Define St

- Page 279 and 280:

plc states - 12.9 RESET THE STATES

- Page 281 and 282:

plc states - 12.11 FIRST STATE WAIT

- Page 283 and 284:

plc states - 12.13 FOURTH STATE WAI

- Page 285 and 286:

plc states - 12.15 first scan L STB

- Page 287 and 288:

plc states - 12.17 Informally, Stat

- Page 289 and 290:

plc states - 12.19 Now, simplify th

- Page 291 and 292:

plc states - 12.21 OUTPUT LOGIC FOR

- Page 293 and 294:

plc states - 12.23 Each of the alte

- Page 295 and 296:

plc states - 12.25 A state diagram

- Page 297 and 298:

plc states - 12.27 CALCULATE STATE

- Page 299 and 300:

plc states - 12.29 STA T5 B T4 D ST

- Page 301 and 302:

plc states - 12.31 4. Given the fol

- Page 303 and 304:

plc states - 12.33 24 V AC Power Su

- Page 305 and 306:

plc states - 12.35 3. T1 T2 = ST1

- Page 307 and 308:

plc states - 12.37 5. TA TB TC TD T

- Page 309 and 310:

plc states - 12.39 first scan MCR L

- Page 311 and 312:

plc states - 12.41 state 3 MCR rese

- Page 313 and 314:

plc states - 12.43 FS L state_1 U s

- Page 315 and 316:

plc states - 12.45 state_4 MCR remo

- Page 317 and 318:

plc states - 12.47 ST1 remote T1 bu

- Page 319 and 320:

plc states - 12.49 12.5 ASSIGNMENT

- Page 321 and 322:

plc states - 12.51 6. Implement the

- Page 323 and 324:

plc states - 12.53 using an equatio

- Page 325 and 326:

plc states - 12.55 INPUTS I/1 - sta

- Page 327 and 328:

plc numbers - 13.2 decimal binary o

- Page 329 and 330:

plc numbers - 13.4 start with decim

- Page 331 and 332:

plc numbers - 13.6 There are three

- Page 333 and 334:

plc numbers - 13.8 decimal binary b

- Page 335 and 336:

plc numbers - 13.10 13.2.2 Other Ba

- Page 337 and 338:

plc numbers - 13.12 Figure 13.17 AS

- Page 339 and 340:

plc numbers - 13.14 An example of a

- Page 341 and 342:

plc numbers - 13.16 DATA 124 43 255

- Page 343 and 344:

plc numbers - 13.18 a) from base 10

- Page 345 and 346:

plc numbers - 13.20 17. Do the foll

- Page 347 and 348:

plc numbers - 13.22 14. octal binar

- Page 349 and 350:

plc memory - 14.1 14. PLC MEMORY To

- Page 351 and 352:

plc memory - 14.3 14.3 PROGRAMS The

- Page 353 and 354:

plc memory - 14.5 8 - an integer 8.

- Page 355 and 356:

plc memory - 14.7 CU - count up bit

- Page 357 and 358:

plc memory - 14.9 Immediately acces

- Page 359 and 360:

plc memory - 14.11 A selected list

- Page 361 and 362:

plc memory - 14.13 onds after it ha

- Page 363 and 364:

plc memory - 14.15 10. first scan R

- Page 365 and 366:

plc basic functions - 15.2 Combinat

- Page 367 and 368:

plc basic functions - 15.4 A MOV So

- Page 369 and 370:

plc basic functions - 15.6 store th

- Page 371 and 372:

plc basic functions - 15.8 ACS(valu

- Page 373 and 374:

plc basic functions - 15.10 go CPT

- Page 375 and 376:

plc basic functions - 15.12 15.2.4.

