ecoTEC pro - Vaillant

ecoTEC pro - Vaillant

ecoTEC pro - Vaillant

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10 Commissioning<br />

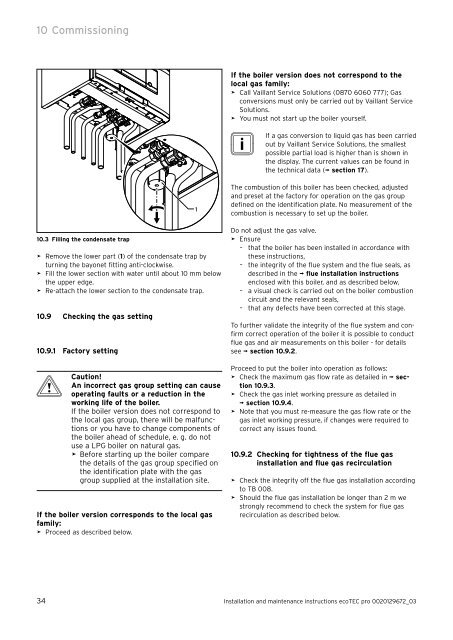

10.3 Filling the condensate trap<br />

> Remove the lower part (1) of the condensate trap by<br />

turning the bayonet fitting anti-clockwise.<br />

> Fill the lower section with water until about 10 mm below<br />

the upper edge.<br />

> Re-attach the lower section to the condensate trap.<br />

10.9 Checking the gas setting<br />

10.9.1 Factory setting<br />

b<br />

Caution!<br />

An incorrect gas group setting can cause<br />

operating faults or a reduction in the<br />

working life of the boiler.<br />

If the boiler version does not correspond to<br />

the local gas group, there will be malfunctions<br />

or you have to change components of<br />

the boiler ahead of schedule, e. g. do not<br />

use a LPG boiler on natural gas.<br />

> Before starting up the boiler compare<br />

the details of the gas group specified on<br />

the identification plate with the gas<br />

group supplied at the installation site.<br />

If the boiler version corresponds to the local gas<br />

family:<br />

> Proceed as described below.<br />

1<br />

If the boiler version does not correspond to the<br />

local gas family:<br />

> Call <strong>Vaillant</strong> Service Solutions (0870 6060 777); Gas<br />

conversions must only be carried out by <strong>Vaillant</strong> Service<br />

Solutions.<br />

> You must not start up the boiler yourself.<br />

i If<br />

a gas conversion to liquid gas has been carried<br />

out by <strong>Vaillant</strong> Service Solutions, the smallest<br />

possible partial load is higher than is shown in<br />

the display. The current values can be found in<br />

the technical data (¬ section 17).<br />

The combustion of this boiler has been checked, adjusted<br />

and preset at the factory for operation on the gas group<br />

defined on the identification plate. No measurement of the<br />

combustion is necessary to set up the boiler.<br />

Do not adjust the gas valve.<br />

> Ensure<br />

– that the boiler has been installed in accordance with<br />

these instructions,<br />

– the integrity of the flue system and the flue seals, as<br />

described in the ¬ flue installation instructions<br />

enclosed with this boiler, and as described below,<br />

– a visual check is carried out on the boiler combustion<br />

circuit and the relevant seals,<br />

– that any defects have been corrected at this stage.<br />

To further validate the integrity of the flue system and confirm<br />

correct operation of the boiler it is possible to conduct<br />

flue gas and air measurements on this boiler - for details<br />

see ¬ section 10.9.2.<br />

Proceed to put the boiler into operation as follows:<br />

> Check the maximum gas flow rate as detailed in ¬ section<br />

10.9.3.<br />

> Check the gas inlet working pressure as detailed in<br />

¬ section 10.9.4.<br />

> Note that you must re-measure the gas flow rate or the<br />

gas inlet working pressure, if changes were required to<br />

correct any issues found.<br />

10.9.2 Checking for tightness of the flue gas<br />

installation and flue gas recirculation<br />

> Check the integrity off the flue gas installation according<br />

to TB 008.<br />

> Should the flue gas installation be longer than 2 m we<br />

strongly recommend to check the system for flue gas<br />

recirculation as described below.<br />

34 Installation and maintenance instructions <strong>ecoTEC</strong> <strong>pro</strong> 0020129672_03