Master Thesis - Hochschule Bonn-Rhein-Sieg

Master Thesis - Hochschule Bonn-Rhein-Sieg

Master Thesis - Hochschule Bonn-Rhein-Sieg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2. Overview on human-robot <strong>Master</strong> <strong>Thesis</strong> Björn Ostermann page 10 of 126<br />

2 Overview on human-robot collaboration<br />

2.1 State of the art<br />

Since the invention of the joint arm robot in 1954 by George Devol, founder of the company<br />

Unimation, and its first usage in 1962 by General Motors [64], humans have been separated from<br />

industrial robots to assure their safety. Until the end of the 20 th century this separation was achieved by<br />

rigid fences.<br />

A major step towards a fenceless workplace was achieved in 1996, when the sourcecode SICK<br />

programmed for lasercannes was approved or safety related applications [60] by the BGIA, and later<br />

in 1998, when the first laser scanner, the PLS 101-312 by SICK, was approved for safety related<br />

applications [60] by the BGIA.<br />

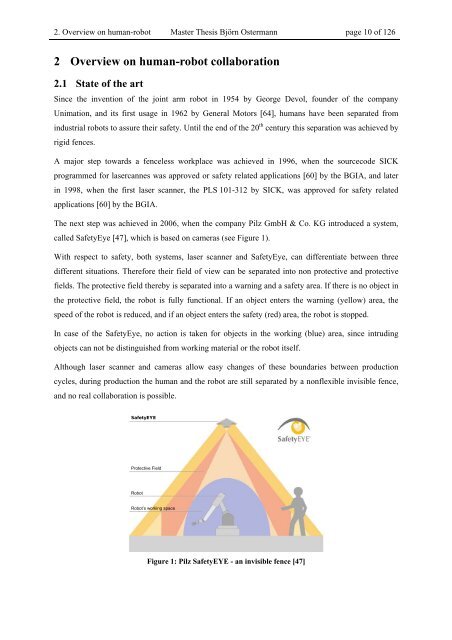

The next step was achieved in 2006, when the company Pilz GmbH & Co. KG introduced a system,<br />

called SafetyEye [47], which is based on cameras (see Figure 1).<br />

With respect to safety, both systems, laser scanner and SafetyEye, can differentiate between three<br />

different situations. Therefore their field of view can be separated into non protective and protective<br />

fields. The protective field thereby is separated into a warning and a safety area. If there is no object in<br />

the protective field, the robot is fully functional. If an object enters the warning (yellow) area, the<br />

speed of the robot is reduced, and if an object enters the safety (red) area, the robot is stopped.<br />

In case of the SafetyEye, no action is taken for objects in the working (blue) area, since intruding<br />

objects can not be distinguished from working material or the robot itself.<br />

Although laser scanner and cameras allow easy changes of these boundaries between production<br />

cycles, during production the human and the robot are still separated by a nonflexible invisible fence,<br />

and no real collaboration is possible.<br />

SafetyEYE<br />

Protective Field<br />

Robot<br />

Robot’s working space<br />

Figure 1: Pilz SafetyEYE - an invisible fence [47]