- Page 3 and 4: LNC-MILLTable of ContentTable of Co

- Page 5: LNC-MILLTable of ContentG131 Circul

- Page 9: LNC-MILLG-Code Function TableG Code

- Page 12 and 13: LNC-MILLG00 Rapid Positioning3 Comm

- Page 14 and 15: LNC-MILLG01 Linear InterpolationG01

- Page 16 and 17: LNC-MILLG02, G03 Circular/Helical I

- Page 18 and 19: LNC-MILLG04 DwellG04 DwellCommand F

- Page 20 and 21: LNC-MILLG10 Data Input SettingG10 D

- Page 22 and 23: LNC-MILLG15 Polar Coordinate Comman

- Page 24 and 25: LNC-MILLG17, G18, G19 Cutting Plane

- Page 26 and 27: LNC-MILLG22, G23 Tool Stored Stroke

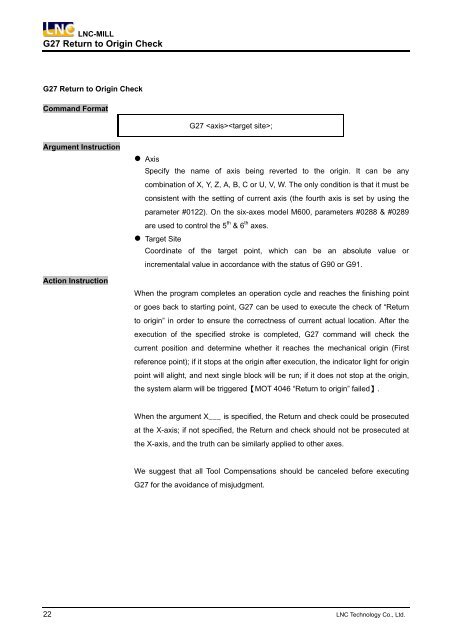

- Page 30 and 31: LNC-MILLG28 Return to the First Ref

- Page 32 and 33: LNC-MILLG29 Return from the First R

- Page 34 and 35: LNC-MILLG30 Auto Return to the 2nd,

- Page 36 and 37: LNC-MILLG31 Skip Signal Abort Block

- Page 38 and 39: LNC-MILLG31 Skip Signal Abort Block

- Page 40 and 41: LNC-MILLG41, G42 Tool Radius Compen

- Page 42 and 43: LNC-MILLG43, G44, G49 Tool Length C

- Page 44 and 45: LNC-MILLG43, G44, G49 Tool Length C

- Page 46 and 47: LNC-MILLG50, G51 Scaling CommandIll

- Page 48 and 49: LNC-MILLG52 Interval Coordinate Sys

- Page 50 and 51: LNC-MILLG54~G59 Manufacturing Coord

- Page 52 and 53: LNC-MILLG61, G64 Exact Positioning

- Page 54 and 55: LNC-MILLG65 Simple CallO0001;..#1==

- Page 56 and 57: LNC-MILLG66 Macro Program Mode Call

- Page 58 and 59: LNC-MILLG67 Macro Program Mode Call

- Page 60 and 61: 60°LNC-MILLG68, G69 Coordinate Sys

- Page 62 and 63: LNC-MILLG73 Rapid Peck Drilling Cyc

- Page 64 and 65: LNC-MILLG73 Rapid Peck Drilling Cyc

- Page 66 and 67: LNC-MILLG73 Rapid Peck Drilling Cyc

- Page 68 and 69: LNC-MILLG73 Rapid Peck Drilling Cyc

- Page 70 and 71: LNC-MILLG73 Rapid Peck Drilling Cyc

- Page 72 and 73: LNC-MILLG74 Left-Handed Screw Threa

- Page 74 and 75: LNC-MILLG74 Left-Handed Screw Threa

- Page 76 and 77: LNC-MILLG74 Left-Handed Screw Threa

- Page 78 and 79:

LNC-MILLG74 Left-Handed Screw Threa

- Page 80 and 81:

LNC-MILLG76 Fine Boring CycleG76 Fi

- Page 82 and 83:

LNC-MILLG76 Fine Boring CycleIllust

- Page 84 and 85:

LNC-MILLG76 Fine Boring CycleM03 S1

- Page 86 and 87:

LNC-MILLG76 Fine Boring CycleM03 S1

- Page 88 and 89:

LNC-MILLG76 Fine Boring CycleM03 S1

- Page 90 and 91:

LNC-MILLG81 Drilling CycleG81 Drill

- Page 92 and 93:

LNC-MILLG81 Drilling CycleProgram S

- Page 94 and 95:

LNC-MILLG81 Drilling CycleM03 S1000

- Page 96 and 97:

LNC-MILLG81 Drilling CycleM03 S1000

- Page 98 and 99:

LNC-MILLG82 Drilling CycleG82 Drill

- Page 100 and 101:

LNC-MILLG82 Drilling CycleProgram S

- Page 102 and 103:

LNC-MILLG82 Drilling CycleM03 S1000

- Page 104 and 105:

LNC-MILLG82 Drilling CycleM03 S1000

- Page 106 and 107:

LNC-MILLG83 Peck Drilling CycleG83

- Page 108 and 109:

LNC-MILLG83 Peck Drilling CycleProg

- Page 110 and 111:

LNC-MILLG83 Peck Drilling CycleM03

- Page 112 and 113:

LNC-MILLG83 Peck Drilling CycleM03

- Page 114 and 115:

LNC-MILLG84 Right-Handed Screw Thre

- Page 116 and 117:

LNC-MILLG84 Right-Handed Screw Thre

- Page 118 and 119:

LNC-MILLG84 Right-Handed Screw Thre

- Page 120 and 121:

LNC-MILLG84 Right-Handed Screw Thre

- Page 122 and 123:

LNC-MILLG85 Reaming CycleG85 Reamin

- Page 124 and 125:

LNC-MILLG85 Reaming CycleProgram Sa

- Page 126 and 127:

LNC-MILLG85 Reaming CycleM03 S1000;

- Page 128 and 129:

LNC-MILLG85 Reaming CycleM03 S1000;

- Page 130 and 131:

LNC-MILLG86 Boring CycleG86 Boring

- Page 132 and 133:

LNC-MILLG86 Boring CycleProgram Sam

- Page 134 and 135:

LNC-MILLG86 Boring CycleM03 S1000;G

- Page 136 and 137:

LNC-MILLG86 Boring CycleM03 S1000;G

- Page 138 and 139:

LNC-MILLG87 Back Boring/CuttingG87

- Page 140 and 141:

LNC-MILLG87 Back Boring/CuttingIllu

- Page 142 and 143:

LNC-MILLG87 Back Boring/CuttingM03

- Page 144 and 145:

LNC-MILLG87 Back Boring/CuttingM03

- Page 146 and 147:

LNC-MILLG88 Boring CycleG88 Boring

- Page 148 and 149:

LNC-MILLG88 Boring CycleProgram Sam

- Page 150 and 151:

LNC-MILLG88 Boring CycleM03 S1000;G

- Page 152 and 153:

LNC-MILLG88 Boring CycleM03 S1000;G

- Page 154 and 155:

LNC-MILLG89 Reaming CycleG89 Reamin

- Page 156 and 157:

LNC-MILLG89 Reaming CycleProgram Sa

- Page 158 and 159:

LNC-MILLG89 Reaming CycleM03 S1000;

- Page 160 and 161:

LNC-MILLG89 Reaming CycleM03 S1000;

- Page 162 and 163:

LNC-MILLG90, G91 Absolute, Incremen

- Page 164 and 165:

LNC-MILLG92 Coordinate SettingBNew

- Page 166 and 167:

LNC-MILLG98, G99 Retraction Point S

- Page 168 and 169:

LNC-MILLG101~G105 Compound G-Code f

- Page 170 and 171:

LNC-MILLG101 Linear Mode Multi-hole

- Page 172 and 173:

LNC-MILLG101 Linear Mode Multi-hole

- Page 174 and 175:

LNC-MILLG101 Linear Mode Multi-hole

- Page 176 and 177:

LNC-MILLG102 Circular Mode of Multi

- Page 178 and 179:

OLNC-MILLG102 Circular Mode of Mult

- Page 180 and 181:

LNC-MILLG102 Circular Mode of Multi

- Page 182 and 183:

LNC-MILLG102 Circular Mode of Multi

- Page 184 and 185:

LNC-MILLG103 Arc Mode of Multi-hole

- Page 186 and 187:

LNC-MILLG103 Arc Mode of Multi-hole

- Page 188 and 189:

LNC-MILLG103 Arc Mode of Multi-hole

- Page 190 and 191:

LNC-MILLG104 Grid Mode of Multi-hol

- Page 192 and 193:

LNC-MILLG104 Grid Mode of Multi-hol

- Page 194 and 195:

LNC-MILLG104 Grid Mode of Multi-hol

- Page 196 and 197:

LNC-MILLG104 Grid Mode of Multi-hol

- Page 198 and 199:

LNC-MILLG105 Promiscuous Mode of Mu

- Page 200 and 201:

LNC-MILLG105 Promiscuous Mode of Mu

- Page 202 and 203:

LNC-MILLG105 Promiscuous Mode of Mu

- Page 204 and 205:

LNC-MILLG105 Promiscuous Mode of Mu

- Page 206 and 207:

LNC-MILLG111 X-axis Two-Way Plane M

- Page 208 and 209:

LNC-MILLG112 Two-way Plane Processi

- Page 210 and 211:

LNC-MILLG113 One-way Plane Manufact

- Page 212 and 213:

LNC-MILLG114 Y One-way Plane Manufa

- Page 214 and 215:

LNC-MILLG121~G123 Compound G-Code f

- Page 216 and 217:

LNC-MILLG122 Rectangle Shape Side M

- Page 218 and 219:

LNC-MILLG131~G133 Compound G-Code f

- Page 220 and 221:

LNC-MILLG132 Rectangle Shape Fillet

- Page 223 and 224:

LNC MILLIndication of Auxiliary Fun

- Page 225:

LNC MILLIndication of Auxiliary Fun

- Page 228 and 229:

LNC MILLMACRO Program5.2 Macro Prog

- Page 230 and 231:

LNC MILLMACRO Program5.2.4 Calling

- Page 232 and 233:

LNC MILLMACRO Program5.2.5 Calling

- Page 234 and 235:

LNC MILLMACRO Program5.4 MACRO Func

- Page 236 and 237:

LNC MILLMACRO Program5.5.2 Classifi

- Page 238 and 239:

LNC MILLMACRO Program7. Coordinate

- Page 240 and 241:

LNC MILLMACRO ProgramTimesInstructi

- Page 242 and 243:

LNC MILLMACRO Program5.5.4 Tool Com

- Page 244 and 245:

LNC MILLMACRO Program5.5.7 Instruct

- Page 246 and 247:

LNC MILLMACRO Program5.8 Compare Co

- Page 248 and 249:

LNC MILLMACRO Program5.10 Flow Cont

- Page 250 and 251:

LNC MILLMACRO Program• DO cycle c

- Page 252:

LNC MILLMACRO Program#i=FIX(#j)(unc