Competence.Work Parquet - 1926 Wood Flooring

Competence.Work Parquet - 1926 Wood Flooring

Competence.Work Parquet - 1926 Wood Flooring

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

88<br />

PARKETT-HANDBUCH<br />

10. SURFACE TREATMENT<br />

– Application of the water-based Rustic Top-Oil using a roller or a rubber blade<br />

(approx. 0.02-0.05 l/m²).<br />

– The finished floor should be left to dry for at least 1-2 hours and not be<br />

walked on.<br />

– After the floor has been left to cure the parquet should be dry-polished in<br />

order to achieve a light silk-matt appearance and to protect the floor against<br />

dirt.<br />

Advantages of solvent-free systems<br />

• No contamination of the room’s air with solvents<br />

• Accessibility shortly after the finishing process.<br />

General advice<br />

– Careful: Oil-stained pads and other materials used during the application<br />

process must be dried on a non-flammable surface outside and left to cure or<br />

disposed of in a non-flammable container because of fire hazard.<br />

– In normal climatic conditions (18-24°C resp. 64-75°F and 40-60% air<br />

humidity) with sufficient ventilation the finished floor will need 24 - 48 hours<br />

until it can be loaded with heavy weights. In this time the floor should not<br />

be covered.<br />

– During the first few days or weeks one must pay particular attention to<br />

moisture coming in contact with the floor (danger of water stains).<br />

– All these recommendations refer to the mentioned materials, which are<br />

completely harmless once they are dry and have cured.<br />

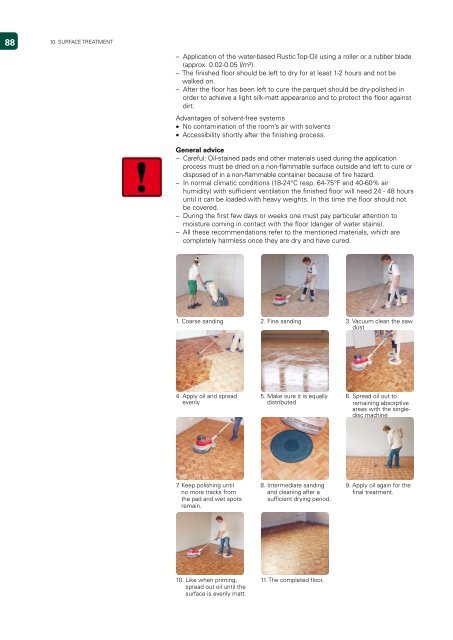

1. Coarse sanding 2. Fine sanding 3. Vacuum clean the saw<br />

dust<br />

4. Apply oil and spread<br />

evenly<br />

7. Keep polishing until<br />

no more tracks from<br />

the pad and wet spots<br />

remain.<br />

10. Like when priming,<br />

spread out oil until the<br />

surface is evenly matt.<br />

5. Make sure it is equally<br />

distributed<br />

8. Intermediate sanding<br />

and cleaning after a<br />

sufficient drying period.<br />

11. The completed floor.<br />

6. Spread oil out to<br />

remaining absorptive<br />

areas with the singledisc<br />

machine<br />

9. Apply oil again for the<br />

final treatment.