- Page 1 and 2:

FINAL REPORT Scientific Understandi

- Page 3 and 4:

This report was prepared under cont

- Page 5 and 6:

List of Acronyms AES Atomic Emissio

- Page 7 and 8:

List of Figures Figure 1.1. Figure

- Page 9 and 10:

Figure 1.21. Figure 1.22. Figure 1.

- Page 11 and 12:

Figure 1.38. Figure 1.39. Figure 1.

- Page 13 and 14:

Figure 2.26. Figure 2.27. Figure 2.

- Page 15 and 16:

Figure 3.11. Cathodic polarization

- Page 17 and 18:

Figure 3.31. Figure 3.32. Figure 3.

- Page 19 and 20:

Figure 4.12. Average Roughness of R

- Page 21 and 22:

Figure 5.4. Figures 5.5. Apparatus

- Page 23 and 24:

Figure 5.36. Figure 5.37. R paramet

- Page 25 and 26:

Figure 6.23. Two commercial samples

- Page 27 and 28:

Figure 7.1. a) instrumental configu

- Page 29 and 30:

List of Tables Table 1.1. Table 1.2

- Page 31 and 32:

Table 6.4. Processing parameters fo

- Page 33 and 34:

Keywords 1. Al alloys 2. Non-chroma

- Page 35 and 36:

1. Executive Summary This report su

- Page 37 and 38:

the role of electrophoresis in inhi

- Page 39 and 40:

occurring at low pHs and release at

- Page 41 and 42:

were obtained by a post treatment w

- Page 43 and 44:

4. G.O. Ilevbare, J.R. Scully, J. Y

- Page 45 and 46:

3. Objective The primary objective

- Page 47 and 48:

5. Results and Accomplishments In t

- Page 49 and 50:

powder, slurried with ultrapure wat

- Page 51 and 52:

TCP-coated AA2024-T3. A Kratos AXIS

- Page 53 and 54:

X-ray Photoelectron Spectroscopy (X

- Page 55 and 56:

Potential (V vs. Ag/AgCl) -0.2 -0.3

- Page 57 and 58:

Signal Intensity (counts/s) assessi

- Page 59 and 60:

Al (including both Al 0 and Al 3+ c

- Page 61 and 62:

TEM or during sample preparation, s

- Page 63 and 64:

Potential (V vs. Ag/AgCl) and uncoa

- Page 65 and 66:

5.1.4.8 Effects of Aging on the Fil

- Page 67 and 68:

Intensity (counts/s) Concentration

- Page 69 and 70:

|Z| 0.01Hz (ohm cm 2 ) |Z| 0.01Hz (

- Page 71 and 72:

The artificial scratch cell was als

- Page 73 and 74:

Raman intensity, a.u. 4000 880 3500

- Page 75 and 76:

Figure 1.24. Raman spectra for the

- Page 77 and 78:

peak at 520 cm -1 and an intense Cr

- Page 79 and 80:

Figure 1.28. Plots of the intensity

- Page 81 and 82:

Figure 1.30. (A) Video micrograph o

- Page 83 and 84:

The Zr and O signals arise from the

- Page 85 and 86:

Figure 1.35. (A) Corrosion potentia

- Page 87 and 88:

Table 1.1. Corrosion current (i cor

- Page 89 and 90:

additional pitting. The TCP coating

- Page 91 and 92:

Figure 1.41. Cr(VI) peak intensity

- Page 93 and 94:

Work is ongoing to understand how t

- Page 95 and 96:

9. L. Li, D-Y. Kim and G. M. Swain,

- Page 97 and 98:

carefully rinsed with DI water, air

- Page 99 and 100:

decrease to a net anodic current in

- Page 101 and 102:

Potential (mV vs. SCE) Potential (m

- Page 103 and 104:

i (A/cm 2 ) Immediately after silic

- Page 105 and 106:

Potential (mV vs. SCE) Potential (m

- Page 107 and 108:

Potential (mV vs. SCE) Rp (ohm.cm 2

- Page 109 and 110:

