Manual - Unvented Gas Log Heater or Vented Decorative Appliance

Manual - Unvented Gas Log Heater or Vented Decorative Appliance

Manual - Unvented Gas Log Heater or Vented Decorative Appliance

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

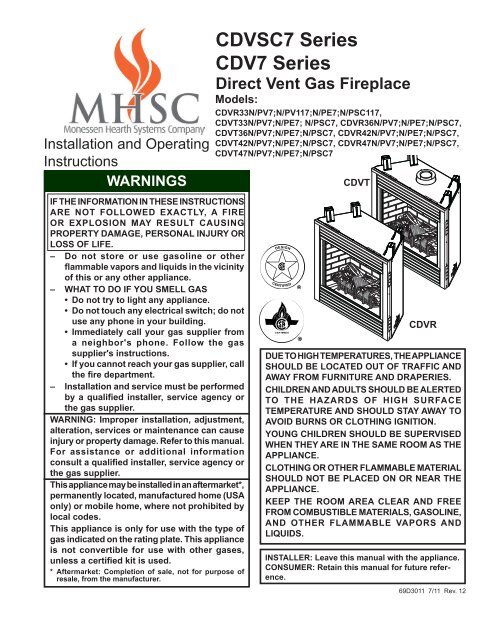

Installation and OperatingInstructionsWARNINGSIf the inf<strong>or</strong>mation in these instructionsare not followed exactly, a fire<strong>or</strong> explosion may result causingproperty damage, personal injury <strong>or</strong>loss of life.– Do not st<strong>or</strong>e <strong>or</strong> use gasoline <strong>or</strong> otherflammable vap<strong>or</strong>s and liquids in the vicinityof this <strong>or</strong> any other appliance.– WHAT TO DO IF YOU SMELL GAS• Do not try to light any appliance.• Do not touch any electrical switch; do notuse any phone in your building.• Immediately call your gas supplier froma neighb<strong>or</strong>'s phone. Follow the gassupplier's instructions.• If you cannot reach your gas supplier, callthe fire department.– Installation and service must be perf<strong>or</strong>medby a qualified installer, service agency <strong>or</strong>the gas supplier.WARNING: Improper installation, adjustment,alteration, services <strong>or</strong> maintenance can causeinjury <strong>or</strong> property damage. Refer to this manual.F<strong>or</strong> assistance <strong>or</strong> additional inf<strong>or</strong>mationconsult a qualified installer, service agency <strong>or</strong>the gas supplier.This appliance may be installed in an aftermarket*,permanently located, manufactured home (USAonly) <strong>or</strong> mobile home, where not prohibited bylocal codes.This appliance is only f<strong>or</strong> use with the type ofgas indicated on the rating plate. This applianceis not convertible f<strong>or</strong> use with other gases,unless a certified kit is used.* Aftermarket: Completion of sale, not f<strong>or</strong> purpose ofresale, from the manufacturer.CDVSC7 SeriesCDV7 SeriesDirect Vent <strong>Gas</strong> FireplaceModels:CDVR33n/pv7;N/PV117;n/pe7;N/PSC117,CDVT33n/Pv7;n/pe7; N/PSC7, CDVR36n/pv7;n/pe7;N/PSC7,CDVT36n/Pv7;n/pe7;N/PSC7, CDVR42n/pv7;n/pe7;N/PSC7,CDVT42n/Pv7;n/pe7;N/PSC7, CDVR47n/pv7;n/pe7;N/PSC7,CDVT47n/Pv7;n/pe7;N/PSC7CDVTCDVRDUE TO HIGH TEMPERATURES, THE APPLIANCESHOULD BE LOCATED OUT OF TRAFFIC ANDAWAY FROM FURNITURE AND DRAPERIES.CHILDREN AND ADULTS 693011 SHOULD BE ALERTEDTO THE HAZARDS CDVRT7 OF HIGH cover SURFACETEMPERATURE AND SHOULD STAY AWAY TOAVOID BURNS OR CLOTHING IGNITION.YOUNG CHILDREN SHOULD BE SUPERVISEDWHEN THEY ARE IN THE SAME ROOM AS THEAPPLIANCE.CLOTHING OR OTHER FLAMMABLE MATERIALSHOULD NOT BE PLACED ON OR NEAR THEAPPLIANCE.Keep the room area clear and freefrom combustible materials, gasoline,and other flammable vap<strong>or</strong>s andliquids.INSTALLER: Leave this manual with the appliance.CONSUMER: Retain this manual f<strong>or</strong> future reference.69D3011 7/11 Rev. 12

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceCONTENTSPLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE.Thank you and congratulations on your purchase of a MHSC fireplace.IMPORTANT: Read all instructions and warnings carefully bef<strong>or</strong>e starting installation.Failure to follow these instructions fully may result in a possible fire hazard and will void the warranty.Imp<strong>or</strong>tant Safety Inf<strong>or</strong>mation..................................... 3Code Approval............................................................. 4Product Specifications............................................... 5High Elevations....................................................... 6<strong>Gas</strong> Pressures........................................................ 6<strong>Gas</strong> Specifications, Orifice Sizes............................ 6Fireplace & Framing Dimensions........................... 7Pre-Installation Inf<strong>or</strong>mationBef<strong>or</strong>e You Start..................................................... 9Fireplace Framing .................................................. 9Fireplace Location................................................ 10Clearances..................................................................11Securing Fireplace to Flo<strong>or</strong> <strong>or</strong> Framing.................. 12Finishing Material................................................. 12Venting Installation................................................... 13General VentingTermination Location...................................... 13Termination Clearances................................. 15Assembling Vent Pipes.................................. 15Rear Vent Installation Only............................. 16How to Use the Vent Graph........................... 17Vent Pipe Clearances..................................... 18Rear Vent Applications & Installation.................... 19Top Vent Sidewall Applications & Installation....... 20Vertical Sidewall Applications & Installation.......... 22Below Grade Installation....................................... 24Vertical Through-the-RoofApplications & Installation.............................. 25Fireplace Installation................................................ 27Check <strong>Gas</strong> Type................................................... 27<strong>Gas</strong> Pipe Installation............................................. 28Check <strong>Gas</strong> Pressure - Millivolt................................ 29Electrical Installation................................................ 29Electrical Wiring................................................. 29Remote Wall Mounted Switch............................... 30Remote Wall Switch.............................................. 30Optional DC Remote Systems.............................. 30Electronic Pilot Ignition Wiring.............................. 31Optional Fan/Blower Systems.............................. 31Operating Instructions - Millivolt............................. 32What To Do If You Smell <strong>Gas</strong>............................... 32Lighting Pilot f<strong>or</strong> the First Time............................. 32Lighting Pilot......................................................... 33Lighting Burner..................................................... 34To Turn Off <strong>Gas</strong>.................................................... 34Operating Instructions Electronic Ignition............. 35What To Do If You Smell <strong>Gas</strong>............................... 35Lighting Electronic Ignition.................................... 35To Turn Off <strong>Gas</strong>.................................................... 35Check <strong>Gas</strong> Pressure - Signature Command System 36Electrical Installation - SCS..................................... 36Electrical Wiring.................................................... 36Junction Box Wiring.............................................. 37Command Center Wall Installation....................... 37Wall Switch Installation......................................... 37Signature Command System Wiring Diagram...... 38Optional Fan/Blower System - SCS......................... 39BLOTSC Wiring Diagram..................................... 39BLOT Automotic Thermostat Blower.................... 40FK-12 <strong>Manual</strong> Blower........................................... 40Operating Instructions - SCS................................... 41What To Do If You Smell <strong>Gas</strong>............................... 41Operating Instructions.......................................... 42To Turn Off <strong>Gas</strong>.................................................... 42Signature Command System................................... 43Operation Instructions.......................................... 43Glass Removal.......................................................... 46<strong>Log</strong> Placement.......................................................... 46Rockwool Placement............................................ 46<strong>Log</strong> Placement...................................................... 47Lava Rock and Ember Placement........................ 47Cleaning and Maintenance....................................... 48Burner, Pilot and Control Compartment................ 48Pilot Flame............................................................ 48Burner Flame........................................................ 48Vent System......................................................... 49Glass Do<strong>or</strong>............................................................ 49<strong>Log</strong>s...................................................................... 49Rock Wool ........................................................... 49Troubleshooting........................................................ 50Replacement Parts.................................................... 54Firebox Components............................................ 54Standing Pilot - Millivolt Control............................ 56Electronic Ignition................................................. 58Signature Command System................................ 59<strong>Log</strong>s...................................................................... 61Venting Components............................................ 62Massachusetts Requirements................................. 66Warranty..................................................................... 67Energuide Efficiencies............................................. 6869D3011

