Volume 2, Issue 1, 2011, Full Text - 5th International Conference on ...

Volume 2, Issue 1, 2011, Full Text - 5th International Conference on ...

Volume 2, Issue 1, 2011, Full Text - 5th International Conference on ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sustainable C<strong>on</strong>structi<strong>on</strong> and Design <str<strong>on</strong>g>2011</str<strong>on</strong>g><br />

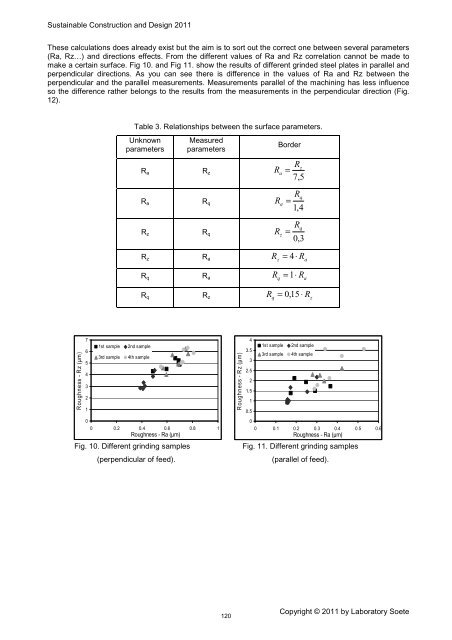

These calculati<strong>on</strong>s does already exist but the aim is to sort out the correct <strong>on</strong>e between several parameters<br />

(Ra, Rz…) and directi<strong>on</strong>s effects. From the different values of Ra and Rz correlati<strong>on</strong> cannot be made to<br />

make a certain surface. Fig 10. and Fig 11. show the results of different grinded steel plates in parallel and<br />

perpendicular directi<strong>on</strong>s. As you can see there is difference in the values of Ra and Rz between the<br />

perpendicular and the parallel measurements. Measurements parallel of the machining has less influence<br />

so the difference rather bel<strong>on</strong>gs to the results from the measurements in the perpendicular directi<strong>on</strong> (Fig.<br />

12).<br />

Table 3. Relati<strong>on</strong>ships between the surface parameters.<br />

Unknown<br />

parameters<br />

R a<br />

R a<br />

R z<br />

Measured<br />

parameters<br />

R z<br />

R q<br />

R q<br />

Border<br />

Rz<br />

R<br />

a<br />

=<br />

7,5<br />

Rq<br />

R<br />

a<br />

=<br />

1,4<br />

Rq<br />

R<br />

z<br />

=<br />

0,3<br />

= 4 ⋅ R<br />

R z R a z a<br />

R q R a q a<br />

R<br />

R<br />

= 1 ⋅ R<br />

= 0 , 15 ⋅ R<br />

R q R z q<br />

z<br />

R<br />

R oughness - R z (µm) a<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

1st sample<br />

3rd sample<br />

2nd sample<br />

4th sample<br />

0 0.2 0.4 0.6 0.8 1<br />

Roughness - Ra (µm)<br />

Fig. 10. Different grinding samples<br />

(perpendicular of feed).<br />

R oughness - R z (µm) a<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

1st sample<br />

3rd sample<br />

2nd sample<br />

4th sample<br />

0 0.1 0.2 0.3 0.4 0.5 0.6<br />

Roughness - Ra (µm)<br />

Fig. 11. Different grinding samples<br />

(parallel of feed).<br />

120<br />

Copyright © <str<strong>on</strong>g>2011</str<strong>on</strong>g> by Laboratory Soete