Potential (mV vs. SCE) Potential (m

- Page 111 and 112:

2.4.4 In situ AFM Scratching Result

- Page 113 and 114:

Figure 2.31. In situ AFM scratching

- Page 115 and 116:

(2.3) Figure 2.35. Specie diagram f

- Page 117 and 118:

concentration and the silicon to ca

- Page 119 and 120:

analysis coupled with XPS revealed

- Page 121 and 122:

5.2.4.4 In Situ AFM Scratching Befo

- Page 123 and 124:

esults in the formation of silicate

- Page 125 and 126:

26. P. Schmutz and G.S. Frankel, J.

- Page 127 and 128:

Pr 3+ , Y 3+ showed [12] an order o

- Page 129 and 130:

0.1M NaCl solution with varying con

- Page 131 and 132:

8.7 through pH 12.6 due to the lowe

- Page 133 and 134:

(b) (c) 99

- Page 135 and 136:

immersed in Ce 3+ remained bright w

- Page 137 and 138:

S phase and dissolution of Al matri

- Page 139 and 140:

Corrosion rate, i corr (A/cm 2 ) 6x

- Page 141 and 142:

I L (microA) 600 500 400 300 NC (-8

- Page 143 and 144:

than that of chromate[35]. Historic

- Page 145 and 146:

coupon was immersed with the polish

- Page 147 and 148:

5.3.2.4 Results 5.3.2.4.1 Speciatio

- Page 149 and 150:

(c) Figure 3.8. Speciation diagram

- Page 151 and 152:

E vs. SCE (V) -0.70 -0.75 -0.80 -0.

- Page 153 and 154:

E vs. SCE (V) 1000 rpm E vs. SCE (V

- Page 155 and 156:

Chemical quantification showed a me

- Page 157 and 158:

(a) (b) Figure 3.15. (a) (top) SEM

- Page 159 and 160:

E vs. SCE (V) E vs. SCE (V) E vs. S

- Page 161 and 162:

-Z" (ohm) -Z" (ohm) -Z" (ohm) -Z" (

- Page 163 and 164:

(Figure 3.8b). However, no effect o

- Page 165 and 166:

CPS CPS CPS x 2 14 10 12 10 8 6 4 2

- Page 167 and 168:

CPS CPS 100 95 90 85 80 75 70 x 10

- Page 169 and 170:

I k L 0. 2 1 2 AnFC B D 2 3 O 1

- Page 171 and 172:

i -800 (A/cm 2 ) 10 -4 NaCl NaCl+5

- Page 173 and 174:

Corrosion rate ( 1/R p ) ohm -1 cm

- Page 175 and 176:

particles compared to zinc-free sol

- Page 177 and 178:

and Zn bentonite compounds have red

- Page 179 and 180:

2) Deoxidizing for 3 minutes in an

- Page 181 and 182:

Scintag (now ThermoARL) Pad-V TM an

- Page 183 and 184:

Table 3.5. Characterization of bent

- Page 185 and 186:

Zn 2+ cation release (meq/100g) Pr

- Page 187 and 188:

(a) (b) (c) Figure 3.33. (a) An exp

- Page 189 and 190:

|Z| (ohm) Phase angle (degrees) 5.3

- Page 191 and 192:

|Z| at 0.01 Hz (ohm.cm 2 ) Pore Res

- Page 193 and 194:

|Z| at 0.01 Hz (ohm.cm 2 ) |Z| at 0

- Page 195 and 196:

pigmented coatings exhibited partia

- Page 197 and 198:

5.3.3.6 Conclusions 1. Exchange ben

- Page 199 and 200:

39. M. Mahdavian and M. M. Attar, P

- Page 201 and 202:

100. F.Liebau, Structural Chemistry

- Page 203 and 204:

of the coated sample, which is tigh

- Page 205 and 206:

Lubricant Blue (Struers) was used f

- Page 207 and 208:

good grip on the dolly, the equipme

- Page 209 and 210:

