ecoTEC pro - Vaillant

ecoTEC pro - Vaillant

ecoTEC pro - Vaillant

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

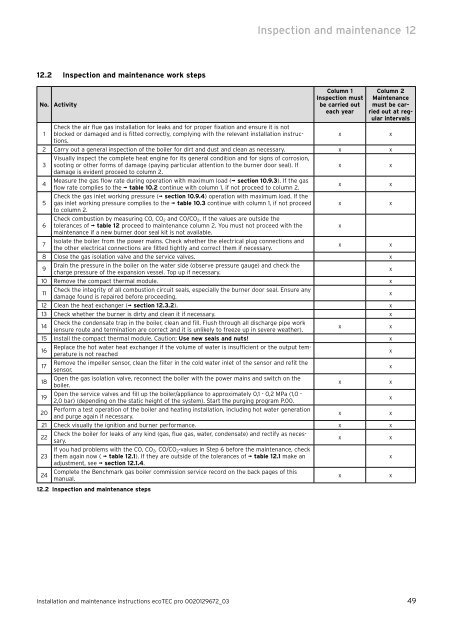

12.2 Inspection and maintenance work steps<br />

No. Activity<br />

Inspection and maintenance 12<br />

Column 1<br />

Inspection must<br />

be carried out<br />

each year<br />

Column 2<br />

Maintenance<br />

must be carried<br />

out at regular<br />

intervals<br />

1<br />

Check the air flue gas installation for leaks and for <strong>pro</strong>per fixation and ensure it is not<br />

blocked or damaged and is fitted correctly, complying with the relevant installation instructions.<br />

x x<br />

2 Carry out a general inspection of the boiler for dirt and dust and clean as necessary.<br />

Visually inspect the complete heat engine for its general condition and for signs of corrosion,<br />

x x<br />

3 sooting or other forms of damage (paying particular attention to the burner door seal). If<br />

damage is evident <strong>pro</strong>ceed to column 2.<br />

x x<br />

4<br />

Measure the gas flow rate during operation with maximum load (¬ section 10.9.3). If the gas<br />

flow rate complies to the ¬ table 10.2 continue with column 1, if not <strong>pro</strong>ceed to column 2.<br />

Check the gas inlet working pressure (¬ section 10.9.4) operation with maximum load. If the<br />

x x<br />

5 gas inlet working pressure complies to the ¬ table 10.3 continue with column 1, if not <strong>pro</strong>ceed<br />

to column 2.<br />

x x<br />

Check combustion by measuring CO, CO2 and CO/CO2. If the values are outside the<br />

6 tolerances of ¬ table 12 <strong>pro</strong>ceed to maintenance column 2. You must not <strong>pro</strong>ceed with the<br />

maintenance if a new burner door seal kit is not available.<br />

x<br />

7<br />

Isolate the boiler from the power mains. Check whether the electrical plug connections and<br />

the other electrical connections are fitted tightly and correct them if necessary.<br />

x x<br />

8 Close the gas isolation valve and the service valves. x<br />

9<br />

Drain the pressure in the boiler on the water side (observe pressure gauge) and check the<br />

charge pressure of the expansion vessel. Top up if necessary.<br />

x<br />

10 Remove the compact thermal module. x<br />

11<br />

Check the integrity of all combustion circuit seals, especially the burner door seal. Ensure any<br />

damage found is repaired before <strong>pro</strong>ceeding.<br />

x<br />

12 Clean the heat exchanger (¬ section 12.3.2). x<br />

13 Check whether the burner is dirty and clean it if necessary. x<br />

14<br />

Check the condensate trap in the boiler, clean and fill. Flush through all discharge pipe work<br />

(ensure route and termination are correct and it is unlikely to freeze up in severe weather).<br />

x x<br />

15 Install the compact thermal module. Caution: Use new seals and nuts! x<br />

16<br />

Replace the hot water heat exchanger if the volume of water is insufficient or the output temperature<br />

is not reached<br />

x<br />

17<br />

Remove the impeller sensor, clean the filter in the cold water inlet of the sensor and refit the<br />

sensor.<br />

x<br />

18<br />

Open the gas isolation valve, reconnect the boiler with the power mains and switch on the<br />

boiler.<br />

x x<br />

19<br />

Open the service valves and fill up the boiler/appliance to ap<strong>pro</strong>ximately 0,1 - 0,2 MPa (1,0 -<br />

2,0 bar) (depending on the static height of the system). Start the purging <strong>pro</strong>gram P.00.<br />

x<br />

20<br />

Perform a test operation of the boiler and heating installation, including hot water generation<br />

and purge again if necessary.<br />

x x<br />

21 Check visually the ignition and burner performance. x x<br />

22<br />

Check the boiler for leaks of any kind (gas, flue gas, water, condensate) and rectify as necessary.<br />

x x<br />

If you had <strong>pro</strong>blems with the CO, CO2, CO/CO2-values in Step 6 before the maintenance, check<br />

23 them again now ( ¬ table 12.1). If they are outside of the tolerances of ¬ table 12.1 make an<br />

adjustment, see ¬ section 12.1.4.<br />

x<br />

24<br />

Complete the Benchmark gas boiler commission service record on the back pages of this<br />

manual.<br />

x x<br />

12.2 Inspection and maintenance steps<br />

Installation and maintenance instructions <strong>ecoTEC</strong> <strong>pro</strong> 0020129672_03 49