V. Focused Fundamental Research - EERE - U.S. Department of ...

V. Focused Fundamental Research - EERE - U.S. Department of ...

V. Focused Fundamental Research - EERE - U.S. Department of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

V.B.8 Characterization <strong>of</strong> New Cathode Materials and Studies <strong>of</strong> Li-Air Batteries (BNL, U. Mass)<br />

Nam – U. Mass, Yang – BNL<br />

developing new diagnostic tools to investigate battery<br />

materials both in situ and ex situ, and then applies these to<br />

explain the relationships between structure and function<br />

for new materials.<br />

Connected with pump<br />

Approach<br />

1. In situ XAS and XRD studies <strong>of</strong> new electrode<br />

materials such as LiFe 1-y Mn y PO 4 and high capacity<br />

Li 1.2 Ni 0.2 Mn 0.6 O 2 during electrochemical cycling to<br />

carry out the diagnostic studies to improve the energy<br />

density and cycle life <strong>of</strong> Li-ion batteries.<br />

2. S<strong>of</strong>t XAS on the L-edges <strong>of</strong> Mn and Ni to distinguish<br />

the difference between the surface and the bulk<br />

structural changes caused by charge-discharge cycling<br />

for new cathode materials such as Li 1.2 Ni 0.2 Mn 0.6 O 2 .<br />

3. In situ and ex situ transmission electron microscopy<br />

(TEM) coupled with selected area electron diffraction<br />

(SAED) to study the structural changes <strong>of</strong> electrode<br />

materials with high location specification and spatial<br />

resolution.<br />

4. Electrochemical studies <strong>of</strong> GDE for Li-air batteries.<br />

5. Improve the performance <strong>of</strong> the GDE by surface<br />

modification.<br />

6. Design and synthesis <strong>of</strong> new electrolyte system with<br />

capability to dissolve Li 2 O and Li 2 O 2 , and/or high<br />

solubility <strong>of</strong> O 2 for Li-air batteries.<br />

Results<br />

Continued the in situ x-ray absorption and time<br />

resolved XRD studies <strong>of</strong> G2 and G3 cathode materials<br />

during heating<br />

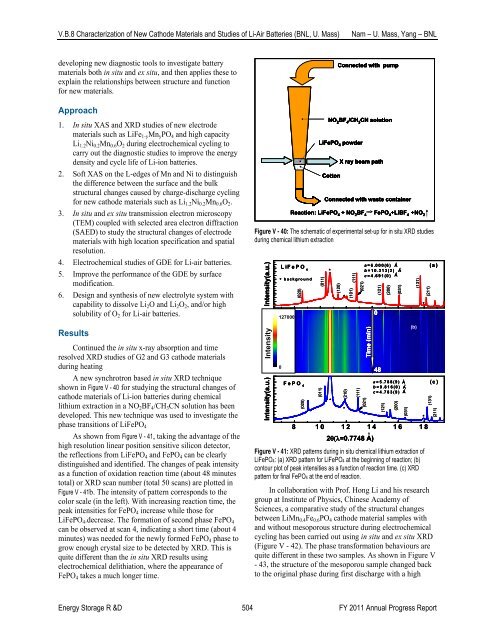

A new synchrotron based in situ XRD technique<br />

shown in Figure V - 40 for studying the structural changes <strong>of</strong><br />

cathode materials <strong>of</strong> Li-ion batteries during chemical<br />

lithium extraction in a NO 2 BF 4 /CH 3 CN solution has been<br />

developed. This new technique was used to investigate the<br />

phase transitions <strong>of</strong> LiFePO 4<br />

As shown from Figure V - 41, taking the advantage <strong>of</strong> the<br />

high resolution linear position sensitive silicon detector,<br />

the reflections from LiFePO 4 and FePO 4 can be clearly<br />

distinguished and identified. The changes <strong>of</strong> peak intensity<br />

as a function <strong>of</strong> oxidation reaction time (about 48 minutes<br />

total) or XRD scan number (total 50 scans) are plotted in<br />

Figure V - 41b. The intensity <strong>of</strong> pattern corresponds to the<br />

color scale (in the left). With increasing reaction time, the<br />

peak intensities for FePO 4 increase while those for<br />

LiFePO 4 .decrease. The formation <strong>of</strong> second phase FePO 4<br />

can be observed at scan 4, indicating a short time (about 4<br />

minutes) was needed for the newly formed FePO 4 phase to<br />

grow enough crystal size to be detected by XRD. This is<br />

quite different than the in situ XRD results using<br />

electrochemical delithiation, where the appearance <strong>of</strong><br />

FePO 4 takes a much longer time.<br />

Figure V - 40: The schematic <strong>of</strong> experimental set-up for in situ XRD studies<br />

during chemical lithium extraction<br />

Intensity(a.u.)<br />

Intensity<br />

Intensity(a.u.)<br />

127000<br />

0<br />

NO 2 BF 4 /CH 3 CN solution<br />

LiFePO 4 powder<br />

Cotton<br />

X ray beam path<br />

Connected with waste container<br />

Reaction: LiFePO 4<br />

+ NO 2<br />

BF<br />

---> 4 FePO 4 +LiBF 4 +NO 2<br />

LiFePO 4<br />

*<br />

background<br />

(020)<br />

FePO 4<br />

(020)<br />

(011)<br />

(011)<br />

*<br />

*<br />

(120)<br />

*<br />

(210)<br />

*<br />

(111)<br />

(101)<br />

(111)<br />

(021)<br />

a =6.000(6)<br />

A<br />

b =10.313(2)<br />

c =4.691(0)<br />

Time (min)<br />

(021)<br />

(121)<br />

0<br />

48<br />

(200)<br />

o<br />

A o Ao<br />

(031)<br />

a =5.788(9)<br />

A o b =9.816(0)<br />

A o<br />

c =4.783(9)<br />

A o<br />

(121)<br />

(200)<br />

(031)<br />

(131)<br />

(b)<br />

8 1 0 1 2 1 4 1 6 1 8<br />

2<br />

=0.774<br />

.7748 A)<br />

Figure V - 41: XRD patterns during in situ chemical lithium extraction <strong>of</strong><br />

LiFePO4: (a) XRD pattern for LiFePO4 at the beginning <strong>of</strong> reaction; (b)<br />

contour plot <strong>of</strong> peak intensities as a function <strong>of</strong> reaction time. (c) XRD<br />

pattern for final FePO4 at the end <strong>of</strong> reaction.<br />

In collaboration with Pr<strong>of</strong>. Hong Li and his research<br />

group at Institute <strong>of</strong> Physics, Chinese Academy <strong>of</strong><br />

Sciences, a comparative study <strong>of</strong> the structural changes<br />

between LiMn 0.4 Fe 0.6 PO 4 cathode material samples with<br />

and without mesoporous structure during electrochemical<br />

cycling has been carried out using in situ and ex situ XRD<br />

(Figure V - 42). The phase transformation behaviours are<br />

quite different in these two samples. As shown in Figure V<br />

- 43, the structure <strong>of</strong> the mesoporou sample changed back<br />

to the original phase during first discharge with a high<br />

o<br />

*<br />

*<br />

(211)<br />

(a)<br />

(c)<br />

(131)<br />

(211)<br />

Energy Storage R &D 504 FY 2011 Annual Progress Report