- Page 377 and 378:

plc basic functions - 15.14 copy an

- Page 379 and 380:

plc basic functions - 15.16 EQU A B

- Page 381 and 382:

plc basic functions - 15.18 CMP exp

- Page 383 and 384:

plc basic functions - 15.20 Figure

- Page 385 and 386:

plc basic functions - 15.22 after a

- Page 387 and 388:

plc basic functions - 15.24 As desi

- Page 389 and 390:

plc basic functions - 15.26 • Val

- Page 391 and 392:

plc basic functions - 15.28 15.7 PR

- Page 393 and 394:

plc basic functions - 15.30 5. addr

- Page 395 and 396:

plc basic functions - 15.32 S2 part

- Page 397 and 398:

plc basic functions - 15.34 11. AND

- Page 399 and 400:

plc advanced functions - 16.1 16. A

- Page 401 and 402:

plc advanced functions - 16.3 Arith

- Page 403 and 404:

plc advanced functions - 16.5 A FFL

- Page 405 and 406:

plc advanced functions - 16.7 A SQO

- Page 407 and 408:

plc advanced functions - 16.9 A B C

- Page 409 and 410:

plc advanced functions - 16.11 Main

- Page 411 and 412:

plc advanced functions - 16.13 A B

- Page 413 and 414:

plc advanced functions - 16.15 Main

- Page 415 and 416:

plc advanced functions - 16.17 A X

- Page 417 and 418:

plc advanced functions - 16.19 e.g.

- Page 419 and 420:

plc advanced functions - 16.21 S:FS

- Page 421 and 422:

plc advanced functions - 16.23 STA

- Page 423 and 424:

plc advanced functions - 16.25 16.6

- Page 425 and 426:

plc advanced functions - 16.27 4. W

- Page 427 and 428:

plc advanced functions - 16.29 b[0]

- Page 429 and 430:

plc advanced functions - 16.31 3. a

- Page 431 and 432:

plc advanced functions - 16.33 S3 S

- Page 433 and 434:

plc advanced functions - 16.35 10.

- Page 435 and 436:

plc advanced functions - 16.37 16.1

- Page 437 and 438:

plc iec61131 - 17.1 17. OPEN CONTRO

- Page 439 and 440:

plc iec61131 - 17.3 Name Type Bits

- Page 441 and 442:

plc iec61131 - 17.5 technique.) i)

- Page 443 and 444:

plc il - 18.2 I:000/00 I:000/01 O:0

- Page 445 and 446:

plc il - 18.4 Operator Modifiers Da

- Page 447 and 448:

plc il - 18.6 mally using the MPS,

- Page 449 and 450:

plc il - 18.8 value. I:001/0 TON Ti

- Page 451 and 452:

plc il - 18.10 • The Allen Bradle

- Page 453 and 454:

plc st - 19.2 PROGRAM main VAR i :

- Page 455 and 456:

plc st - 19.4 When defining variabl

- Page 457 and 458:

plc st - 19.6 Character strings def

- Page 459 and 460:

plc st - 19.8 AND(A,B) OR(A,B) XOR(

- Page 461 and 462:

plc st - 19.10 The example in Figur

- Page 463 and 464:

plc st - 19.12 Function ABS(A); ACO

- Page 465 and 466:

plc st - 19.14 .... D := TEST(1.3,

- Page 467 and 468:

plc st - 19.16 19.4 SUMMARY • Str

- Page 469 and 470:

plc sfc - 20.1 20. SEQUENTIAL FUNCT

- Page 471 and 472:

plc sfc - 20.3 selection branch - a

- Page 473 and 474:

plc sfc - 20.5 press will then retr

- Page 475 and 476:

plc sfc - 20.7 first scan INITIALIZ

- Page 477 and 478:

plc sfc - 20.9 transition 5 top lim

- Page 479 and 480:

plc sfc - 20.11 step 6 U step 6 L t

- Page 481 and 482:

plc sfc - 20.13 Program 3 (for step

- Page 483 and 484:

plc sfc - 20.15 ST2 TR8 ST2 TR13 FS

- Page 485 and 486:

plc sfc - 20.17 20.4 PRACTICE PROBL

- Page 487 and 488:

plc sfc - 20.19 2. Start EW crosswa

- Page 489 and 490:

plc sfc - 20.21 4. step 1 step 2 T1

- Page 491 and 492:

plc sfc - 20.23 T1 remote L step 3

- Page 493 and 494:

plc sfc - 20.25 step 1 step 2 step

- Page 495 and 496:

plc fb - 21.2 A FBD program is cons

- Page 497 and 498:

plc fb - 21.4 Figure 21.6 shows a d

- Page 499 and 500:

plc analog - 22.1 22. ANALOG INPUTS

- Page 501 and 502:

plc analog - 22.3 A more realistic

- Page 503 and 504:

plc analog - 22.5 R = 2 N = R max -

- Page 505 and 506:

plc analog - 22.7 Figure 22.6 Low S

- Page 507 and 508:

plc analog - 22.9 ASIDE: This devic

- Page 509 and 510:

plc analog - 22.11 (Note: each type

- Page 511 and 512:

plc analog - 22.13 important if the

- Page 513 and 514:

plc analog - 22.15 Given, N = 8, R

- Page 515 and 516:

plc analog - 22.17 tion will change

- Page 517 and 518:

plc analog - 22.19 A t V eff = A A

- Page 519 and 520:

plc analog - 22.21 flow. The resist

- Page 521 and 522:

plc analog - 22.23 • Analog shiel

- Page 523 and 524:

plc analog - 22.25 5. A card with a

- Page 525 and 526:

plc analog - 22.27 7. A SIN Source

- Page 527 and 528:

plc analog - 22.29 22.8 ASSIGNMENT

- Page 529 and 530:

continuous sensors - 23.2 terized w

- Page 531 and 532:

continuous sensors - 23.4 θ max θ

- Page 533 and 534:

continuous sensors - 23.6 sensors r

- Page 535 and 536:

continuous sensors - 23.8 Normally

- Page 537 and 538:

continuous sensors - 23.10 A rod dr

- Page 539 and 540:

continuous sensors - 23.12 on off o

- Page 541 and 542:

continuous sensors - 23.14 Sealant

- Page 543 and 544:

continuous sensors - 23.16 After th

- Page 545 and 546:

continuous sensors - 23.18 stress d

- Page 547 and 548:

continuous sensors - 23.20 23.2.5 L

- Page 549 and 550:

continuous sensors - 23.22 These se

- Page 551 and 552:

continuous sensors - 23.24 result i

- Page 553 and 554:

continuous sensors - 23.26 very hig

- Page 555 and 556:

continuous sensors - 23.28 mV 80 E

- Page 557 and 558:

continuous sensors - 23.30 Thermist

- Page 559 and 560:

continuous sensors - 23.32 23.2.9 O

- Page 561 and 562:

continuous sensors - 23.34 The circ

- Page 563 and 564:

continuous sensors - 23.36 put is p

- Page 565 and 566:

continuous sensors - 23.38 ratio. I

- Page 567 and 568:

continuous sensors - 23.40 10. enco

- Page 569 and 570:

continuous actuators - 24.1 24. CON

- Page 571 and 572:

continuous actuators - 24.3 command

- Page 573 and 574:

continuous actuators - 24.5 wear, w

- Page 575 and 576:

continuous actuators - 24.7 ASIDE:

- Page 577 and 578:

continuous actuators - 24.9 L2 L1 L

- Page 579 and 580:

continuous actuators - 24.11 torque

- Page 581 and 582:

continuous actuators - 24.13 • Si

- Page 583 and 584:

continuous actuators - 24.15 runnin

- Page 585 and 586:

continuous actuators - 24.17 torque

- Page 587 and 588:

continuous actuators - 24.19 torque

- Page 589 and 590:

continuous actuators - 24.21 cally

- Page 591 and 592:

continuous actuators - 24.23 e f =

- Page 593 and 594:

continuous actuators - 24.25 24.5 S

- Page 595 and 596:

continuous actuators - 24.27 a) (an

- Page 597 and 598:

plc pid - 25.2 valve a) Water Tank

- Page 599 and 600:

plc pid - 25.4 to a process, and tu

- Page 601 and 602:

plc pid - 25.6 θ neural desired +

- Page 603 and 604:

plc pid - 25.8 next two sections de

- Page 605 and 606:

plc pid - 25.10 Figure 25.10 A Comb

- Page 607 and 608:

plc pid - 25.12 25.3.4 PID Control

- Page 609 and 610:

plc pid - 25.14 PID Control Block:

- Page 611 and 612:

plc pid - 25.16 S2:1/15 - first sca

- Page 613 and 614:

plc pid - 25.18 SOLUTION Analog Inp

- Page 615 and 616:

plc pid - 25.20 BT9:0/DN BT9:2/EN B

- Page 617 and 618:

plc pid - 25.22 25.7 PRACTICE PROBL

- Page 619 and 620:

plc pid - 25.24 7. S2:1/15 - first

- Page 621 and 622:

plc pid - 25.26 25.8 ASSIGNMENT PRO

- Page 623 and 624:

plc fuzzy - 26.1 26. FUZZY LOGIC T

- Page 625 and 626:

plc fuzzy - 26.3 1. If (bucket is f

- Page 627 and 628:

plc fuzzy - 26.5 1. If v error is L

- Page 629 and 630:

plc fuzzy - 26.7 final motor contro

- Page 631 and 632:

plc fuzzy - 26.9 response will be s

- Page 633 and 634:

plc serial - 27.2 An example of a n

- Page 635 and 636:

plc serial - 27.4 A typical data by

- Page 637 and 638:

plc serial - 27.6 Modem Computer co

- Page 639 and 640:

plc serial - 27.8 RI - (ring indica

- Page 641 and 642:

plc serial - 27.10 ABL(channel, con

- Page 643 and 644:

plc serial - 27.12 ACI String ST9:1

- Page 645 and 646:

plc serial - 27.14 on many new inst

- Page 647 and 648:

plc serial - 27.16 5. Write a progr

- Page 649 and 650:

plc serial - 27.18 5. MOV Source F8

- Page 651 and 652:

plc network - 28.1 28. NETWORKING

- Page 653 and 654:

plc network - 28.3 ... R Repeater R

- Page 655 and 656:

plc network - 28.5 that syntax, for

- Page 657 and 658:

plc network - 28.7 28.1.4 Control N

- Page 659 and 660:

plc network - 28.9 • Data packet

- Page 661 and 662:

plc network - 28.11 MG9:0/EN MSG Se

- Page 663 and 664:

plc network - 28.13 1 bit 11 bits 1

- Page 665 and 666:

plc network - 28.15 46 to 1500 byte

- Page 667 and 668:

plc network - 28.17 1 byte 1 byte D

- Page 669 and 670:

plc network - 28.19 CMD 00 01 02 05

- Page 671 and 672:

plc network - 28.21 Table 1: Networ

- Page 673 and 674:

plc network - 28.23 Figure 28.17 A

- Page 675 and 676:

plc network - 28.25 2. MG9:0/EN MG9

- Page 677 and 678:

plc network - 28.27 b) MG9:0/EN MSG

- Page 679 and 680:

plc network - 28.29 to advance a he

- Page 681 and 682:

plc internet - 29.2 Aside: Open a D

- Page 683 and 684:

plc internet - 29.4 SMTP (Simple Ma

- Page 685 and 686:

plc internet - 29.6 Aside: While lo

- Page 687 and 688:

plc internet - 29.8 • A client do

- Page 689 and 690:

plc internet - 29.10 Windows machin

- Page 691 and 692:

plc hmi - 30.1 30. HUMAN MACHINE IN

- Page 693 and 694:

plc hmi - 30.3 1. Who needs what in

- Page 695 and 696:

plc electrical - 31.1 31. ELECTRICA

- Page 697 and 698:

plc electrical - 31.3 terminals pow

- Page 699 and 700:

plc electrical - 31.5 L1 L2 L3 star

- Page 701 and 702:

plc electrical - 31.7 L1 L2 L3 M M

- Page 703 and 704:

plc electrical - 31.9 31.2.2 Ground

- Page 705 and 706:

plc electrical - 31.11 Note: Always

- Page 707 and 708:

plc electrical - 31.13 31.2.4 Suppr

- Page 709 and 710:

plc electrical - 31.15 Dirt - Dust

- Page 711 and 712:

plc electrical - 31.17 more sensiti

- Page 713 and 714:

plc electrical - 31.19 • Use NO b

- Page 715 and 716:

plc electrical - 31.21 4. Why are n

- Page 717 and 718:

plc software - 32.2 Sabotage - For

- Page 719 and 720:

plc software - 32.4 provides good t

- Page 721 and 722:

plc software - 32.6 Table 1: ANSI/I

- Page 723 and 724:

plc software - 32.8 orifice plate m

- Page 725 and 726:

plc software - 32.10 Each block in

- Page 727 and 728:

plc software - 32.12 2. A basic mod

- Page 729 and 730:

plc software - 32.14 Project Notes

- Page 731 and 732:

plc software - 32.16 Application No

- Page 733 and 734:

plc software - 32.18 Internal Locat

- Page 735 and 736:

plc software - 32.20 These design s

- Page 737 and 738:

plc software - 32.22 ures to the to

- Page 739 and 740:

plc software - 32.24 2. When should

- Page 741 and 742:

plc selection - 33.2 • Determine

- Page 743 and 744:

plc selection - 33.4 PLC MEMORY TIM

- Page 745 and 746:

plc selection - 33.6 Typical values

- Page 747 and 748:

plc selection - 33.8 ized programmi

- Page 749 and 750:

plc selection - 33.10 33.4 PRACTICE

- Page 751 and 752:

plc function ref - 34.2 IIN, IOT -

- Page 753 and 754:

plc function ref - 34.4 MCR - Maste

- Page 755 and 756:

plc function ref - 34.6 CTD - CounT

- Page 757 and 758:

plc function ref - 34.8 TOF - Timer

- Page 759 and 760:

plc function ref - 34.10 RTO - Rete

- Page 761 and 762:

plc function ref - 34.12 FBC, DDT -

- Page 763 and 764:

plc function ref - 34.14 34.1.5 Cal

- Page 765 and 766:

plc function ref - 34.16 AVE, STD -

- Page 767 and 768:

plc function ref - 34.18 FRD, TOD,

- Page 769 and 770:

plc function ref - 34.20 34.1.6 Log

- Page 771 and 772:

plc function ref - 34.22 MVM - MoVe

- Page 773 and 774:

plc function ref - 34.24 FAL - File

- Page 775 and 776:

plc function ref - 34.26 FSC - File

- Page 777 and 778:

plc function ref - 34.28 FFL, FFU,

- Page 779 and 780:

plc function ref - 34.30 SQO - SeQu

- Page 781 and 782:

plc function ref - 34.32 JSR/SBR/RE

- Page 783 and 784:

plc function ref - 34.34 34.1.11 Ad

- Page 785 and 786:

plc function ref - 34.36 PID - Prop

- Page 787 and 788:

plc function ref - 34.38 ACI, AIC -

- Page 789 and 790:

plc function ref - 34.40 ARD, ARL -

- Page 791 and 792:

plc function ref - 34.42 AWT, AWA -

- Page 793 and 794:

plc function ref - 34.44 Table 1: I

- Page 795 and 796:

plc function ref - 34.46 Table 1: I

- Page 797 and 798:

plc function ref - 34.48 Table 1: I

- Page 799 and 800:

plc glossary - 35.2 analysis - the

- Page 801 and 802:

plc glossary - 35.4 decimal(base 10

- Page 803 and 804:

plc glossary - 35.6 CAD (Computer A

- Page 805 and 806:

plc glossary - 35.8 intermittent no

- Page 807 and 808:

plc glossary - 35.10 geometric dime

- Page 809 and 810:

plc glossary - 35.12 EPROM (Erasabl

- Page 811 and 812:

plc glossary - 35.14 ground - a bur

- Page 813 and 814:

plc glossary - 35.16 IOR (Inclusive

- Page 815 and 816:

plc glossary - 35.18 pneumatic syst

- Page 817 and 818:

plc glossary - 35.20 nonpositive di

- Page 819 and 820:

plc glossary - 35.22 photon - a sin

- Page 821 and 822:

plc glossary - 35.24 after a US fed

- Page 823 and 824:

plc glossary - 35.26 manufacturabil

- Page 825 and 826:

plc glossary - 35.28 time-proportio

- Page 827 and 828:

plc glossary - 35.30 it assumes the

- Page 829 and 830:

plc references - 36.2 USA. Telemech

- Page 831 and 832:

plc references - 36.4 Second Editio

- Page 833 and 834:

gfdl - 37.1 37. GNU Free Documentat

- Page 835 and 836:

gfdl - 37.3 cially, provided that t

- Page 837 and 838:

gfdl - 37.5 Sections in the Modifie

- Page 839:

gfdl - 37.7 tion License from time