IMPORTANT SAFETY INFORMATIONINSTALLERPlease leave these instructions with the appliance.OWNERCDVSC7 & CDV7 Series <strong>Gas</strong> FireplacePlease retain these instructions f<strong>or</strong> future reference.WARNING• Read this owner’s manual carefully and completely bef<strong>or</strong>e trying to assemble, operate,<strong>or</strong> service this fireplace.• Any change to this fireplace <strong>or</strong> its controls can be dangerous.• Improper installation <strong>or</strong> use of this fireplace can cause serious injury <strong>or</strong> death fromfire, burns, explosions, electrical shock and carbon monoxide poisoning.This fireplace is a vented product. This fireplace mustbe properly installed by a qualified service person. Theglass do<strong>or</strong> must be properly seated and sealed. If thisunit is not properly installed by a qualified service personwith glass do<strong>or</strong> properly seated and sealed, combustionleakage can occur.CARBON MONOXIDE POISONING: Early signs ofcarbon monoxide poisoning are similar to the flu withheadaches, dizziness and/<strong>or</strong> nausea. If you have thesesigns, the fireplace may not have been installed properly.Get fresh air at once! Have the fireplace inspected andserviced by a qualified service person. Some people arem<strong>or</strong>e affected by carbon monoxide than others. Theseinclude pregnant women, people with heart <strong>or</strong> lung disease<strong>or</strong> anemia, those under the influence of alcohol, andthose at high altitudes.Propane/LP gas and natural gas are both od<strong>or</strong>less. Anod<strong>or</strong>-making agent is added to each of these gases. Theod<strong>or</strong> helps you detect a gas leak. However, the od<strong>or</strong>added to these gases can fade. <strong>Gas</strong> may be present eventhough no od<strong>or</strong> exists.Make certain you read and understand all warnings. Keepthis manual f<strong>or</strong> reference. It is your guide to safe andproper operation of this fireplace.1. This appliance is only f<strong>or</strong> use with the type of gasindicated on the rating plate. This appliance is notconvertible f<strong>or</strong> use with other gases unless a certifiedkit is used.2. F<strong>or</strong> propane/LP fireplace, do not place propane/LPsupply tank(s) inside any structure. Locate propane/LP supply tank(s) outdo<strong>or</strong>s. To prevent perf<strong>or</strong>manceproblems, do not use propane/LP fuel tank of lessthan 100 lbs. capacity.3. If you smell gas• shut off gas supply.• do not try to light any appliance.• do not touch any electrical switch; do not use anyphone in your building .• immediately call your gas supplier from a neighb<strong>or</strong>’sphone. Follow the gas supplier’s instructions.69D30114. Never install the fireplace• in a recreational vehicle• where curtains, furniture, clothing, <strong>or</strong> other flammableobjects are less than 42" from the front, top,<strong>or</strong> sides of the fireplace• in high traffic areas• in windy <strong>or</strong> drafty areas5. This fireplace reaches high temperatures. Keep childrenand adults away from hot surfaces to avoid burns <strong>or</strong>clothing ignition. Fireplace will remain hot f<strong>or</strong> a time aftershutdown. Allow surfaces to cool bef<strong>or</strong>e touching.6. Young children should be carefully supervised whenthey are in the same room as the appliance. Toddlers,young children and others may be susceptible to accidentalcontact burns. A physical barrier is recommendedif there are at risk individuals in the house. To restrictaccess to a fireplace <strong>or</strong> stove, install an adjustablesafety gate to keep toddlers, young children and otherat risk individuals out of the room and away from hotsurfaces.7. Do not modify fireplace under any circumstances. Anyparts removed f<strong>or</strong> servicing must be replaced pri<strong>or</strong> tooperating fireplace.8. Turn fireplace off and let cool bef<strong>or</strong>e servicing, installing,<strong>or</strong> repairing. Only a qualified service person shouldinstall, service, <strong>or</strong> repair the fireplace. Have burnersystem inspected annually by a qualified serviceperson.9. You must keep control compartments, burners, andcirculating air passages clean. M<strong>or</strong>e frequent cleaningmay be needed due to excessive lint and dust. Turn offthe gas valve and pilot light bef<strong>or</strong>e cleaning fireplace.10. Have venting system inspected annually by a qualifiedservice person. If needed, have venting systemcleaned <strong>or</strong> repaired. See Cleaning and Maintenance,Page 48.11. Keep the area around your fireplace clear of combustiblematerials, gasoline, and other flammable vap<strong>or</strong> andliquids. Do not run fireplace where these are used <strong>or</strong>st<strong>or</strong>ed. Do not place items such as clothing <strong>or</strong> dec<strong>or</strong>ationson <strong>or</strong> around fireplace.Continued on page 4

