V. Focused Fundamental Research - EERE - U.S. Department of ...

V. Focused Fundamental Research - EERE - U.S. Department of ...

V. Focused Fundamental Research - EERE - U.S. Department of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

V.B.7 Role <strong>of</strong> Surface Chemistry on the Cycling and Rate Capability <strong>of</strong> Li Positive Electrode Materials (MIT)<br />

Shao-Horn – MIT<br />

Considering XPS analysis <strong>of</strong> powder LiOH (not shown)<br />

indicated that the surface region <strong>of</strong> LiOH consisted mostly<br />

<strong>of</strong> lithium carbonate, the surface region <strong>of</strong> reference Li 2 O 2<br />

powder observed here more likely consists <strong>of</strong> Li 2 O 2 . The O<br />

1s spectrum <strong>of</strong> Li 2 O reference powder (Figure V - 36, right<br />

panel) consists <strong>of</strong> two components: 1) a major component<br />

at 530.9 eV, which is close to those reported for LiOH; 2)<br />

a minor component (~2%) at 528.4 eV, which is attributed<br />

to O 2- ion in Li 2 O. Based on the major component at 530.9<br />

eV, it is postulated that the surface <strong>of</strong> reference Li 2 O is<br />

largely LiOH in nature as Li 2 O is known to be extremely<br />

moisture-sensitive.<br />

The O 1s regions for the pristine electrodes (Figure V -<br />

36, left panel) display a double peak structure that can be<br />

associated with oxygen bond to CF x groups (i.e., CF-O<br />

CF 2 ) at 535 eV and SO 3 groups at 532 eV in Nafion. After<br />

discharge (Figure V - 36, right panel), the CF-O-CF 2<br />

component at 535 eV from Nafion disappeared, which<br />

indicates the buildup <strong>of</strong> discharge products on the<br />

electrode surface. The majority <strong>of</strong> the oxygen signal for<br />

the discharged electrodes is attributed to the formation <strong>of</strong><br />

Li 2 O 2 at 531.0 eV for all discharge electrodes. However,<br />

the formation <strong>of</strong> LiOH cannot be ruled out. The formation<br />

<strong>of</strong> Li 2 O can be ruled out by the lack <strong>of</strong> an oxygen<br />

component with binding energy in the range <strong>of</strong> 528-529<br />

eV. In addition, a second component was identified at<br />

~533.0 eV for the discharged electrodes, which can be<br />

associated with Li 2 CO 3 and/or O-C=O (532.1 eV) and<br />

oxygen singly bonded with carbon atom in O-C=O (533.5<br />

eV). The formation <strong>of</strong> Li 2 O 2 (majority) and minority<br />

Li 2 CO 3 for all discharge electrodes is also supported by the<br />

Li 1s spectra <strong>of</strong> Figure V - 37.<br />

Electrochemical activity <strong>of</strong> high-energy Li-rich<br />

(Li 2 O) x (MO 2 )y systems. Positive electrodes <strong>of</strong> lithium<br />

peroxide and lithium oxide (Li 2 O x ) were shown to exhibit<br />

higher energy densities compared to LiCoO 2 cells (Bruce<br />

et al., JACS 2006). However, the overpotential required to<br />

charge the Li-Li 2 O x cells is ~1.5 V owing to the slow<br />

reaction rate associated with decomposing Li 2 O x . In order<br />

to efficiently operate the high energy Li-Li 2 O x cells, we<br />

have applied nanoparticles <strong>of</strong> platinum (Pt) and gold (Au)<br />

to facilitate the charging reaction rates where Pt was<br />

shown to have the highest charging activity among Pt, Au<br />

and carbon (Shao-Horn et al. ESSL, 2010). However, the<br />

utilization <strong>of</strong> precious Pt metal is not ideal. Therefore, it is<br />

crucial to identify highly active catalyst with abundant<br />

elements such as Mn, Fe. Co, and Ni for high energy Li<br />

Li 2 O 2 and Li-Li 2 O cells. Here we report the<br />

electrochemical activity for electro-oxidation <strong>of</strong> Li 2 O 2 on<br />

pure carbon, Pt/C, and 40 wt% Co 3 O 4 /C (Co 3 O 4 /C) by<br />

anodic polarization <strong>of</strong> Li 2 O 2 -filled positive electrodes in<br />

