Volume 2, Issue 1, 2011, Full Text - 5th International Conference on ...

Volume 2, Issue 1, 2011, Full Text - 5th International Conference on ...

Volume 2, Issue 1, 2011, Full Text - 5th International Conference on ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Day of Research 2010 – February 10 – Labo Soete, Ghent University, Belgium<br />

The final mixture was loaded into a cylindrical mold. Post-curing was carried out at a c<strong>on</strong>stant temperature<br />

of 180ºC by placing the samples in a preheated. This fricti<strong>on</strong> material is currently in development process to<br />

become a commercial brake pad for light vehicles by a manufacturer in Brazil.<br />

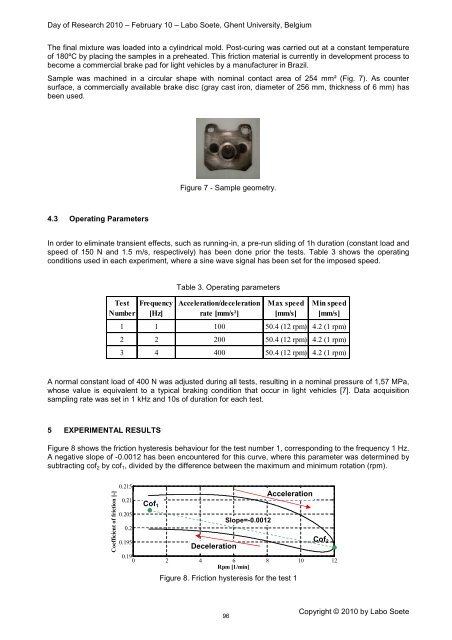

Sample was machined in a circular shape with nominal c<strong>on</strong>tact area of 254 mm² (Fig. 7). As counter<br />

surface, a commercially available brake disc (gray cast ir<strong>on</strong>, diameter of 256 mm, thickness of 6 mm) has<br />

been used.<br />

Figure 7 - Sample geometry.<br />

4.3 Operating Parameters<br />

In order to eliminate transient effects, such as running-in, a pre-run sliding of 1h durati<strong>on</strong> (c<strong>on</strong>stant load and<br />

speed of 150 N and 1.5 m/s, respectively) has been d<strong>on</strong>e prior the tests. Table 3 shows the operating<br />

c<strong>on</strong>diti<strong>on</strong>s used in each experiment, where a sine wave signal has been set for the imposed speed.<br />

Test<br />

Number<br />

Frequency<br />

[Hz]<br />

Table 3. Operating parameters<br />

Accelerati<strong>on</strong>/decelerati<strong>on</strong><br />

rate [mm/s²]<br />

Max speed<br />

[mm/s]<br />

Min speed<br />

[mm/s]<br />

1 1 100 50.4 (12 rpm) 4.2 (1 rpm)<br />

2 2 200 50.4 (12 rpm) 4.2 (1 rpm)<br />

3 4 400 50.4 (12 rpm) 4.2 (1 rpm)<br />

A normal c<strong>on</strong>stant load of 400 N was adjusted during all tests, resulting in a nominal pressure of 1,57 MPa,<br />

whose value is equivalent to a typical braking c<strong>on</strong>diti<strong>on</strong> that occur in light vehicles [7]. Data acquisiti<strong>on</strong><br />

sampling rate was set in 1 kHz and 10s of durati<strong>on</strong> for each test.<br />

5 EXPERIMENTAL RESULTS<br />

Figure 8 shows the fricti<strong>on</strong> hysteresis behaviour for the test number 1, corresp<strong>on</strong>ding to the frequency 1 Hz.<br />

A negative slope of -0.0012 has been encountered for this curve, where this parameter was determined by<br />

subtracting cof 2 by cof 1 , divided by the difference between the maximum and minimum rotati<strong>on</strong> (rpm).<br />

Coefficient of fricti<strong>on</strong> [-]<br />

0.215<br />

0.21<br />

0.205<br />

0.2<br />

0.195<br />

Cof 1<br />

Decelerati<strong>on</strong><br />

Slope=-0.0012<br />

Accelerati<strong>on</strong><br />

0.19<br />

0 2 4 6 8 10 12<br />

Rpm [1/min]<br />

Figure 8. Fricti<strong>on</strong> hysteresis for the test 1<br />

Cof 2<br />

96<br />

Copyright © 2010 by Labo Soete