!CDVSC7 & CDV7 Series <strong>Gas</strong> Fireplace12. Do not use this fireplace to cook food <strong>or</strong> burn paper <strong>or</strong>other objects.13. Never place anything on top of fireplace.14. Do not use any solid fuels (wood, coal, paper, cardboard,etc.) in this fireplace. Use only the gas typeindicated on rating plate.15. This appliance, when installed, must be electricallygrounded in acc<strong>or</strong>dance with local codes <strong>or</strong> in theabsence of local codes, with the National ElectricalCode, ANSI/NFPA 70, <strong>or</strong> the Canadian Electrical Code,CSA C22.1.16. Do not obstruct the flow of combustion and ventilationair in any way. Provide adequate clearances aroundair openings into the combustion chamber along withadequate accessibility clearance f<strong>or</strong> servicing andproper operation.17. When the appliance is installed directly on carpeting,tile <strong>or</strong> other combustible material other than woodflo<strong>or</strong>ing, you must set appliance on a metal <strong>or</strong> woodpanel <strong>or</strong> hearth pad extending the full width and depthof the appliance.18. Do not use fireplace if any part has been exposed to<strong>or</strong> has been under water. Immediately call a qualifiedservice person to arrange f<strong>or</strong> replacement of theunit.19. Do not operate fireplace if any log is broken.20. Do not use a blower insert, heat exchanger insert, <strong>or</strong>any other access<strong>or</strong>y not approved f<strong>or</strong> use with thisfireplace.21. Do not operate the fireplace with glass do<strong>or</strong> removed,cracked, <strong>or</strong> broken.Code ApprovalDirect Vent type appliances draw all combustion air fromoutside of the dwelling through the vent pipe.These appliances have been tested by CSA and foundto comply with the established standards in the USA andCanada as follows:LISTED VENTED GAS FIREPLACE HEATERTESTED TO (latest edition):CDVR: ANSI Z21.88 / CSA 2.33 STANDARDSLISTED VENTED GAS FIREPLACECDVT: ANSI Z21.50 CSA 2.22 STANDARDSA manufactured home (USA only) <strong>or</strong> mobile home OEMinstallation must conf<strong>or</strong>m with the Manufactured HomeConstruction and Safety Standard, Title 24 CFR, Part3280, <strong>or</strong> when such a standard is not applicable, theStandard f<strong>or</strong> Manufactured Home Installations, ANSI/NCSBCS A225.1, <strong>or</strong> Standard f<strong>or</strong> <strong>Gas</strong> Equipped RecreationalVehicles and Mobile Housing, CSA Z240.4.IMPORTANT SAFETY INFORMATIONIMPORTANT:PLEASE READ THE FOLLOWING CAREFULLYIt is n<strong>or</strong>mal f<strong>or</strong> fireplaces fabricated of steelto give off some expansion and/<strong>or</strong> contractionnoises during the start up <strong>or</strong> cool down cycle.Similar noises are found with your furnace heatexchanger <strong>or</strong> car engine.IMPORTANT:PLEASE READ THE FOLLOWING CAREFULLYIt is not unusual f<strong>or</strong> gas fireplace to give off someod<strong>or</strong> the first time it is burned. This is due to themanufacturing process.Please ensure that your room is wellventilated during burn off — open allwindows.It is recommended that you burn your fireplacef<strong>or</strong> at least ten (10) hours the first time you use it.Place the fan switch in the “OFF” position duringthis time.WARNINGNever connect unit to private (non-utility)gas wells. This gas is commonly knownas wellhead Nous gas. recommandons que nosappareils de chauffage au gazsoient installés et entretenus pardes professionnels qui ont étéaccrédités aux È.U. par le NationalFireplace Institute ® (NFI) comme!étantWARNINGdes spécialistes du NFI enmatièred’appareils HOT GLASS de chauffage WILLau gaz. CAUSE BURNS.DO NOT TOUCH GLASSUNTIL COOLED.NEVER ALLOW CHILDRENTO TOUCH GLASS.69D3011

product featuresCDVSC7 & CDV7 Series <strong>Gas</strong> Fireplaceproduct SPECIFICATIONS• This appliance has been certified f<strong>or</strong> use with eithernatural <strong>or</strong> propane gas. See appropriate data plates.• This appliance is not f<strong>or</strong> use with solid fuels.• The appliance is approved f<strong>or</strong> bedroom <strong>or</strong> bedsittingroom installations.• The appliance must be installed in acc<strong>or</strong>dance with localcodes if any. If none exist use the current installationcode. ANSI Z223.1/NFPA 54 in the USA, CSA B149 inCanada.• This appliance is mobile home approved.• The appliance must be properly connected to a ventingsystem.• The appliance is not approved f<strong>or</strong> closet installations.• This appliance is approved to be vented with Simpson-Duravent and MHSC Twist-Lock Direct Vent Components.Remote ControlSwitch ReceiverHi/Lo KnobOff/Pilot/On KnobIgnit<strong>or</strong>Figure 1 -CDV7 Series FireplaceOn/Off/RSSwitchBlowerControlFP2284The classification “noncombustible material” includes, butis not limited to stone, brick and m<strong>or</strong>tar. Noncombustiblesare safe to overlay the black-painted metal face (includingradiant plates) and do not pose a fire hazard. Do notallow any noncombustible finish material to extend past <strong>or</strong>interfere with fireplace opening.The classification “combustible material” includes, but is notlimited to plywood, drywall and particle board. Combustiblematerials may contact the sides, bottom <strong>or</strong> back of firebox.Do not overlay the black painted face with combustiblematerials.FP2284aCDV7 controls69D3011

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceHIGH ELEVATIONSInput ratings are shown in BTU per hour and are certifiedwithout deration f<strong>or</strong> elevations up to 4,500 feet (1,370m) above sea level.F<strong>or</strong> elevations above 4,500 feet (1,370 m) in USA,installations must be in acc<strong>or</strong>dance with the currentANSI Z223.1/NFPA 54 and/<strong>or</strong> local codes having jurisdiction.In Canada, please consult provincial and/<strong>or</strong> local auth<strong>or</strong>itieshaving jurisdiction f<strong>or</strong> installations at elevationsabove 4,500 feet (1,370 m).GAS SPECIFICATIONS & ORIFICE SIZECDVR SERIESMax.Input Min. Input OrificeModel Fuel BTU/h BTU/h SizeCDVR33NV7 Nat. 18,000 13,000 #45CDVR33NV117 Nat. 18,000 13,000 #45CDVR33NE7 Nat. 18,000 13,000 #45CDVR33NSC117 Nat. 18,000 13,000 #45CDVR36NV7 Nat. 20,000 15,000 #44CDVR36NE7 Nat. 20,000 15,000 #44CDVR36NSC7 Nat. 20,000 15,000 #44CDVR42NV7 Nat. 24,000 17,000 2.35 mmCDVR42NE7 Nat. 24,000 17,000 2.35 mmCDVR42NSC7 Nat. 24,000 17,000 2.35 mmCDVR47NV7 Nat. 24,000 17,000 2.35 mmCDVR47NE7 Nat. 24,000 17,000 2.35 mmCDVR47NSC7 Nat. 24,000 17,000 2.35 mmCDVR33PV7 LP 18,000 13,000 1.28 mmCDVR33PV117 LP 17,000 14,000 1.25 mmCDVR33PE7 LP 18,000 13,000 1.28 mmCDVR33PSC117 LP 17,000 14,000 1.25 mmCDVR36PV7 LP 20,000 15,000 1.35 mmCDVR36PE7 LP 20,000 15,000 1.35 mmCDVR36PSC7 LP 20,000 15,000 1.35 mmCDVR42PV7 LP 24,000 18,000 1.45 mmCDVR42PE7 LP 24,000 18,000 1.45 mmCDVR42PSC7 LP 24,000 18,000 1.45 mmCDVR47PV7 LP 24,000 18,000 1.45 mmCDVR47PE7 LP 24,000 18,000 1.45 mmCDVR47PSC7 LP 24,000 18,000 1.45 mmproduct features & <strong>Gas</strong> specificationsGAS pressuresNatural Propane (LP)Inlet Minimum 5.5” w.c. 11.0” w.c.Inlet Maximum 14.0” w.c. 14.0” w.c.Manifold Pressure 3.5” w.c. 10.0” w.c.GAS SPECIFICATIONS & ORIFICE SIZECDVT SERIESMax.Input Min. Input OrificeModel Fuel BTU/h BTU/h SizeCDVT33NV7 Nat. 18,000 13,000 #45CDVT33PV7 LP 18,000 13,000 1.28 mmCDVT33NE7 Nat. 18,000 13,000 #45CDVT33PE7 LP 18,000 13,000 1.28 mmCDVT33NSC7 Nat. 18,000 13,000 #45CDVT33PSC7 LP 18,000 13,000 1.28 mmCDVT36NV7 Nat. 20,000 15,000 #44CDVT36PV7 LP 20,000 15,000 1.35 mmCDVT36NE7 Nat. 20,000 15,000 #44CDVT36PE7 LP 20,000 15,000 1.35 mmCDVT36NSC7 Nat. 20,000 15,000 #44CDVT36PSC7 LP 20,000 15,000 1.35 mmCDVT42NV7 Nat. 24,000 17,000 2.35 mmCDVT42PV7 LP 24,000 18,000 1.45 mmCDVT42NE7 Nat. 24,000 17,000 2.35 mmCDVT42PE7 LP 24,000 18,000 1.45 mmCDVT42NSC7 Nat. 24,000 17,000 2.35 mmCDVT42PSC7 LP 24,000 18,000 1.45 mmCDVT47NV7 Nat. 24,000 17,000 2.35 mmCDVT47PV7 LP 24,000 18,000 1.45 mmCDVT47NE7 Nat. 24,000 17,000 2.35 mmCDVT47PE7 LP 24,000 18,000 1.45 mmCDVT47NSC7 Nat. 24,000 17,000 2.35 mmCDVT47PSC7 LP 24,000 18,000 1.45 mm69D3011