Pressure (kPa) r (mm) Pressure x Ra

- Page 211 and 212:

Pressure x Radius (kN/m) plateau bu

- Page 213 and 214:

Pressure x Radius (kN/m) Pxr (KN/m)

- Page 215 and 216:

Average Roughness (m) In contrast,

- Page 217 and 218:

Adhesion Strength (J/m 2 ) PVB PVB

- Page 219 and 220:

Pressure (kPa) Constant Infusion up

- Page 221 and 222:

(a) (b) (c) (d) Figure 4.19. Coatin

- Page 223 and 224:

Min. Potential (V vs SHE) Min. Pote

- Page 225 and 226:

Pressure (kPa) exposure in hot wate

- Page 227 and 228:

Engineering Stress (MPa) slope of t

- Page 229 and 230:

Adhesion Strength (J/m 2 ) ASTM D33

- Page 231 and 232:

Pressure (kPa) Pressure (kPa) Radiu

- Page 233 and 234:

Adhesion Strength (J/m 2 ) Pressure

- Page 235 and 236:

Table 4.7. Adhesion Strength values

- Page 237 and 238:

Non-Cl./Deox. No CC Cleaned/Deox. N

- Page 239 and 240:

5.4.5 Conclusions and Implications

- Page 241 and 242:

5.5 Task 5: Inhibitor Activation an

- Page 243 and 244:

solution for equilibration at contr

- Page 245 and 246:

Table 5.2. Techniques applied to sp

- Page 247 and 248:

The capacitance was determined by E

- Page 249 and 250:

combination with zinc molybdate, a

- Page 251 and 252:

Concentration, mmol / L Final pH te

- Page 253 and 254:

Alkaline affects praseodymium solub

- Page 255 and 256:

MoO 4 2- ) inhibition to the system

- Page 257 and 258:

Zinc molybdate is reported to be si

- Page 259 and 260:

