Competence.Work Parquet - 1926 Wood Flooring

Competence.Work Parquet - 1926 Wood Flooring

Competence.Work Parquet - 1926 Wood Flooring

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5<br />

PARKETT-HANDBUCH<br />

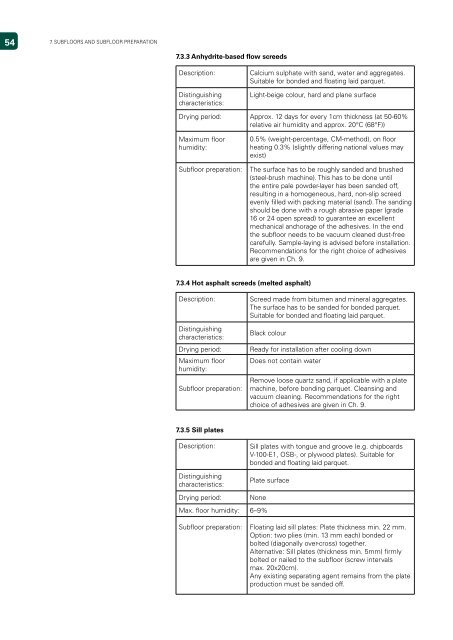

7. SUBFLOORS AND SUBFLOOR PREPARATION<br />

7. . Anhydrite-based flow screeds<br />

Description: Calcium sulphate with sand, water and aggregates.<br />

Suitable for bonded and floating laid parquet.<br />

Distinguishing<br />

characteristics:<br />

Light-beige colour, hard and plane surface<br />

Drying period: Approx. 12 days for every 1cm thickness (at 50-60%<br />

relative air humidity and approx. 20°C (68°F))<br />

Maximum floor<br />

humidity:<br />

0.5% (weight-percentage, CM-method), on floor<br />

heating 0.3% (slightly differing national values may<br />

exist)<br />

Subfloor preparation: The surface has to be roughly sanded and brushed<br />

(steel-brush machine). This has to be done until<br />

the entire pale powder-layer has been sanded off,<br />

resulting in a homogeneous, hard, non-slip screed<br />

evenly filled with packing material (sand). The sanding<br />

should be done with a rough abrasive paper (grade<br />

16 or 24 open spread) to guarantee an excellent<br />

mechanical anchorage of the adhesives. In the end<br />

the subfloor needs to be vacuum cleaned dust-free<br />

carefully. Sample-laying is advised before installation.<br />

Recommendations for the right choice of adhesives<br />

are given in Ch. 9.<br />

7. . Hot asphalt screeds (melted asphalt)<br />

Description: Screed made from bitumen and mineral aggregates.<br />

The surface has to be sanded for bonded parquet.<br />

Suitable for bonded and floating laid parquet.<br />

Distinguishing<br />

characteristics:<br />

Black colour<br />

Drying period: Ready for installation after cooling down<br />

Maximum floor<br />

humidity:<br />

Subfloor preparation:<br />

7. .5 Sill plates<br />

Does not contain water<br />

Remove loose quartz sand, if applicable with a plate<br />

machine, before bonding parquet. Cleansing and<br />

vacuum cleaning. Recommendations for the right<br />

choice of adhesives are given in Ch. 9.<br />

Description: Sill plates with tongue and groove (e.g. chipboards<br />

V-100-E1, OSB-, or plywood plates). Suitable for<br />

bonded and floating laid parquet.<br />

Distinguishing<br />

characteristics:<br />

Drying period: None<br />

Max. floor humidity: 6–9%<br />

Plate surface<br />

Subfloor preparation: Floating laid sill plates: Plate thickness min. 22 mm.<br />

Option: two plies (min. 13 mm each) bonded or<br />

bolted (diagonally over-cross) together.<br />

Alternative: Sill plates (thickness min. 5mm) firmly<br />

bolted or nailed to the subfloor (screw intervals<br />

max. 20x20cm).<br />

Any existing separating agent remains from the plate<br />

production must be sanded off.