fireplace dimensions & FRAMINGCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceGMinimum RoughOpeningDepthM1/2” <strong>or</strong> 5/8”5/8”1/2”5/8”1/2”FOLNMP - Minimum Rough Opening WidthMinimum RoughOpeningHeight1”5/8”Q1/2”C LDECHB1/2”15/16”Figure 2 -CDVR Series Fireplace DimensionsIAJK5/8”NOTE: Models CDVR33SC7 & CDVR33V117have no standoffs on top of unit.CDVR33(V)(SC)117 CDVR33(V,E)7 CDVR36(V,E,SC)7 CDVR42(V,E,SC)7 CDVR47(V,E,SC)7A 33C\," (848 mm) 33" (838 mm) 37Z\zn" (941 mm) 41" (1041 mm) 47" (1194 mm)B see note 35B\," (905 mm) 38B\," (981 mm) 38B\," (981 mm) 38B\," (981 mm)693011CDVR7 DIMSC 31ZZ\zn" (805 mm) 31ZZ\zn" (805 mm) 34>\zn" (878 mm) 34>\zn" (878 mm) 34>\zn" (878 mm)D 27C\zn" (691 mm) 27C\zn" (691 mm) 29Z\zn" (738 mm) 33Z\zn" (840 mm) 39Z\zn" (992 mm)E 15C\zn" (386 mm) 15C\zn" (386 mm) 20C\," (518 mm) 20C\," (518 mm) 20C\," (518 mm)F 11C\v" (299 mm) 14C\zn" (360 mm) 15C\v" (400 mm) 15C\v" (400 mm) 15C\v" (400 mm)G 21Z\x" (546 mm) 21C\," (546 mm) 21M\," (556 mm) 25M\," (657 mm) 31M\," (810 mm)H 21ZB\zn" (557 mm) 21ZB\zn" (557 mm) 25Z\v" (641 mm) 25Z\v" (641 mm) 25Z\v" (641 mm)I 29M\," (759 mm) 29M\," (759 mm) 32" (813 mm) 36" (914 mm) 42" (1067 mm)J 2B\zn" (59 mm) 2B\zn" (59 mm) 2C\," (60 mm) 2C\," (60 mm) 2C\," (60 mm)K 5" (127 mm) 7C\zn" (183 mm) 5M\zn" (138 mm) 5M\zn" (138 mm) 5M\zn" (138 mm)Framing DimensionsL 51" (1295 mm) 48C\v" (1238 mm) 52M\zn" (1332 mm) 56M\zn" (1434 mm) 62M\zn" (1586 mm)M 36" (914 mm) 34Z\x" (876 mm) 37Z\zn" (941 mm) 40" (1016 mm) 44Z\," (1121 mm)N 25Z\x" (648 mm) 24C\," (619 mm) 26Z\v" (667 mm) 28Z\v" (718 mm) 31Z\v" (794 mm)O 11Z\v" (286 mm) 13ZZ\zn" (347 mm) 15Z\v" (387 mm) 15Z\v" (387 mm) 15Z\v" (387 mm)P 33B\," (854 mm) 33Z\v" (845 mm) 37Z\x" (953 mm) 41Z\v" (1048 mm) 47Z\v" (1200 mm)Q 32Z\v" (819 mm) 35M\," (911 mm) 39" (991 mm) 39" (991 mm) 39" (991 mm)69D3011

CDVSC7 & CDV7 Series <strong>Gas</strong> Fireplacefireplace dimensions & FRAMINGHGMinimum RoughOpeningDepthN1/2” <strong>or</strong> 5/8”I5/8”1/2”5/8”1/2”FPMONQ - Minimum Rough Opening WidthMinimum RoughOpeningHeight1”5/8”R1/2”DECB1/2”15/16”Figure 3 -CDVT Series Fireplace DimensionsAJCDVT33(V,E,SC)7 CDVT36 (V,E,SC)7 CDVT42 (V,E,SC)7 CDVT47 (V,E,SC)7A 33" (38 mm) 37Z\zn" (941 mm) 41" (1041 mm) 47" (1194 mm)B 35B\," (905 mm) 38B\," (981 mm) 38B\," (981 mm) 38B\," (981 mm)C 31ZZ\zn" (805 mm) 34>\zn" (878 mm) 34>\zn" (878 mm) 34>\zn" (878 mm)693011CDVT7 top dimsD 27C\zn" (691 mm) 29Z\zn" (738 mm) 33Z\zn" (840 mm) 39Z\zn" (992 mm)E 15C\zn" (386 mm) 20C\," (518 mm) 20C\," (518 mm) 20C\," (518 mm)F 14C\zn" (360 mm) 15C\v" (400 mm) 15C\v" (400 mm) 15C\v" (400 mm)G 21C\," (546 mm) 21M\," (556 mm) 25M\," (657 mm) 31M\," (810 mm)H 10ZZ\zn" (272 mm) 10ZB\zn" (278 mm) 12ZB\zn" (329 mm) 15ZB\zn" (405 mm)I 6Z\x" (165 mm) 6Z\x" (165 mm) 6Z\x" (165 mm) 6Z\x" (165 mm)J 29M\," (759 mm) 32" (813 mm) 36" (914 mm) 42" (1067 mm)K 2B\zn" (59 mm) 2C\," (60 mm) 2C\," (60 mm) 2C\," (60 mm)L 7C\zn" (183 mm) 5M\zn" (138 mm) 5M\zn" (138 mm) 5M\zn" (138 mm)Framing DimensionsM 48C\v" (1238 mm) 52M\zn" (1332 mm) 56M\zn" (1434 mm) 62M\zn" (1586 mm)N 34Z\x" (876 mm) 37Z\zn" (941 mm) 40" (1016 mm) 44Z\," (1121 mm)O 24C\," (619 mm) 26Z\v" (667 mm) 28Z\v" (718 mm) 31Z\v" (794 mm)P 13ZZ\zn" (347 mm) 15Z\v" (387 mm) 15Z\v" (387 mm) 15Z\v" (387 mm)Q 33Z\v" (845 mm) 37Z\x" (953 mm) 41Z\v" (1048 mm) 47Z\v" (1200 mm)R 35M\," (911 mm) 39" (991 mm) 39" (991 mm) 39" (991 mm)KL5/8”69D3011