1 M LiTFSI DME at 5 mV/s. Co 3 O 4 nanoparticles (NPs)<br />

were synthesized as follows: A solution <strong>of</strong> 10 mL<br />

dichlorobenzene and 10 mL <strong>of</strong> oleylamine was prepared at<br />

room temperature (20°C) in a four-neck flask. The mixture<br />

was heated to 160°C under Ar atmosphere with continuous<br />

stirring. 400mg <strong>of</strong> Co 2 (CO) 8 in 4mL <strong>of</strong> dichlorobenzene<br />

was quickly injected into the above solution and left for 1<br />

hr. The solution was cooled down to room temperature,<br />

and CoO NPs were precipitated by ethanol addition and<br />

collected by centrifugation. The product was re-dispersed<br />

in hexane and separated by ethanol addition and<br />

centrifugation. This procedure was repeated 2 times. The<br />

as-synthesized CoO NPs were transferred to a porcelain<br />

boat and was annealed in a tube furnace at 500°C for 3 hrs<br />

under O 2 which lead to Co 3 O 4 NPs. The heat-treated Co 3 O 4<br />

NPs were loaded onto Vulcan Carbon (Co 3 O 4 : Carbon =<br />

2:3 w/w) yielding 40 wt% Co 3 O 4 /C. The particle<br />

dispersion <strong>of</strong> Co 3 O 4 NPs was uniform with average<br />

particle size 10 nm, as shown in Figure V - 38a.<br />

(a)<br />

(b)<br />

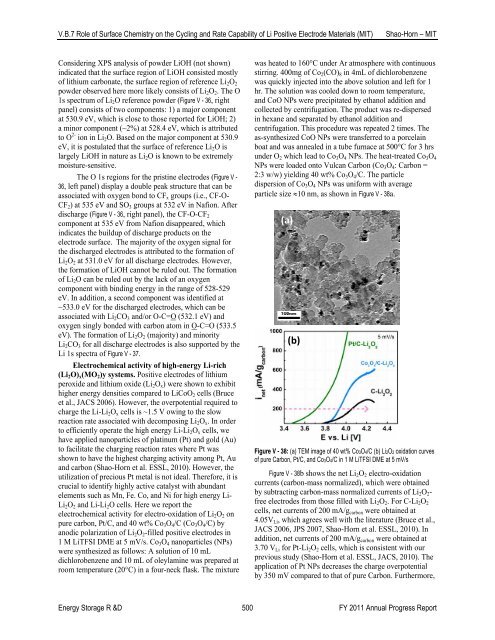

Figure V - 38: (a) TEM image <strong>of</strong> 40 wt% Co3O4/C (b) Li2O2 oxidation curves<br />

<strong>of</strong> pure Carbon, Pt/C, and Co3O4/C in 1 M LiTFSI DME at 5 mV/s<br />

Figure V - 38b shows the net Li 2 O 2 electro-oxidation<br />

currents (carbon-mass normalized), which were obtained<br />

by subtracting carbon-mass normalized currents <strong>of</strong> Li 2 O 2 <br />

free electrodes from those filled with Li 2 O 2 . For C-Li 2 O 2<br />

cells, net currents <strong>of</strong> 200 mA/g carbon were obtained at<br />

4.05V Li , which agrees well with the literature (Bruce et al.,<br />

JACS 2006, JPS 2007, Shao-Horn et al. ESSL, 2010). In<br />

addition, net currents <strong>of</strong> 200 mA/g carbon were obtained at<br />

3.70 V Li for Pt-Li 2 O 2 cells, which is consistent with our<br />

previous study (Shao-Horn et al. ESSL, JACS, 2010). The<br />

application <strong>of</strong> Pt NPs decreases the charge overpotential<br />

by 350 mV compared to that <strong>of</strong> pure Carbon. Furthermore,<br />

Energy Storage R &D 500 FY 2011 Annual Progress Report