- Page 1:

Cervical Cancer PreventionGuideline

- Page 5:

TABLE OF CONTENTSPREFACE AND ACKNOW

- Page 8:

How to High-Level Disinfect Surgica

- Page 11 and 12:

Table C-2Figure C-1Preparing a Dilu

- Page 13 and 14:

PREFACE AND ACKNOWLEDGMENTSThis ref

- Page 15 and 16:

ONEINTRODUCTIONMAGNITUDE OF THE PRO

- Page 17 and 18:

IntroductionFigure 1-3. Incidence o

- Page 19 and 20:

Introductionprevalence areas, a sta

- Page 21 and 22:

Table 1-2. Reduction in Cumulative

- Page 23 and 24:

Introductiontheir performance was t

- Page 25 and 26:

Introductionlesions, or a false pos

- Page 27 and 28:

IntroductionCompared to other metho

- Page 29 and 30:

Introductionsignificantly to women

- Page 31 and 32:

IntroductionBelinson JL et al. 2001

- Page 33 and 34:

IntroductionMitchell MF et al. 1998

- Page 35 and 36:

IntroductionYlitalo N et al. 1999.

- Page 37 and 38:

TWOHUMAN PAPILLOMAVIRUS AND CERVICA

- Page 39 and 40:

Human Papillomavirus and Cervical C

- Page 41 and 42:

Human Papillomavirus and Cervical C

- Page 43 and 44:

Human Papillomavirus and Cervical C

- Page 45 and 46:

Human Papillomavirus and Cervical C

- Page 47 and 48:

THREEPATHOPHYSIOLOGY OF CERVICAL CA

- Page 49 and 50:

With the onset of puberty, whichis

- Page 51 and 52:

Pathophysiology of Cervical Cancerp

- Page 53 and 54:

Pathophysiology of Cervical CancerP

- Page 55 and 56:

Pathophysiology of Cervical CancerI

- Page 57 and 58:

Pathophysiology of Cervical CancerR

- Page 59 and 60:

FOURTALKING WITH WOMEN ABOUTCERVICA

- Page 61 and 62:

Talking with Women About Cervical C

- Page 63 and 64:

Talking with Women About Cervical C

- Page 65 and 66:

Talking with Women About Cervical C

- Page 67 and 68:

Talking with Women About Cervical C

- Page 69 and 70:

FIVEPREVENTING INFECTIONS INHEALTHC

- Page 71 and 72:

Preventing Infections in Healthcare

- Page 73 and 74:

Preventing Infections in Healthcare

- Page 75 and 76:

Preventing Infections in Healthcare

- Page 77 and 78:

Preventing Infections in Healthcare

- Page 79 and 80:

SIXCLIENT ASSESSMENT AND VIA TESTIN

- Page 81 and 82:

Client Assessment and VIA TestingFi

- Page 83 and 84:

Client Assessment and VIA TestingIN

- Page 85 and 86:

Client Assessment and VIA Testingst

- Page 87 and 88:

Client Assessment and VIA Testingsp

- Page 89 and 90:

Client Assessment and VIA Testingth

- Page 91 and 92:

SEVENTREATMENT AND FOLLOWUPBACKGROU

- Page 93 and 94:

Treatment and Followupregardless of

- Page 95 and 96:

Treatment and FollowupFigure 7-1. L

- Page 97 and 98:

Treatment and FollowupTable 7-6. Co

- Page 99 and 100: Treatment and FollowupFigure 7-2 is

- Page 101 and 102: Treatment and Followup• Regulator

- Page 103 and 104: Treatment and FollowupCRYOTHERAPY P

- Page 105 and 106: Treatment and FollowupStep 6 Point

- Page 107 and 108: Treatment and FollowupNote: When CO

- Page 109 and 110: Treatment and FollowupStep 5Advise

- Page 111 and 112: Treatment and FollowupBerget A, B A

- Page 113 and 114: APPENDIX ATESTS FOR CERVICAL CANCER

- Page 115 and 116: Tests for Cervical Cancer Screening

- Page 117 and 118: Tests for Cervical Cancer Screening

- Page 119 and 120: Tests for Cervical Cancer Screening

- Page 121 and 122: APPENDIX BSCREENING TEST QUALITIES

- Page 123 and 124: Screening Test Qualities and Their

- Page 125 and 126: APPENDIX CINFECTION PREVENTION PROC

- Page 127 and 128: Infection Prevention Processesfor m

- Page 129 and 130: Infection Prevention Processeswith

- Page 131 and 132: Infection Prevention ProcessesFigur

- Page 133 and 134: Table C-4. Preparing and Using Chem

- Page 135 and 136: Infection Prevention ProcessesStora

- Page 137 and 138: Infection Prevention Processes• h

- Page 139 and 140: APPENDIX DTECHNICAL OVERVIEW OF THE

- Page 141 and 142: Technical Overview of the Cryothera

- Page 143 and 144: Figure D-5. Removing Protector Tube

- Page 145 and 146: Technical Overview of the Cryothera

- Page 147 and 148: Figure D-11. Gas Cylinder Secured t

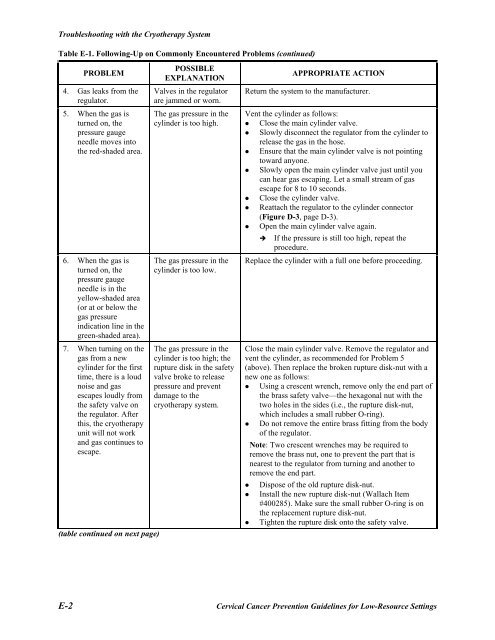

- Page 149: APPENDIX ETROUBLESHOOTING WITH THEC

- Page 153 and 154: APPENDIX FPROCESSING SURGICAL GLOVE

- Page 155 and 156: Processing Surgical GlovesTable F-1

- Page 157 and 158: Processing Surgical GlovesSTEP 10:

- Page 159 and 160: APPENDIX GPERFORMING BREAST AND PEL

- Page 161 and 162: Performing Breast and Pelvic Examin

- Page 163 and 164: Figure G-2. Breast Puckering or Dim

- Page 165 and 166: Figure G-5. Checking for Nipple Dis

- Page 167 and 168: Performing Breast and Pelvic Examin

- Page 169 and 170: Performing Breast and Pelvic Examin

- Page 171 and 172: Performing Breast and Pelvic Examin

- Page 173 and 174: Performing Breast and Pelvic Examin

- Page 175 and 176: Performing Breast and Pelvic Examin

- Page 177 and 178: Performing Breast and Pelvic Examin

- Page 179 and 180: Performing Breast and Pelvic Examin

- Page 181 and 182: Figure G-18. Speculum in Place with

- Page 183 and 184: Performing Breast and Pelvic Examin

- Page 185 and 186: Performing Breast and Pelvic Examin

- Page 187 and 188: Performing Breast and Pelvic Examin

- Page 189 and 190: Performing Breast and Pelvic Examin

- Page 191 and 192: Performing Breast and Pelvic Examin

- Page 193 and 194: Performing Breast and Pelvic Examin

- Page 195 and 196: Performing Breast and Pelvic Examin

- Page 197 and 198: Performing Breast and Pelvic Examin

- Page 199 and 200: Performing Breast and Pelvic Examin

- Page 201 and 202:

Performing Breast and Pelvic Examin

- Page 203 and 204:

Performing Breast and Pelvic Examin

- Page 205 and 206:

APPENDIX HPERCEIVED BARRIERS TO PRO

- Page 207 and 208:

AVAILABILITY OF BASIC SUPPLIES AND

- Page 209 and 210:

GLOSSARYAcetic AcidAcetowhite Chang

- Page 211 and 212:

PatulousSquamocolumnarJunction (SCJ

- Page 213 and 214:

ADDITIONAL READINGAlliance for Cerv

- Page 216:

innovating to save liveswww.jhpiego