The presence of a salt that has no

- Page 261 and 262: This approach yields two figures of

- Page 263 and 264: Inhibitor mapping of the Hentzen 16

- Page 265 and 266: The molybdate loss in the strontium

- Page 267 and 268: The capacitance dC is given by 0 (

- Page 269 and 270: 2 C( r, t) C( r )[1 r 2 exp( D nt

- Page 271 and 272: -thea (degree) logIZI (Ohm-Cm 2 ) P

- Page 273 and 274: Capacitance (F) respectively. The c

- Page 275 and 276: Capacitance (F) Weight gain (g) For

- Page 277 and 278: Normalized Capacitance Change Norma

- Page 279 and 280: Potential V (Ag/AgCl) Corrosion rat

- Page 281 and 282: 5.5.4.7 Nanopore structure characte

- Page 283 and 284: Normaalized Transport Rate (g/m^2_d

- Page 285 and 286: S-Parameter S-Parameter Penetration

- Page 287 and 288: S-Parameter S-Parameter Penetration

- Page 289 and 290: R-parameter R-parameter Penetration

- Page 291 and 292: 5. T. M. Letcher, “Thermodynamics

- Page 293 and 294: pigment of CaSiO 3 with initial pH

- Page 295 and 296: allowed a comparison of the differe

- Page 297 and 298: The solution resistance (R sol ) va

- Page 299 and 300: Theta [degrees] theta |Z| [ohm] 10

- Page 301 and 302: C [F/cm2] Rcorr [ohm*cm2] 7075-AHN

- Page 303 and 304: C [F/cm 2 ] Rcorr [ohm*cm 2 ] Rcorr

- Page 305 and 306: Visual TTF [hours] Table 6.2. Param

- Page 307 and 308: of Metallast pre-treatment, which h

- Page 309 and 310: Prediction of the TTF obtained by A

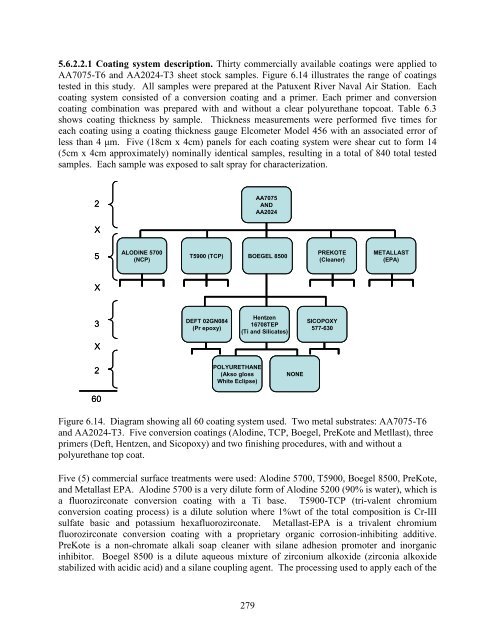

- Page 311: 5.6.2 Electrochemical Impedance Spe

- Page 315 and 316: Table 6.4. Processing parameters fo

- Page 317 and 318: population of total TTF vectors th

- Page 319 and 320: components of the impedance and the

- Page 321 and 322: Figure 6.17. EIS spectra for sample

- Page 323 and 324: Figure 6.18. Kaplan-Meier survival

- Page 325 and 326: Maximum c i range Maximum ci range

- Page 327 and 328: The type and number of input neuron

- Page 329 and 330: Predicted TTF The BFM method, intro

- Page 331 and 332: The most significant variables to i

- Page 333 and 334: 5.6.3 Characterization of Pigment D

- Page 335 and 336: of sputtering gold and carbon paint

- Page 337 and 338: Figure 6.26. Cross-sectional view o

- Page 339 and 340: Figure 6.28. EDX maps of primer cro

- Page 341 and 342: Figure 6.31. EDX maps of primer cro

- Page 343 and 344: In Figure 6.34, Ca and Si existed a

- Page 345 and 346: Table 6.8. Average percentage resid

- Page 347 and 348: strictly limited due to the barrier

- Page 349 and 350: Figure 6.37. Coating systems in det

- Page 351 and 352: Each corrosion volume of scribed ar

- Page 353 and 354: Corrosion Area (mm 2 ) 1200 1000 80

- Page 355 and 356: Corrosion Area (mm 2 ) Corrosion Ra

- Page 357 and 358: Corrosion Rate (mm/yr) Corrosion Vo

- Page 359 and 360: Corrosion Area (mm 2 ) corrosion ra

- Page 361 and 362: corrosion rate (mm/yr) Corrosion Vo

- Page 363 and 364:

Corrosion Volume (mm/yr) Corrosion

- Page 365 and 366:

ate, PPG CA7233 coated samples had

- Page 367 and 368:

Appendix 6B Table 6B.1. Corrosion v

- Page 369 and 370:

Table 6B.3. Corrosion rate of sampl

- Page 371 and 372:

Table 6B.5. Corrosion area of sampl

- Page 373 and 374:

5.7. Task 7: Characterization of Lo

- Page 375 and 376:

at 65C. After using DI water to rin

- Page 377 and 378:

Transmission Mode Conduct EIS measu

- Page 379 and 380:

Cdl(F/cm 2 ) Rp(.cm 2 ) relatively

- Page 381 and 382:

pit bottom area (cm 2 ) pit bottom

- Page 383 and 384:

2days 2days 1mm 1mm 7days 7days Pit

- Page 385 and 386:

(a) (b) Si Si O Al Na Ca K Si Al-Cu

- Page 387 and 388:

Pit 1 and pit 2 as shown in Figure

- Page 389 and 390:

In these experiments, Deft primers

- Page 391 and 392:

For the case of as-deposited thin f

- Page 393 and 394:

3. L. Balazs, Physica E, 54, 1183-1

- Page 395 and 396:

and subsequently re-oxidized in two

- Page 397 and 398:

not represent true adhesion strengt

- Page 399 and 400:

• The pit morphology in 0.5 M NaC

- Page 401 and 402:

Appendix 2. List of Scientific/Tech

- Page 403 and 404:

“The Secret Life of Chromate Free