COUPLINGS

COUPLINGS

COUPLINGS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

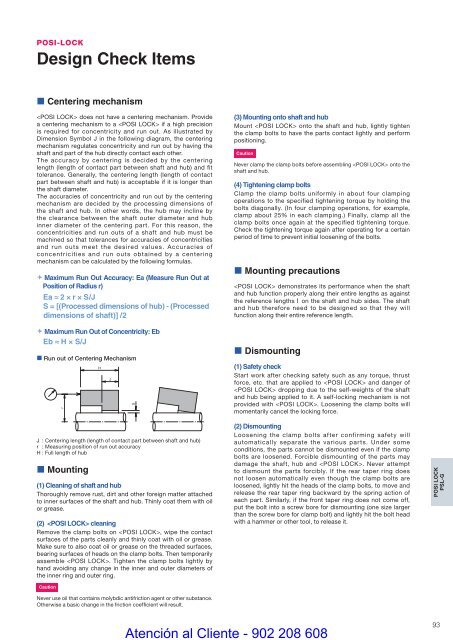

POSI-LOCKDesign Check Items• Centering mechanism does not have a centering mechanism. Providea centering mechanism to a if a high precisionis required for concentricity and run out. As illustrated byDimension Symbol J in the following diagram, the centeringmechanism regulates concentricity and run out by having theshaft and part of the hub directly contact each other.The accuracy by centering is decided by the centeringlength (length of contact part between shaft and hub) and fittolerance. Generally, the centering length (length of contactpart between shaft and hub) is acceptable if it is longer thanthe shaft diameter.The accuracies of concentricity and run out by the centeringmechanism are decided by the processing dimensions ofthe shaft and hub. In other words, the hub may incline bythe clearance between the shaft outer diameter and hubinner diameter of the centering part. For this reason, theconcentricities and run outs of a shaft and hub must bemachined so that tolerances for accuracies of concentricitiesand run outs meet the desired values. Accuracies ofconcentricities and run outs obtained by a centeringmechanism can be calculated by the following formulas. Maximum Run Out Accuracy: Ea (Measure Run Out atPosition of Radius r)Ea ≈ 2 × r × S/JS = [(Processed dimensions of hub) - (Processeddimensions of shaft)] /2(3) Mounting onto shaft and hubMount onto the shaft and hub, lightly tightenthe clamp bolts to have the parts contact lightly and performpositioning.CautionNever clamp the clamp bolts before assembling onto theshaft and hub.(4) Tightening clamp boltsClamp the clamp bolts uniformly in about four clampingoperations to the specified tightening torque by holding thebolts diagonally. (In four clamping operations, for example,clamp about 25% in each clamping.) Finally, clamp all theclamp bolts once again at the specified tightening torque.Check the tightening torque again after operating for a certainperiod of time to prevent initial loosening of the bolts.• Mounting precautions demonstrates its performance when the shaftand hub function properly along their entire lengths as againstthe reference lengths l on the shaft and hub sides. The shaftand hub therefore need to be designed so that they willfunction along their entire reference length. Maximum Run Out of Concentricity: EbEb ≈ H × S/J• Run out of Centering MechanismHJS• Dismounting(1) Safety checkStart work after checking safety such as any torque, thrustforce, etc. that are applied to and danger of dropping due to the self-weights of the shaftand hub being applied to it. A self-locking mechanism is notprovided with . Loosening the clamp bolts willmomentarily cancel the locking force.J : Centering length (length of contact part between shaft and hub)r : Measuring position of run out accuracyH : Full length of hub• Mounting(1) Cleaning of shaft and hubThoroughly remove rust, dirt and other foreign matter attachedto inner surfaces of the shaft and hub. Thinly coat them with oilor grease.(2) cleaningRemove the clamp bolts on , wipe the contactsurfaces of the parts cleanly and thinly coat with oil or grease.Make sure to also coat oil or grease on the threaded surfaces,bearing surfaces of heads on the clamp bolts. Then temporarilyassemble . Tighten the clamp bolts lightly byhand avoiding any change in the inner and outer diameters ofthe inner ring and outer ring.CautionNever use oil that contains molybdic antifriction agent or other substance.Otherwise a basic change in the friction coefficient will result.(2) DismountingLoosening the clamp bolts after confirming safety willautomatically separate the various parts. Under someconditions, the parts cannot be dismounted even if the clampbolts are loosened. Forcible dismounting of the parts maydamage the shaft, hub and . Never attemptto dismount the parts forcibly. If the rear taper ring doesnot loosen automatically even though the clamp bolts areloosened, lightly hit the heads of the clamp bolts, to move andrelease the rear taper ring backward by the spring action ofeach part. Similarly, if the front taper ring does not come off,put the bolt into a screw bore for dismounting (one size largerthan the screw bore for clamp bolt) and lightly hit the bolt headwith a hammer or other tool, to release it.POSI LOCKPSL-GAtención al Cliente - 902 208 60893