pRE-INSTALLATION INFORMATIONBef<strong>or</strong>e You StartRead this homeowner manual th<strong>or</strong>oughly and follow allinstructions carefully. Inspect all contents f<strong>or</strong> shippingdamage and immediately inf<strong>or</strong>m your dealer if any damageis found. Do not install any unit with damaged, incomplete,<strong>or</strong> substitute parts. Check your packing list to verify thatall listed parts have been received. You should have thefollowing:• Fireplace (Firebox and Burner System)• <strong>Log</strong> Set• Volcanic Rock• Rock WoolItems Required F<strong>or</strong> InstallationTools:Building Supplies:• Phillips Screwdriver • Framing Materials• Hammer• Wall Finishing Materials• Saw and/<strong>or</strong> saber saw • Level• Electric Drill and Bits • Tee Joint• Pliers• Measuring Tape• Square• Pipe Wrench• Caulking Material (Noncombustible)• Fireplace Surround Material (Noncombustible)• Piping Complying with Local Codes• Pipe Sealant Approved f<strong>or</strong> use with Propane/LPG(Resistant to Sulfur Compounds)CDVSC7 & CDV7 Series <strong>Gas</strong> Fireplacefirebox framing FOR CDVRFirebox framing can be built bef<strong>or</strong>e <strong>or</strong> after the appliance isset in place. Construct firebox framing following Figure 2 f<strong>or</strong>your specific installation requirements. Refer to Figure 2 f<strong>or</strong>firebox dimensions. The framing headers may rest on thetop of the firebox standoffs. Do not bring headers belowtop of standoffs. NOTE: CDVR33SC7 & CDVR33117 donot have standoffs.The firebox may be installed directly on a combustible flo<strong>or</strong><strong>or</strong> raised on a platf<strong>or</strong>m of an appropriate height. Whenthe firebox is installed directly on carpeting, tile, <strong>or</strong> othercombustible material, other than wood flo<strong>or</strong>ing, the fireboxshall be installed on a metal <strong>or</strong> wood panel extending thefull width and depth of the enclosure.firebox framing FOR CDVTFirebox framing can be built bef<strong>or</strong>e <strong>or</strong> after the applianceis set in place. Construct firebox framing following Figure 3f<strong>or</strong> your specific installation requirements. Refer to Figure3 f<strong>or</strong> firebox dimensions. The framing headers may reston the top of the firebox standoffs. Do not bring headersbelow top of standoffs.The firebox may be installed directly on a combustible flo<strong>or</strong><strong>or</strong> raised on a platf<strong>or</strong>m of an appropriate height. Whenthe firebox is installed directly on carpeting, tile, <strong>or</strong> othercombustible material, other than wood flo<strong>or</strong>ing, the fireboxshall be installed on a metal <strong>or</strong> wood panel extending thefull width and depth of the enclosure.WARNINGDo not fill spaces around firebox withinsulation <strong>or</strong> other materials. This couldcause a fire.NOTECOLD CLIMATE INSULATIONIf you live in a cold climate, seal all cracks around your appliance, andwherever cold air could enter the room, with noncombustible material.It is especially imp<strong>or</strong>tant to insulate the outside chase cavity betweenthe studs and under the flo<strong>or</strong> on which the appliance rests, if the flo<strong>or</strong>is above ground level.69D3011

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplacepRE-INSTALLATION INFORMATIONFireplace LocationPlan f<strong>or</strong> the installation of your appliance. This includes determining where the unit is to be installed,the vent configuration to be used, framing and finishing details, and whether any optional access<strong>or</strong>ies(i.e. blower, wall switch, <strong>or</strong> remote control) are desired. Consult your local building code agency toensure compliance with local codes, including permits and inspections.The following fact<strong>or</strong>s should be taken into consideration:• Clearance to side-wall, ceiling, woodw<strong>or</strong>k, and windows. Minimum clearances to combustiblesmust be maintained.• This fireplace may be installed along a wall, across a c<strong>or</strong>ner, <strong>or</strong> use an exteri<strong>or</strong> chase. Refer toFigure 4 f<strong>or</strong> suggested locations.• Location should be out of high traffic areas and away from furniture and draperies due to heatfrom appliance.• Never obstruct the front opening of the fireplace.• Do not install in the vicinity where gasoline <strong>or</strong> other flammable liquids may be st<strong>or</strong>ed.• Vent pipe routing. See Venting section found in this manual f<strong>or</strong> allowable venting configurations.• These units can be installed in a bedroom. See National Fuel <strong>Gas</strong> Code ANSI Z233.1/NFPA 54— (current edition), the Unif<strong>or</strong>m Mechanical Code — (current edition), and Local Building Codesf<strong>or</strong> specific installation requirements.YYEDFABXCBFigure 4 -LU584-1Locating <strong>Gas</strong> Fireplace Locating unit2/4/99 djtABCDEFYFlat on WallCross C<strong>or</strong>nerIsland**Room Divider*Flat on Wall C<strong>or</strong>ner*Chase Installation4" Minimum** Island (C) and room divider (D) installation is possible as longas the h<strong>or</strong>izontal p<strong>or</strong>tion of vent system (X) does not exceed20'.* When you install your fireplace in (D) room divider <strong>or</strong> (E)flat on wall c<strong>or</strong>ner positions (Y), a minimum of 4" clearancemust be maintained from perpendicular wall and front offireplace.10 69D3011

CLEARANCESCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceClearances to combustiblesWARNINGFollow these instructions carefully toensure safe installation. Failure to followinstructions exactly can create a firehazard.The appliance cannot be installed on acarpet, tile <strong>or</strong> other combustible materialother than wood flo<strong>or</strong>ing. If installed oncarpet <strong>or</strong> vinyl flo<strong>or</strong>ing, the applianceshall be installed on a metal, wood <strong>or</strong>noncombustible material panel extendingfull width and depth of the appliance.Finish Wall12” (305 mm)8” (203 mm)A6” (152 mm)B 2”(64 mm)CDStudHeaderStandoffCeiling72"MinimumSideWallTop of HeatExhaust VentCDV33/36/42/47Side ViewFP2285bNOTE: CDVR33SC7 & CDVR33117have no standoffs.Ref. CDV33 CDV36 CDV42/47AB14" (356 mm) FP2285b 12" (305 mm)11" (279 mm) mantel 11" clearances (279 mm)12" (305 mm)9Z\x" (241 mm)C 10" (254 mm) 10" (254 mm) 8Z\x" (216 mm)D 8" (203 mm) 8" (203 mm) 6" (152 mm)Stud6”MinimumFigure 5 -Ceiling and Side Wall Clearancesmantel clearancesfP2032wall clearancesFP2032NOTE: The combustible area above the facing mustnot protrude m<strong>or</strong>e than 3/4" from the facing. If it does,it is considered a mantel and must meet the mantelrequirements listed in this manual.NOTE: The MHSC Barrington Cabinet Mantel Model seriesBWC300, BWC400 and BWC500 are specially designedto comply with all mantel temperature requirements. Anycustom-built mantel must comply with all clearance requirementsshown in this instruction manual.WARNINGFP2286Side of FireplaceOpeningFront ViewFigure 6 -Mantel Clearances1" 1”3”2”4”3" 45°5"FP2286Mantel leg clearNever obstruct <strong>or</strong> modify the air inlet <strong>or</strong>outlet grilles (louvers). This may createa fire hazard.6"WallCombustibleMaterial Area69D3011 11

