3 I 2012 - Grandhotel Pupp

3 I 2012 - Grandhotel Pupp

3 I 2012 - Grandhotel Pupp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

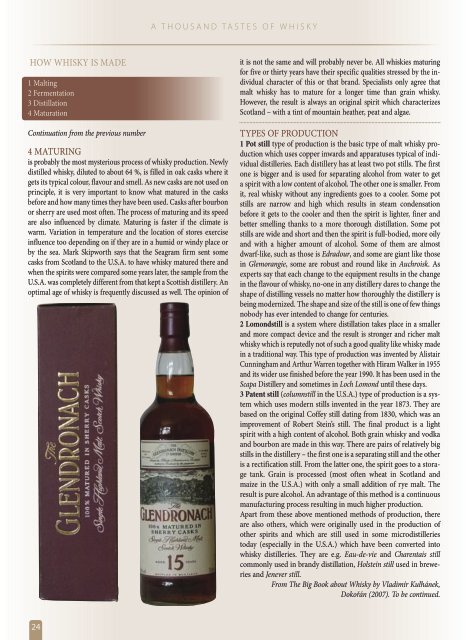

a thousand tastes of whisky<br />

How whisky is made<br />

1 Malting<br />

2 Fermentation<br />

3 Distillation<br />

4 Maturation<br />

Continuation from the previous number<br />

4 MATURING<br />

is probably the most mysterious process of whisky production. Newly<br />

distilled whisky, diluted to about 64 %, is filled in oak casks where it<br />

gets its typical colour, flavour and smell. As new casks are not used on<br />

principle, it is very important to know what matured in the casks<br />

before and how many times they have been used. Casks after bourbon<br />

or sherry are used most often. The process of maturing and its speed<br />

are also influenced by climate. Maturing is faster if the climate is<br />

warm. Variation in temperature and the location of stores exercise<br />

influence too depending on if they are in a humid or windy place or<br />

by the sea. Mark Skipworth says that the Seagram firm sent some<br />

casks from Scotland to the U.S.A. to have whisky matured there and<br />

when the spirits were compared some years later, the sample from the<br />

U.S.A. was completely different from that kept a Scottish distillery. An<br />

optimal age of whisky is frequently discussed as well. The opinion of<br />

it is not the same and will probably never be. All whiskies maturing<br />

for five or thirty years have their specific qualities stressed by the individual<br />

character of this or that brand. Specialists only agree that<br />

malt whisky has to mature for a longer time than grain whisky.<br />

However, the result is always an original spirit which characterizes<br />

Scotland – with a tint of mountain heather, peat and algae.<br />

TYPES OF PRODUCTION<br />

1 Pot still type of production is the basic type of malt whisky production<br />

which uses copper inwards and apparatuses typical of individual<br />

distilleries. Each distillery has at least two pot stills. The first<br />

one is bigger and is used for separating alcohol from water to get<br />

a spirit with a low content of alcohol. The other one is smaller. From<br />

it, real whisky without any ingredients goes to a cooler. Some pot<br />

stills are narrow and high which results in steam condensation<br />

before it gets to the cooler and then the spirit is lighter, finer and<br />

better smelling thanks to a more thorough distillation. Some pot<br />

stills are wide and short and then the spirit is full-bodied, more oily<br />

and with a higher amount of alcohol. Some of them are almost<br />

dwarf-like, such as those is Edradour, and some are giant like those<br />

in Glemorangie, some are robust and round like in Auchroisk. As<br />

experts say that each change to the equipment results in the change<br />

in the flavour of whisky, no-one in any distillery dares to change the<br />

shape of distilling vessels no matter how thoroughly the distillery is<br />

being modernized. The shape and size of the still is one of few things<br />

nobody has ever intended to change for centuries.<br />

2 Lomondstill is a system where distillation takes place in a smaller<br />

and more compact device and the result is stronger and richer malt<br />

whisky which is reputedly not of such a good quality like whisky made<br />

in a traditional way. This type of production was invented by Alistair<br />

Cunningham and Arthur Warren together with Hiram Walker in 1955<br />

and its wider use finished before the year 1990. It has been used in the<br />

Scapa Distillery and sometimes in Loch Lomond until these days.<br />

3 Patent still (columnstill in the U.S.A.) type of production is a system<br />

which uses modern stills invented in the year 1873. They are<br />

based on the original Coffey still dating from 1830, which was an<br />

improvement of Robert Stein’s still. The final product is a light<br />

spirit with a high content of alcohol. Both grain whisky and vodka<br />

and bourbon are made in this way. There are pairs of relatively big<br />

stills in the distillery – the first one is a separating still and the other<br />

is a rectification still. From the latter one, the spirit goes to a storage<br />

tank. Grain is processed (most often wheat in Scotland and<br />

maize in the U.S.A.) with only a small addition of rye malt. The<br />

result is pure alcohol. An advantage of this method is a continuous<br />

manufacturing process resulting in much higher production.<br />

Apart from these above mentioned methods of production, there<br />

are also others, which were originally used in the production of<br />

other spirits and which are still used in some microdistilleries<br />

today (especially in the U.S.A.) which have been converted into<br />

whisky distilleries. They are e.g. Eau-de-vie and Charentais still<br />

commonly used in brandy distillation, Holstein still used in breweries<br />

and Jenever still.<br />

From The Big Book about Whisky by Vladimír Kulhánek,<br />

Dokořán (2007). To be continued.<br />

24