2001 Annual Report - OneSteel

2001 Annual Report - OneSteel

2001 Annual Report - OneSteel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

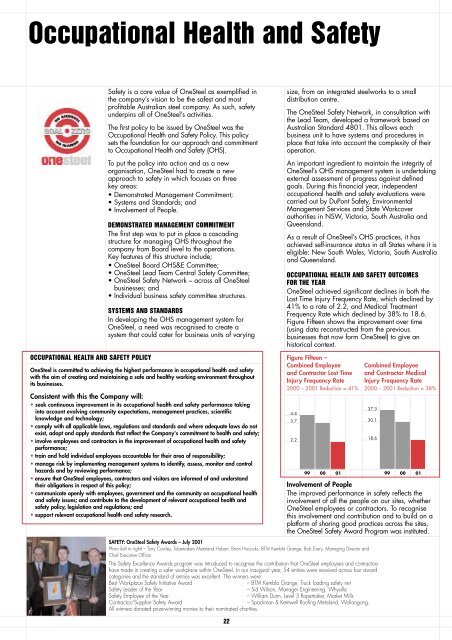

Occupational Health and SafetySafety is a core value of <strong>OneSteel</strong> as exemplified inthe company’s vision to be the safest and mostprofitable Australian steel company. As such, safetyunderpins all of <strong>OneSteel</strong>’s activities.The first policy to be issued by <strong>OneSteel</strong> was theOccupational Health and Safety Policy. This policysets the foundation for our approach and commitmentto Occupational Health and Safety (OHS).To put the policy into action and as a neworganisation, <strong>OneSteel</strong> had to create a newapproach to safety in which focuses on threekey areas:• Demonstrated Management Commitment;• Systems and Standards; and• Involvement of People.DEMONSTRATED MANAGEMENT COMMITMENTThe first step was to put in place a cascadingstructure for managing OHS throughout thecompany from Board level to the operations.Key features of this structure include;• <strong>OneSteel</strong> Board OHS&E Committee;• <strong>OneSteel</strong> Lead Team Central Safety Committee;• <strong>OneSteel</strong> Safety Network – across all <strong>OneSteel</strong>businesses; and• Individual business safety committee structures.SYSTEMS AND STANDARDSIn developing the OHS management system for<strong>OneSteel</strong>, a need was recognised to create asystem that could cater for business units of varyingsize, from an integrated steelworks to a smalldistribution centre.The <strong>OneSteel</strong> Safety Network, in consultation withthe Lead Team, developed a framework based onAustralian Standard 4801. This allows eachbusiness unit to have systems and procedures inplace that take into account the complexity of theiroperation.An important ingredient to maintain the integrity of<strong>OneSteel</strong>’s OHS management system is undertakingexternal assessment of progress against definedgoals. During this financial year, independentoccupational health and safety evaluations werecarried out by DuPont Safety, EnvironmentalManagement Services and State Workcoverauthorities in NSW, Victoria, South Australia andQueensland.As a result of <strong>OneSteel</strong>’s OHS practices, it hasachieved self-insurance status in all States where it iseligible: New South Wales, Victoria, South Australiaand Queensland.OCCUPATIONAL HEALTH AND SAFETY OUTCOMESFOR THE YEAR<strong>OneSteel</strong> achieved significant declines in both theLost Time Injury Frequency Rate, which declined by41% to a rate of 2.2, and Medical TreatmentFrequency Rate which declined by 38% to 18.6.Figure Fifteen shows the improvement over time(using data reconstructed from the previousbusinesses that now form <strong>OneSteel</strong>) to give anhistorical context.OCCUPATIONAL HEALTH AND SAFETY POLICY<strong>OneSteel</strong> is committed to achieving the highest performance in occupational health and safetywith the aim of creating and maintaining a safe and healthy working environment throughoutits businesses.Consistent with this the Company will:• seek continuous improvement in its occupational health and safety performance takinginto account evolving community expectations, management practices, scientificknowledge and technology;• comply with all applicable laws, regulations and standards and where adequate laws do notexist, adopt and apply standards that reflect the Company's commitment to health and safety;• involve employees and contractors in the improvement of occupational health and safetyperformance;• train and hold individual employees accountable for their area of responsibility;• manage risk by implementing management systems to identify, assess, monitor and controlhazards and by reviewing performance;• ensure that <strong>OneSteel</strong> employees, contractors and visitors are informed of and understandtheir obligations in respect of this policy;• communicate openly with employees, government and the community on occupational healthand safety issues; and contribute to the development of relevant occupational health andsafety policy, legislation and regulations; and• support relevant occupational health and safety research.SAFETY: <strong>OneSteel</strong> Safety Awards – July <strong>2001</strong>Photo (left to right) – Tony Cowley, Tubemakers Metaland Hobart; Brian Hiscocks, BTM Kembla Grange; Bob Every, Managing Director andChief Executive OfficerThe Safety Excellence Awards program was introduced to recognise the contribution that <strong>OneSteel</strong> employees and contractorshave made in creating a safer workplace within <strong>OneSteel</strong>. In our inaugural year, 54 entries were received across four awardcategories and the standard of entries was excellent. The winners were:Best Workplace Safety Initiative Award– BTM Kembla Grange, Truck loading safety netSafety Leader of the Year– Sid Wilson, Manager Engineering, WhyallaSafety Employee of the Year– William Dunn, Level 3 Ropemaker, Market MillsContractor/Supplier Safety Award– Spackman & Kentwell Roofing Metaland, Wollongong.All winners donated prize-winning monies to their nominated charities.22Figure Fifteen –Combined Employee Combined Employeeand Contractor Lost Time and Contractor MedicalInjury Frequency Rate Injury Frequency Rate2000 – <strong>2001</strong> Reduction = 41% 2000 – <strong>2001</strong> Reduction = 38%4.43.72.299 00 0137.330.118.699 00 01Involvement of PeopleThe improved performance in safety reflects theinvolvement of all the people on our sites, whether<strong>OneSteel</strong> employees or contractors. To recognisethis involvement and contribution and to build on aplatform of sharing good practices across the sites,the <strong>OneSteel</strong> Safety Award Program was instituted.