V. Focused Fundamental Research - EERE - U.S. Department of ...

V. Focused Fundamental Research - EERE - U.S. Department of ...

V. Focused Fundamental Research - EERE - U.S. Department of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Vaughey – ANL<br />

V.C.7 Three-Dimensional Anode Architectures and Materials (ANL)<br />

Approach<br />

· Design new electrode architectures by<br />

electrodeposition techniques in which a Cu foam<br />

provides an electronically connected substrate onto<br />

which electrochemically active metals can be<br />

deposited.<br />

· Develop methods to build electrodes where copper<br />

metal acts as a binder and conductive additive for high<br />

capacity main group metals, e.g. silicon.<br />

· Develop characterization methods that allow for a<br />

better understanding <strong>of</strong> the electrochemically active<br />

interfaces with in the electrode architecture.<br />

been used a probe <strong>of</strong> the system on annealed laminates<br />

processed at various temperatures, Figure V - 96.<br />

Results<br />

The initial focus was to develop a method to encase<br />

micron-size Si particles with a Cu net or mesh formed in<br />

situ. The use <strong>of</strong> micron-size Si particles (10 to 20 μm)<br />

allows for lower surface area contact with the electrolyte,<br />

thus eliminating losses due to SEI formation and allowing<br />

for easier handling <strong>of</strong> the raw materials. Initial attention<br />

centered on generating a thin and dispersed Cu coating on<br />

the Si particles. After evaluating various methods, an<br />

electro-less deposition method was chosen for its<br />

simplicity and coating characteristics (see Figure V - 94).<br />

Figure V - 95: Demonstration <strong>of</strong> how silicon is bound to the copper foil<br />

(edge-on view) after annealing.<br />

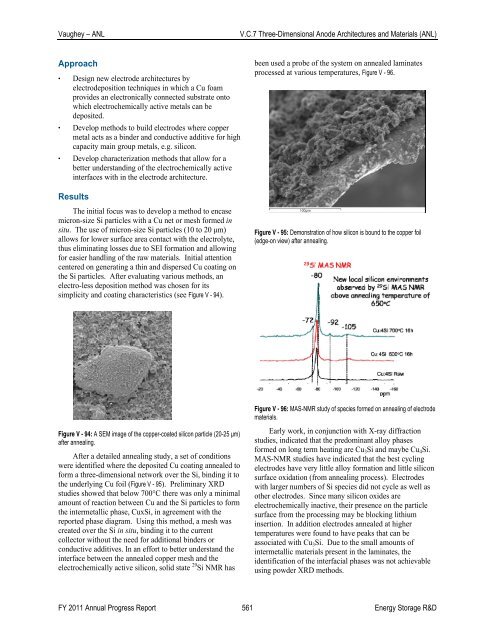

Figure V - 96: MAS-NMR study <strong>of</strong> species formed on annealing <strong>of</strong> electrode<br />

materials.<br />

Figure V - 94: A SEM image <strong>of</strong> the copper-coated silicon particle (20-25 μm)<br />

after annealing.<br />

After a detailed annealing study, a set <strong>of</strong> conditions<br />

were identified where the deposited Cu coating annealed to<br />

form a three-dimensional network over the Si, binding it to<br />

the underlying Cu foil (Figure V - 95). Preliminary XRD<br />

studies showed that below 700°C there was only a minimal<br />

amount <strong>of</strong> reaction between Cu and the Si particles to form<br />

the intermetallic phase, CuxSi, in agreement with the<br />

reported phase diagram. Using this method, a mesh was<br />

created over the Si in situ, binding it to the current<br />

collector without the need for additional binders or<br />

conductive additives. In an effort to better understand the<br />

interface between the annealed copper mesh and the<br />

electrochemically active silicon, solid state 29 Si NMR has<br />

Early work, in conjunction with X-ray diffraction<br />

studies, indicated that the predominant alloy phases<br />

formed on long term heating are Cu 3 Si and maybe Cu 4 Si.<br />

MAS-NMR studies have indicated that the best cycling<br />

electrodes have very little alloy formation and little silicon<br />

surface oxidation (from annealing process). Electrodes<br />

with larger numbers <strong>of</strong> Si species did not cycle as well as<br />

other electrodes. Since many silicon oxides are<br />

electrochemically inactive, their presence on the particle<br />

surface from the processing may be blocking lithium<br />

insertion. In addition electrodes annealed at higher<br />

temperatures were found to have peaks that can be<br />

associated with Cu 3 Si. Due to the small amounts <strong>of</strong><br />

intermetallic materials present in the laminates, the<br />

identification <strong>of</strong> the interfacial phases was not achievable<br />

using powder XRD methods.<br />

FY 2011 Annual Progress Report 561 Energy Storage R&D