PNEG-1156ETL - David Manufacturing Co.

PNEG-1156ETL - David Manufacturing Co.

PNEG-1156ETL - David Manufacturing Co.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

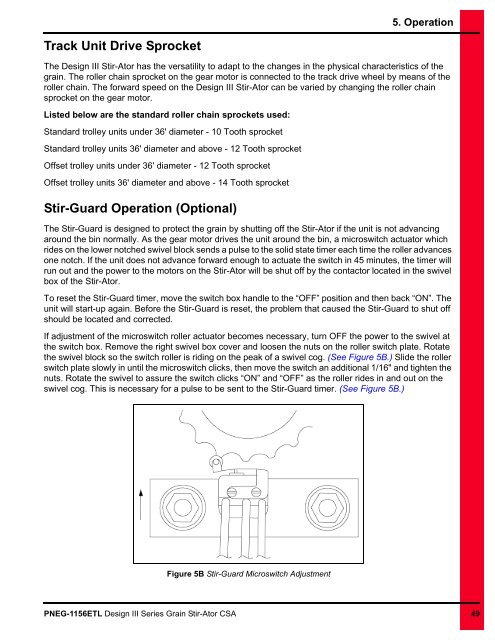

5. OperationTrack Unit Drive SprocketThe Design III Stir-Ator has the versatility to adapt to the changes in the physical characteristics of thegrain. The roller chain sprocket on the gear motor is connected to the track drive wheel by means of theroller chain. The forward speed on the Design III Stir-Ator can be varied by changing the roller chainsprocket on the gear motor.Listed below are the standard roller chain sprockets used:Standard trolley units under 36' diameter - 10 Tooth sprocketStandard trolley units 36' diameter and above - 12 Tooth sprocketOffset trolley units under 36' diameter - 12 Tooth sprocketOffset trolley units 36' diameter and above - 14 Tooth sprocketStir-Guard Operation (Optional)The Stir-Guard is designed to protect the grain by shutting off the Stir-Ator if the unit is not advancingaround the bin normally. As the gear motor drives the unit around the bin, a microswitch actuator whichrides on the lower notched swivel block sends a pulse to the solid state timer each time the roller advancesone notch. If the unit does not advance forward enough to actuate the switch in 45 minutes, the timer willrun out and the power to the motors on the Stir-Ator will be shut off by the contactor located in the swivelbox of the Stir-Ator.To reset the Stir-Guard timer, move the switch box handle to the “OFF” position and then back “ON”. Theunit will start-up again. Before the Stir-Guard is reset, the problem that caused the Stir-Guard to shut offshould be located and corrected.If adjustment of the microswitch roller actuator becomes necessary, turn OFF the power to the swivel atthe switch box. Remove the right swivel box cover and loosen the nuts on the roller switch plate. Rotatethe swivel block so the switch roller is riding on the peak of a swivel cog. (See Figure 5B.) Slide the rollerswitch plate slowly in until the microswitch clicks, then move the switch an additional 1/16" and tighten thenuts. Rotate the swivel to assure the switch clicks “ON” and “OFF” as the roller rides in and out on theswivel cog. This is necessary for a pulse to be sent to the Stir-Guard timer. (See Figure 5B.)Figure 5B Stir-Guard Microswitch Adjustment<strong>PNEG</strong>-<strong>1156ETL</strong> Design III Series Grain Stir-Ator CSA 49