July 25, 2012 - Toho Water Authority

July 25, 2012 - Toho Water Authority

July 25, 2012 - Toho Water Authority

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

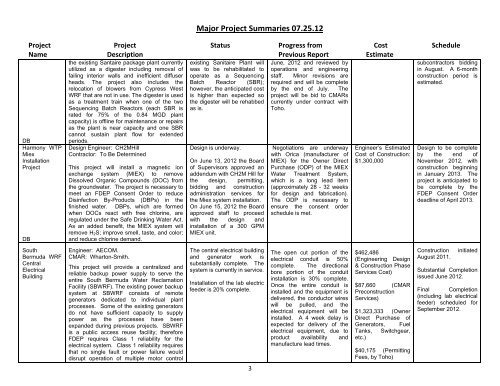

Major Project Summaries 07.<strong>25</strong>.12<br />

Project Project Status Progress from Cost Schedule<br />

Name Description Previous Report Estimate<br />

DB<br />

Harmony WTP<br />

Miex<br />

Installation<br />

Project<br />

DB<br />

the existing Santaire package plant currently<br />

utilized as a digester including removal of<br />

failing interior walls and inefficient diffuser<br />

heads. The project also includes the<br />

relocation of blowers from Cypress West<br />

WRF that are not in use. The digester is used<br />

as a treatment train when one of the two<br />

Sequencing Batch Reactors (each SBR is<br />

rated for 75% of the 0.84 MGD plant<br />

capacity) is offline for maintenance or repairs<br />

as the plant is near capacity and one SBR<br />

cannot sustain plant flow for extended<br />

periods.<br />

Design Engineer: CH2MHill<br />

Contractor: To Be Determined<br />

This project will install a magnetic ion<br />

exchange system (MIEX) to remove<br />

Dissolved Organic Compounds (DOC) from<br />

the groundwater. The project is necessary to<br />

meet an FDEP Consent Order to reduce<br />

Disinfection By-Products (DBPs) in the<br />

finished water. DBPs, which are formed<br />

when DOCs react with free chlorine, are<br />

regulated under the Safe Drinking <strong>Water</strong> Act.<br />

As an added benefit, the MIEX system will<br />

remove H 2 S; improve smell, taste, and color;<br />

and reduce chlorine demand.<br />

existing Sanitaire Plant will<br />

was to be rehabilitated to<br />

operate as a Sequencing<br />

Batch Reactor (SBR);<br />

however, the anticipated cost<br />

is higher than expected so<br />

the digester will be rehabbed<br />

as is.<br />

Design is underway.<br />

On June 13, <strong>2012</strong> the Board<br />

of Supervisors approved an<br />

addendum with CH2M Hill for<br />

the design, permitting,<br />

bidding and construction<br />

administration services for<br />

the Miex system installation.<br />

On June 15, <strong>2012</strong> the Board<br />

approved staff to proceed<br />

with the design and<br />

installation of a 300 GPM<br />

MIEX unit.<br />

June, <strong>2012</strong> and reviewed by<br />

operations and engineering<br />

staff. Minor revisions are<br />

required and will be complete<br />

by the end of <strong>July</strong>. The<br />

project will be bid to CMARs<br />

currently under contract with<br />

<strong>Toho</strong>.<br />

Negotiations are underway<br />

with Orica (manufacturer of<br />

MIEX) for the Owner Direct<br />

Purchase (ODP) of the MIEX<br />

<strong>Water</strong> Treatment System,<br />

which is a long lead item<br />

(approximately 28 - 32 weeks<br />

for design and fabrication).<br />

The ODP is necessary to<br />

ensure the consent order<br />

schedule is met.<br />

Engineer’s Estimated<br />

Cost of Construction:<br />

$1,300,000<br />

subcontractors bidding<br />

in August. A 6-month<br />

construction period is<br />

estimated.<br />

Design to be complete<br />

by the end of<br />

November <strong>2012</strong>, with<br />

construction beginning<br />

in January 2013. The<br />

project is anticipated to<br />

be complete by the<br />

FDEP Consent Order<br />

deadline of April 2013.<br />

South<br />

Bermuda WRF<br />

Central<br />

Electrical<br />

Building<br />

Engineer: AECOM.<br />

CMAR: Wharton-Smith.<br />

This project will provide a centralized and<br />

reliable backup power supply to serve the<br />

entire South Bermuda <strong>Water</strong> Reclamation<br />

Facility (SBWRF). The existing power backup<br />

system at SBWRF consists of remote<br />

generators dedicated to individual plant<br />

processes. Some of the existing generators<br />

do not have sufficient capacity to supply<br />

power as the processes have been<br />

expanded during previous projects. SBWRF<br />

is a public access reuse facility; therefore<br />

FDEP requires Class 1 reliability for the<br />

electrical system. Class 1 reliability requires<br />

that no single fault or power failure would<br />

disrupt operation of multiple motor control<br />

The central electrical building<br />

and generator work is<br />

substantially complete. The<br />

system is currently in service.<br />

Installation of the lab electric<br />

feeder is 20% complete.<br />

3<br />

The open cut portion of the<br />

electrical conduit is 50%<br />

complete. The directional<br />

bore portion of the conduit<br />

installation is 30% complete.<br />

Once the entire conduit is<br />

installed and the equipment is<br />

delivered, the conductor wires<br />

will be pulled, and the<br />

electrical equipment will be<br />

installed. A 4 week delay is<br />

expected for delivery of the<br />

electrical equipment, due to<br />

product availability and<br />

manufacture lead times.<br />

$462,486<br />

(Engineering Design<br />

& Construction Phase<br />

Services Cost)<br />

$87,660 (CMAR<br />

Preconstruction<br />

Services)<br />

$1,323,333 (Owner<br />

Direct Purchase of<br />

Generators, Fuel<br />

Tanks, Switchgear,<br />

etc.)<br />

$40,175 (Permitting<br />

Fees, by <strong>Toho</strong>)<br />

Construction<br />

August 2011.<br />

initiated<br />

Substantial Completion<br />

issued June <strong>2012</strong>.<br />

Final Completion<br />

(including lab electrical<br />

feeder) scheduled for<br />

September <strong>2012</strong>.