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceSECURE FIREPLACE to flo<strong>or</strong> <strong>or</strong> framingThe fireplace must be secured to theflo<strong>or</strong> and/<strong>or</strong> to framing studs as shownin Figure 7. Use two (2) wood screws<strong>or</strong> masonry/ concrete screws to securefireplace to the flo<strong>or</strong>. Use four (4) screwsto attach fireplace to framing. The sidenailing flanges are 1/2" <strong>or</strong> 5/8" to accommodatedifferent wall thickness.FramingNailingFlangeDrywall Supp<strong>or</strong>t Tabs (DoNot Use f<strong>or</strong> Framing <strong>or</strong>Header)ScrewsFramingNailingFlangeScrewScrewNailingFlangesFigure 7 -Securing Fireplace to Flo<strong>or</strong> andFraming Studs (CDVT36 shown)ScrewScrewFP2287Finishing MaterialNOTE: Any wiring (i.e. remote control, wall switch, and optional fan) must be done pri<strong>or</strong> to finalfinishing to avoid costly reconstruction.FP2287secure fireplaceOnly noncombustible materials (i.e. brick, tile, slate, steel, <strong>or</strong> other materials with a UL fire ratingof Zero) may be used to cover the black surface of the appliance. A 300°F minimum adhesivemay be used to attach facing materials to the black surface. If joints between the finished walland the fireplace surround are sealed, a 300°F minimum sealant material (General ElectricRTV103 <strong>or</strong> equivalent) must be used.12 69D3011

Venting INSTALLATION INFORMATIONCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceWARNINGRead all instructions completely and th<strong>or</strong>oughly bef<strong>or</strong>e attempting installation. Failureto do so could result in serious injury, property damage <strong>or</strong> loss of life. Operation ofimproperly installed and maintained venting system could result in serious injury,property damage <strong>or</strong> loss of life.installation precautionsConsult local building codes bef<strong>or</strong>e beginning theinstallation. The installer must make sure to select theproper vent system f<strong>or</strong> installation. Bef<strong>or</strong>e installing ventkit, the installer must read this fireplace manual and ventkit instructions.Only a qualified installer/service person should install ventingsystem. The installer must follow these safety rules:• Wear gloves and safety glasses f<strong>or</strong> protection.• Use extreme caution when using ladders <strong>or</strong> when onrooftops.• Be aware of electrical wiring locations in walls andceilings.The following actions will void the warranty on your ventingsystem:• Installation of any damaged venting component.• Unauth<strong>or</strong>ized modification of the venting system.• Installation of any component part not manufactured<strong>or</strong> approved by MHSC.• Installation other than permitted by these instructions.WARNINGWARNINGThis fireplace must be vented to theoutside. The venting system must NEVERbe attached to a chimney serving a separatesolid fuel burning appliance. Each gasappliance must use a separate vent system.Do not use common vent systems.Always maintain minimum clearances aroundvent systems. The minimum clearances tocombustibles f<strong>or</strong> h<strong>or</strong>izontal vent pipe are 3"at the top* and 1" at the sides and bottomof the vent system until the pipe penetratesthe nearest vertical wall (1" required). A 1"minimum clearance all around the pipe mustbe maintained at outside wall and on verticalruns. Do not pack the open air spaces withinsulation <strong>or</strong> other materials. This couldcause high temperatures and may presenta fire hazard.* Unless the vertical run is 7Z\x feet <strong>or</strong> higher(top vent units only), the clearances f<strong>or</strong> theh<strong>or</strong>izontal run is 1" at the top.General VentingYour fireplace is approved to be vented either through theside wall, <strong>or</strong> vertical through the roof.• Only MHSC venting components specifically approvedand labelled f<strong>or</strong> this fireplace may be used.• Flexible UL1777 listed venting may be used in any ventingapplication where rigid direct vent components canbe used. All restrictions, clearances and allowances thatpertain to the rigid piping apply to the flexible venting.Flex kits may not be modified. Flex kits may be added tothe end of a vent run made of rigid vent sections usingpipe manufacturer's approved flex to pipe adapters. Thismay occur only if doing so does not violate any of theventing length, height, routing, h<strong>or</strong>izontal to vertical rait<strong>or</strong>equirements <strong>or</strong> clearance considerations detailed in thismanual.• Venting terminals shall not be recessed into a wall <strong>or</strong> siding.• Select the amount of vertical rise desired. All h<strong>or</strong>izontalrun of venting must have 1/4" rise f<strong>or</strong> every 12" of runtowards the termination below 7 1 /2 feet of vertical rise.With 7 1 /2 feet <strong>or</strong> m<strong>or</strong>e vertical rise off top of fireplace,the h<strong>or</strong>izontal run may run level. NEVER run vent pipingdownward.• H<strong>or</strong>izontal venting which inc<strong>or</strong>p<strong>or</strong>ates the twist lock pipemust be installed on a level plane without an inclining <strong>or</strong>declining slope.• H<strong>or</strong>izontal venting which inc<strong>or</strong>p<strong>or</strong>ates the use of flexventing shall have an inclining slope from the unit of 1”(25 mm) per 24” (610 mm).There must not be any obstruction such as bushes, gardensheds, fences, decks <strong>or</strong> utility buildings within 24”(610 mm) from the front of the termination hood.Do not locate termination hood where excessive snow <strong>or</strong>ice build up may occur. Be sure to check vent terminationarea after snow falls, and clear to prevent accidentalblockage of venting system. When using snow blowers,make sure snow is not directed towards vent terminationarea.Location of Vent TerminationIt is imperative the vent termination be located observingthe minimum clearances as shown on following page.NOTICEFailure to follow these instructions willvoid the warranty.69D3011 13

