PNEG-1156ETL - David Manufacturing Co.

PNEG-1156ETL - David Manufacturing Co.

PNEG-1156ETL - David Manufacturing Co.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

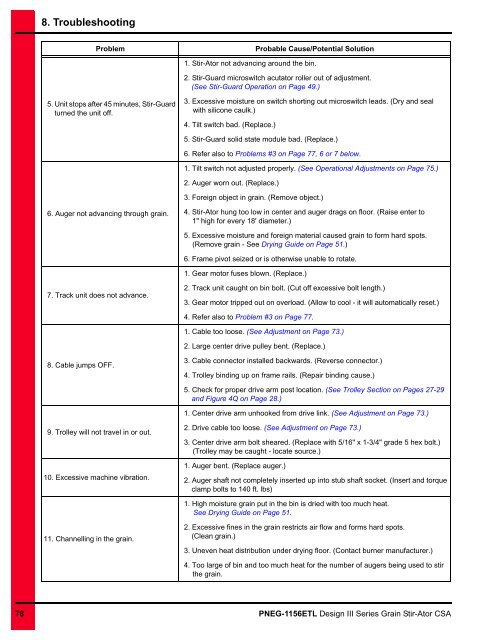

8. TroubleshootingProblemProbable Cause/Potential Solution1. Stir-Ator not advancing around the bin.2. Stir-Guard microswitch acutator roller out of adjustment.(See Stir-Guard Operation on Page 49.)5. Unit stops after 45 minutes, Stir-Guardturned the unit off.3. Excessive moisture on switch shorting out microswitch leads. (Dry and sealwith silicone caulk.)4. Tilt switch bad. (Replace.)5. Stir-Guard solid state module bad. (Replace.)6. Refer also to Problems #3 on Page 77, 6 or 7 below.1. Tilt switch not adjusted properly. (See Operational Adjustments on Page 75.)2. Auger worn out. (Replace.)3. Foreign object in grain. (Remove object.)6. Auger not advancing through grain.4. Stir-Ator hung too low in center and auger drags on floor. (Raise enter to1" high for every 18' diameter.)5. Excessive moisture and foreign material caused grain to form hard spots.(Remove grain - See Drying Guide on Page 51.)6. Frame pivot seized or is otherwise unable to rotate.1. Gear motor fuses blown. (Replace.)7. Track unit does not advance.2. Track unit caught on bin bolt. (Cut off excessive bolt length.)3. Gear motor tripped out on overload. (Allow to cool - it will automatically reset.)4. Refer also to Problem #3 on Page 77.1. Cable too loose. (See Adjustment on Page 73.)2. Large center drive pulley bent. (Replace.)8. Cable jumps OFF.3. Cable connector installed backwards. (Reverse connector.)4. Trolley binding up on frame rails. (Repair binding cause.)5. Check for proper drive arm post location. (See Trolley Section on Pages 27-29and Figure 4Q on Page 28.)1. Center drive arm unhooked from drive link. (See Adjustment on Page 73.)9. Trolley will not travel in or out.10. Excessive machine vibration.2. Drive cable too loose. (See Adjustment on Page 73.)3. Center drive arm bolt sheared. (Replace with 5/16" x 1-3/4" grade 5 hex bolt.)(Trolley may be caught - locate source.)1. Auger bent. (Replace auger.)2. Auger shaft not completely inserted up into stub shaft socket. (Insert and torqueclamp bolts to 140 ft. lbs)1. High moisture grain put in the bin is dried with too much heat.See Drying Guide on Page 51.11. Channelling in the grain.2. Excessive fines in the grain restricts air flow and forms hard spots.(Clean grain.)3. Uneven heat distribution under drying floor. (<strong>Co</strong>ntact burner manufacturer.)4. Too large of bin and too much heat for the number of augers being used to stirthe grain.78 <strong>PNEG</strong>-<strong>1156ETL</strong> Design III Series Grain Stir-Ator CSA