2001 Annual Report - OneSteel

2001 Annual Report - OneSteel

2001 Annual Report - OneSteel

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

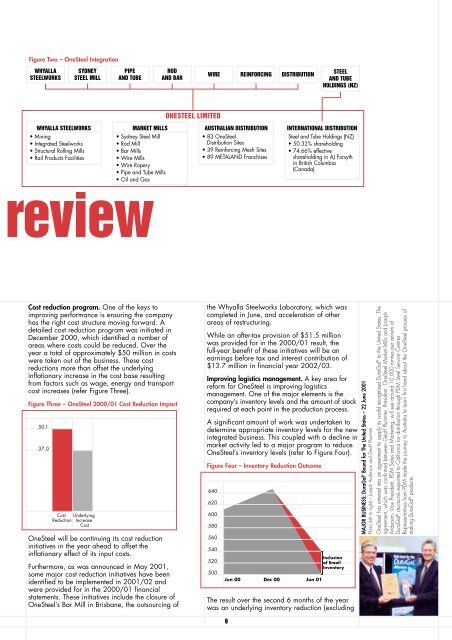

Figure Two – <strong>OneSteel</strong> IntegrationWHYALLASTEELWORKSSYDNEYSTEEL MILLPIPEAND TUBERODAND BARWIRE REINFORCING DISTRIBUTIONSTEELAND TUBEHOLDINGS (NZ)ONESTEEL LIMITEDWHYALLA STEELWORKS• Mining• Integrated Steelworks• Structural Rolling Mills• Rail Products FacilitiesMARKET MILLS• Sydney Steel Mill• Rod Mill• Bar Mills• Wire Mills• Wire Ropery• Pipe and Tube Mills• Oil and GasAUSTRALIAN DISTRIBUTION• 83 <strong>OneSteel</strong>Distribution Sites• 39 Reinforcing Mesh Sites• 89 METALAND FranchisesINTERNATIONAL DISTRIBUTIONSteel and Tube Holdings (NZ)• 50.32% shareholding• 74.66% effectiveshareholding in AJ Forsythin British Columbia(Canada)reviewCost reduction program. One of the keys toimproving performance is ensuring the companyhas the right cost structure moving forward. Adetailed cost reduction program was initiated inDecember 2000, which identified a number ofareas where costs could be reduced. Over theyear a total of approximately $50 million in costswere taken out of the business. These costreductions more than offset the underlyinginflationary increase in the cost base resultingfrom factors such as wage, energy and transportcost increases (refer Figure Three).Figure Three – <strong>OneSteel</strong> 2000/01 Cost Reduction Impact50.137.0Cost UnderlyingReduction IncreaseCost<strong>OneSteel</strong> will be continuing its cost reductioninitiatives in the year ahead to offset theinflationary effect of its input costs.Furthermore, as was announced in May <strong>2001</strong>,some major cost reduction initiatives have beenidentified to be implemented in <strong>2001</strong>/02 andwere provided for in the 2000/01 financialstatements. These initiatives include the closure of<strong>OneSteel</strong>’s Bar Mill in Brisbane, the outsourcing ofthe Whyalla Steelworks Laboratory, which wascompleted in June, and acceleration of otherareas of restructuring.While an after-tax provision of $51.5 millionwas provided for in the 2000/01 result, thefull-year benefit of these initiatives will be anearnings before tax and interest contribution of$13.7 million in financial year 2002/03.Improving logistics management. A key area forreform for <strong>OneSteel</strong> is improving logisticsmanagement. One of the major elements is thecompany’s inventory levels and the amount of stockrequired at each point in the production process.A significant amount of work was undertaken todetermine appropriate inventory levels for the newintegrated business. This coupled with a decline inmarket activity led to a major program to reduce<strong>OneSteel</strong>’s inventory levels (refer to Figure Four).Figure Four – Inventory Reduction Outcome640620600580560540520500Jun 00 Dec 00 Jun 01Inclusionof EmailInventoryThe result over the second 6 months of the yearwas an underlying inventory reduction (excludingMAJOR BUSINESS: DuraGal ® Bound for The United States – 22 June <strong>2001</strong>Photo (left to right) – Joseph Anderson and Geoff Plummer<strong>OneSteel</strong> has entered into an agreement to supply its world recognised DuraGal ® to the United States. Theagreement, which was confirmed between Geoff Plummer, President, <strong>OneSteel</strong> Market Mills and JosephAnderson, Vice President, PDM Sales and Marketing, will see around 10,000 tonnes per annum ofDuraGal ® structurals exported to California for distribution through PDM Steel Service Centres.Representatives from PDM made the journey to Australia to learn first hand about the <strong>OneSteel</strong> process ofmaking DuraGal ® products.9