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceVenting INSTALLATION INFORMATIONGeneral Venting Inf<strong>or</strong>mation - Termination LocationFigure 8 -Termination LocationsLDVEBCFM145aFCV FixedClosedVBOperableBVABINSIDECORNER DETAILVGBFixedOperableClosedVAJV VENT TERMINATION X AIR SUPPLY INLET AREA WHERE TERMINAL IS NOT PERMITTEDCanadian Installations 1 uS Installations 2A = Clearance above grade, veranda, p<strong>or</strong>ch,CFM145a12” (30 cm) DV Termin Location12” (30 cm)5/01/01 Rev. 12/05/01deck, <strong>or</strong> balconystaB = Clearance to window <strong>or</strong> do<strong>or</strong> that may be 6” (15 cm) f<strong>or</strong> appliances 6” (15 cm) f<strong>or</strong> appliancesopened < 10,000BTU/h (3kW), 12” (30 cm) < 10,000 BTU/h (3kW), 9”f<strong>or</strong> appliances > 10,000 Btuh (3kW) and (23 cm) f<strong>or</strong> appliances > 10,000< 100,000 BTU/h (30kW), 36” (91 cm) Btuh (3kW) and < 50,000 BTU/hf<strong>or</strong> appliances > 100,000 BTU/h (30kW) (15kW), 12” (30 cm) f<strong>or</strong>appliances > 50,000 BTU/h(15kW)C = Clearance to permanently closed window 12” (305 mm) recommended to 12” (305 mm) recommended toprevent window condensationprevent window condensationD = Vertical clearance to ventilated soffit locatedabove the terminal within a h<strong>or</strong>izontal 18” (458 mm) 18” (458 mm)distance of 2’ (610mm) from the centerline of the terminalE = Clearance to unventilated soffit 12” (305 mm) 12” (305 mm)F = Clearance to outside c<strong>or</strong>ner see next page see next pageG = Clearance to inside c<strong>or</strong>ner (see next page) see next page see next pageH = Clearance to each inside of center line 3’ (91 cm) within a height of 15’ (5 m) 3’ (91 cm) within a height of 15’extended above meter/regulat<strong>or</strong> assembly above the meter/regulat<strong>or</strong> assembly (5 m) above the meter/regulat<strong>or</strong>assyI = Clearance to service regulat<strong>or</strong> vent outlet 3’ (91 cm) 3’ (91 cm)J = Clearance to nonmechanical air supply inlet 6” (15 cm) f<strong>or</strong> appliances < 10,000 6” (15 cm) f<strong>or</strong> appliancesto building <strong>or</strong> the combustion air inlet to any BTU/h (3kW), 12” (30 cm) f<strong>or</strong> < 10,000 BTU/h (3kW), 9”other appliances appliances > 10,000 BTU/h (3kW) and (23 cm) f<strong>or</strong> appliances > 10,000< 100,000 Btuh (30kW), 36” (91 cm) BTU/h (3kW) and < 50,000 BTU/hf<strong>or</strong> appliances > 100,000 BTU/h (30kW) (15kW), 12” (30 cm) f<strong>or</strong>appliances > 50,000 BTU/h(15kW)K = Clearance to a mechanical air supply inlet 6’ (1.83 m) 3’ (91 cm) above if within 10'(3 m) h<strong>or</strong>izontallyL = Clearance above paved sidewalk <strong>or</strong> paved 7’ (2.13 m)† 7’ (2.13 m)†driveway located on public propertyM = Clearance under veranda, p<strong>or</strong>ch, deck <strong>or</strong> 12” (30 cm) 12” (30cm)balconyVBXHIMVKX1 In acc<strong>or</strong>dance with the current CSA-B149 Installation Codes2 In acc<strong>or</strong>dance with the current ANSI Z223.1/NFPA 54 National Fuel<strong>Gas</strong> Codes† A vent shall not terminate directly above a sidewalk <strong>or</strong> paveddriveway which is located between two single familydwellings and serves both dwellings only permitted if veranda, p<strong>or</strong>ch, deck <strong>or</strong> balcony is fully open on aminimum 2 sides beneath the flo<strong>or</strong>:NOTE: 1. Local codes <strong>or</strong> regulations may require differentclearances.2. The special venting system used on Direct Vent Fireplacesare certified as part of the appliance, with clearancestested and approved by the listing agency.3. MHSC assumes no responsibility f<strong>or</strong> the improperperf<strong>or</strong>mance of the appliance when the venting systemdoes not meet these requirements.14 69D3011

Venting INSTALLATION INFORMATIONCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceTermination ClearancesTermination clearances f<strong>or</strong> buildings with combustible and noncombustible exteri<strong>or</strong>s.Inside C<strong>or</strong>nerOutside C<strong>or</strong>nerAlcove Applications*GVG =Combustible6" (152 mm)Noncombustible2" (51 mm)VFF =Combustible6" (152 mm)Noncombustible2" (51 mm)CODVECBalcony -with no side wallMVM =Combustible &Noncombustible12" (305 mm)Balcony -with perpendicular side wallMCombustible &NoncombustibleM = 24" (610 mm)P = 20” (508 mm)VPE = Min. 6” (152 mm) f<strong>or</strong>non-vinyl sidewallsMin. 12” (305 mm) f<strong>or</strong>vinyl sidewallsO = 8’ (2.4 m) Min.No.of Caps DMin. CMax.1 3’ (914 mm) 2 x DActual2 6’ (1.8 m) 1 x DActual3 9’ (2.7 m) 2/3 x DActual4 12’ (3.7 m) 1/2 x DActualDMin. = # of Termination caps x 3CMax. = (2 / # termination caps) x DActual*NOTE: Termination in an alcove space (spaces open only on one side and with an overhang) is permitted with the dimensions specified f<strong>or</strong> vinyl <strong>or</strong>non-vinyl siding and soffits. 1. There must be a 3’ (914 mm) minimum between termination caps. 2. All mechanical air intakes within 10’ (1 m) of atermination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All gravity air intakes within 3’ (914 mm) of a termination cap mustbe a minimum of 1’ (305 mm) below the termination cap. Figure 9 -Termination ClearancesGeneral Inf<strong>or</strong>mation Assembling Vent PipesUSA InstallationsThe venting system must conf<strong>or</strong>m to local codes and/<strong>or</strong>the current National Fuel Code ANSI Z223.1/NFPA 54.Only venting components manufactured <strong>or</strong> approved byMHSC may be used in Direct Vent systems.Canadian InstallationsThe venting system must be installed in acc<strong>or</strong>dance withthe current CSA-B149.1 installation code.584-15* Be sure the vent is actually crushed bef<strong>or</strong>e proceeding.Apply a tug to be sure the vent will not slip off the collars.Repeat process with 7” flex vent pipe. The same proceduremust be perf<strong>or</strong>med on the vent side.Flex Vent PipesSecure flex vent pipe in place with a hose clamp (provided).*Be sure the flex pipe overlaps at least 1” (25 mm) ontothe collars of the fireplace and termination. If the terminationhas an internal bead, be sure to overlap and secure1” (25 mm) past the bead.FP2290Figure 10 -Suecure Flex Vent Pipe with Hose Clamps.Hose Clamp69D3011 15

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceTwist Lock PipesWhen using twist lock pipe it is not necessary to use sealanton the joints.To join twist lock pipes together, simply align the beads ofthe male end with the grooves of the female end, twistingthe pipe until the flange on the female end contacts externalflange on the male end. It is recommended that yousecure the joints with three (3) sheet metal screws, however,this is not mandat<strong>or</strong>y with twist lock pipe. Figure 11NOTE: Sealant is not required to assemble fireplaceventing. Do not use silicone sealant at the inner flueexhaust connections.To make it easier to assembly the joints, we suggest puttinga lubricant (Vaseline <strong>or</strong> similar) on the male end of thetwist lock pipe pri<strong>or</strong> to assembly.Venting INSTALLATION INFORMATIONREAR VENT INSTALLATION ONLY:Install the 4” (102 mm) vent pipe to the appliance innercollar and secure with three (3) stainless steel sheet metalscrews. Install the 7” (178 mm) vent pipe to the applianceouter collar. Secure pipe to the rear cover plate using thetabs and three (3) sheet metal screws. If a 45° <strong>or</strong> 90°elbow is being used, attach the elbow to the appliance inthe same manner then attach the venting to the elbow.TabsSheet MetalScrewsMale EndFemale EndTWL100Screw HolesFigure 11 -Twist-lock Pipe JointsTWL100Twist Lock Pipe3/12/99 djtFigure 12 -Rear Vent InstallationKT1129KT1129cdv add rear vent16 69D3011

