COUPLINGS

COUPLINGS

COUPLINGS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

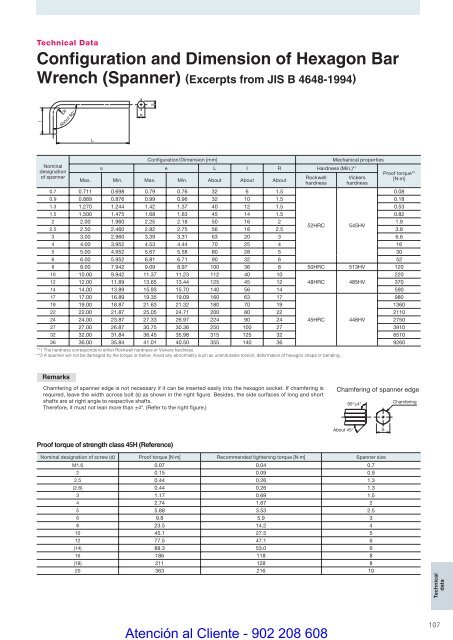

slTechnical DataConfiguration and Dimension of Hexagon BarWrench (Spanner) (Excerpts from JIS B 4648-1994)RAbout 90°eLConfi guration/Dimension [mm]Mechanical propertiesNominals e L I R Hardness (Min.)*designationProof torque* 2of spannerRockwell VickersMax. Min. Max. Min. About About About[N·m]hardness hardness0.7 0.711 0.698 0.79 0.76 32 6 1.50.080.9 0.889 0.876 0.99 0.96 32 10 1.5 0.181.3 1.270 1.244 1.42 1.37 40 12 1.5 0.531.5 1.500 1.475 1.68 1.63 45 14 1.5 0.822 2.00 1.960 2.25 2.18 50 16 2 1.952HRC 545HV2.5 2.50 2.460 2.82 2.75 56 18 2.5 3.83 3.00 2.960 3.39 3.31 63 20 3 6.64 4.00 3.952 4.53 4.44 70 25 4 165 5.00 4.952 5.67 5.58 80 28 5 306 6.00 5.952 6.81 6.71 90 32 6 528 8.00 7.942 9.09 8.97 100 36 8 50HRC 513HV 12010 10.00 9.942 11.37 11.23 112 40 1022012 12.00 11.89 13.65 13.44 125 45 12 48HRC 485HV37014 14.00 13.89 15.93 15.70 140 56 14 59017 17.00 16.89 19.35 19.09 160 63 1798019 19.00 18.87 21.63 21.32 180 70 19 136022 22.00 21.87 25.05 24.71 200 80 22 211024 24.00 23.87 27.33 26.97 224 90 24 45HRC 446HV275027 27.00 26.87 30.75 30.36 250 100 27 391032 32.00 31.84 36.45 35.98 315 125 32 651036 36.00 35.84 41.01 40.50 355 140 36 9260**1 The hardness corresponds to either Rockwell hardness or Vickers hardness.**2 A spanner will not be damaged by the torque or below. Avoid any abnormality such as unendurable torsion, deformation of hexagon shape or bending.RemarksChamfering of spanner edge is not necessary if it can be inserted easily into the hexagon socket. If chamfering isrequired, leave the width across bolt (s) as shown in the right fi gure. Besides, the side surfaces of long and shortshafts are at right angle to respective shafts.Therefore, it must not lean more than ±4°. (Refer to the right fi gure.)Chamfering of spanner edge90°±4°ChamferingAbout 45°SProof torque of strength class 45H (Reference)Nominal designation of screw (d) Proof torque [N·m] Recommended tightening torque [N·m] Spanner sizeM1.6 0.07 0.04 0.72 0.15 0.09 0.92.5 0.44 0.26 1.3(2.6) 0.44 0.26 1.33 1.17 0.69 1.54 2.74 1.67 25 5.88 3.53 2.56 9.8 5.9 38 23.5 14.2 410 45.1 27.5 512 77.5 47.1 6(14) 88.3 53.0 616 186 118 8(18) 211 128 820 363 216 10TechnicaldataAtención al Cliente - 902 208 608107