Scania annual report 2002

Scania annual report 2002

Scania annual report 2002

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The <strong>Scania</strong> Production System is based on<br />

four main principles.<br />

Standardised working method<br />

– the normal situation<br />

To ensure that <strong>Scania</strong>’s products maintain high, uniform<br />

quality, work processes have been standardised and<br />

documented. Tasks are performed in a specific way, at a<br />

specific pace and with an even, balanced flow throughout<br />

the production chain. In the <strong>Scania</strong> Production System<br />

(SPS), this is called the “normal situation”.<br />

Doing it right the first time<br />

Since work processes are controlled visually, with visible<br />

buffers and follow-up on bulletin boards, what is normal<br />

or abnormal becomes very clear. Direct feedback to the<br />

person who caused a deviation allows it to be acted upon<br />

quickly, helping to create a quality-assured work process.<br />

Consumption-controlled production<br />

Customer demand determines how many trucks, buses<br />

or engines will be manufactured. It is also the customer<br />

who determines when production will begin. This principle<br />

permeates the entire <strong>Scania</strong> production chain, from the<br />

customer’s order to the local sales company through production<br />

and assembly to the final product that is ready<br />

for delivery.<br />

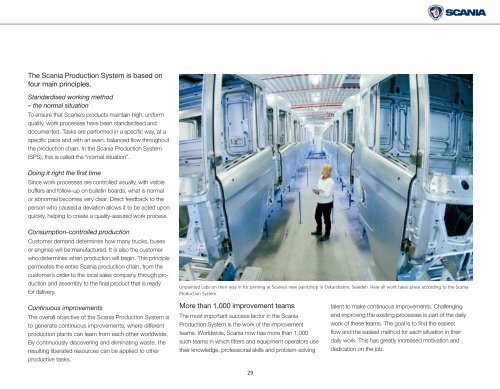

Unpainted cabs on their way in for priming at <strong>Scania</strong>’s new paintshop in Oskarshamn, Sweden. Here all work takes place according to the <strong>Scania</strong><br />

Production System.<br />

Continuous improvements<br />

The overall objective of the <strong>Scania</strong> Production System is<br />

to generate continuous improvements, where different<br />

production plants can learn from each other worldwide.<br />

By continuously discovering and eliminating waste, the<br />

resulting liberated resources can be applied to other<br />

productive tasks.<br />

More than 1,000 improvement teams<br />

The most important success factor in the <strong>Scania</strong><br />

Production System is the work of the improvement<br />

teams. Worldwide, <strong>Scania</strong> now has more than 1,000<br />

such teams in which fitters and equipment operators use<br />

their knowledge, professional skills and problem-solving<br />

29<br />

talent to make continuous improvements. Challenging<br />

and improving the existing processes is part of the daily<br />

work of these teams. The goal is to find the easiest<br />

flow and the easiest method for each situation in their<br />

daily work. This has greatly increased motivation and<br />

dedication on the job.