Venting INSTALLATION INFORMATIONHow to Use the Vent GraphThe Vent Graph should be read in conjunction with thefollowing vent installation instructions to determine the relationshipbetween the vertical and h<strong>or</strong>izontal dimensionsof the vent system.1. Determine the height of the center of the h<strong>or</strong>izontalvent pipe exiting through the outer wall. Using this dimensionon the Sidewall Vent Graph, Figure 13, locatethe point intersecting with the slanted graph line.2. From the point of this intersection, draw a vertical lineto the bottom of the graph.3. Select the indicated dimension, and position the fireplacein acc<strong>or</strong>dance with same.EXAMPLE A:If the vertical dimension from the flo<strong>or</strong> of the unit is 11’ (3.4m) the h<strong>or</strong>izontal run to the face of the outer wall must notexceed 14’ (4.3 m).EXAMPLE B:If the vertical dimension from the flo<strong>or</strong> of the unit is 7’ (2.1m), the h<strong>or</strong>izontal run to the face of the outer wall must notexceed 8’ (2.4 m).Refer to Page 24 f<strong>or</strong> sn<strong>or</strong>kel requirements.Vertical Dimension from the Flo<strong>or</strong> of Unit to the Center ofthe H<strong>or</strong>izontal Vent PipeCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceX403836343230282624222018161412108642eg: A2 4 6 8 10 12 14 16 18 20H<strong>or</strong>izontal Dimension From the Outside of Termination tothe Back of the FireplaceX = 22" minimum f<strong>or</strong> 33" ModelX = 25Z\v" minimum f<strong>or</strong> 36", 42" and 47" Models(Flo<strong>or</strong> to center of h<strong>or</strong>izontal pipe)Figure 13 -Side Wall Venting GraphFP2291vent graph69D3011 17

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceVENT PIPE CLEARANCESA Minimum of 3" Clearanceto the Top Is Required AlongH<strong>or</strong>izontal Length until FluePipe Penetrates OutsideWall.3"1"1" 1"A Minimum 1" Clearanceto Combustibles PermittedAll Around Flue at OutsideWallA Minimum of 3" Clearanceto the Top Is RequiredAlong H<strong>or</strong>izontal Lengthuntil Flue Pipe PenetratesOutside Wall.Venting installation3"1"1" 1"A Minimum 1"Clearance toCombustiblesPermitted AllAround Flue atOutside WallCDVR SeriesFP2289CDVT SeriesFP2288Figure 14 -Combustible Clearances f<strong>or</strong> Vent PipeWARNINGFP2289Rear Vent: RV rear H<strong>or</strong>izontal vent sections of this ventsystem require a minimum of 3" clearancesto combustibles at the top of the flue and1" clearance at the sides and bottom untilthe flue penetrates the outside wall. Aminimum 1" clearance all around the flueis acceptable at this point of penetration.Vertical sections of this vent system requirea minimum of 1" clearance to combustibleson all sides of the pipe.WARNINGFP2288TV rear ventTop Vent: H<strong>or</strong>izontal sections of this ventsystem require a minimum of 3" clearancesto combustibles at the top of the flue and1" clearance at the sides and bottom untilthe flue penetrates the outside wall. Aminimum 1" clearance all around the flueis acceptable at this point of penetration. Ifvertical rise is 7 1 /2 feet <strong>or</strong> higher when topventing, the clearance to combustibles is1" on all sides of the h<strong>or</strong>izontal run.Vertical sections of this vent system requirea minimum of 1" clearance to combustibleson all sides of the pipe.18 69D3011

Venting installationCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceRear Wall Vent ApplicationWhen installed as a rear vent unit this appliance may bevented directly to a termination located on the rear wallbehind the appliance.• Only MHSC venting components are approved to beused in these applications (Refer to ‘Venting Components’listed f<strong>or</strong> different installation requirements).• The maximum h<strong>or</strong>izontal distance between the rear ofthe appliance (<strong>or</strong> end of the transition elbow in a c<strong>or</strong>nerapplication) and the outside face of the rear wall is20” (508 mm). Figure 14• Only one 45° elbow is allowed in these installations.• Minimum clearances between vent pipe and combustiblematerials are as follows:Top - 3” (76 mm)- except at outside wall 1" (25 mm)Sides - 1” (25 mm)Bottom - 1” (25 mm)9B\,”(244 mm)Min.Vent Opening f<strong>or</strong> Combustible Walls9B\,”(244 mm) Min.Fireplace HearthFraming DetailOpening f<strong>or</strong> Noncombustible Wall7Z\x”(190 mm)Figure 16 -Fireplace HearthLocate vent opening on wallFP2293Rear Vent Top View20”(508 mm)Max.Figure 15 -Rear Vent Application, No Elbows20”(508 mm)Max.FP1188REAR WALL FP1188 VENT INSTALLATION - TWISTLOCK PIPE rear wall installStep 1Locate and cut the vent opening in the wall.F<strong>or</strong> combustible walls first frame in opening. Figure 16NOTE: When using flex vent, the opening will have to bemeasured acc<strong>or</strong>ding to the 1” (25 mm) rise in 24” (610mm) vertical run.Combustible Walls: Cut a 9B\,”H x 9B\,” W (244 x 244mm) hole through the exteri<strong>or</strong> wall and frame as shown.Figure 16Noncombustible Walls: Hole opening should be 7Z\x”(191 mm) diameter.Step 2Secure firestop to the VO584-100 inside frame, center in the 9B\," x9B\," vent opening.Vent OpeningStep 3 2/99 djtMeasure the h<strong>or</strong>izontal length requirement f<strong>or</strong> the ventingincluding a 2” (51 mm) overlap, i.e. from the elbow to theoutside wall face plus 2” (51 mm). Figure 15Step 4Install the 4” (102 mm) vent to the appliance collar andsecure with 3 sheet metal screws. Install the 7” (178 mm)vent pipe to the appliance collar and secure with 3 sheetmetal screws. It is not necessary to seal this connection.If a 45° elbow is being used attach the elbow to the appliancein the same manner then attach the venting to theelbow.It is critical that there is no downward slopeaway from the appliance when connectingthe vent <strong>or</strong> elbow.Step 5Guide the venting through the vent hole as you place theappliance in its installed position. Guide the 4” (102 mm)and 7” (178 mm) collar of the vent termination into theouter ends of the venting. Do not f<strong>or</strong>ce the termination. Ifthe vent pipes do not align with the termination, removeand realign the venting at the appliance flue collars. Figure17. Attach the termination to the wall as outlined in theinstruction sheet supplied with the termination.69D3011 19

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceVenting installationFinish WallVentTerminationRiseFP1472Figure 17 -Side View of Final Unit LocationFP2294FP2294Side View Vent Termination1/25/00 djtRear Wall Vent Installations -Flex Vent PipeFollow Steps 1 and 2 on Page 19.Step 3Install the 4” (102 mm) flex vent pipe to the appliance collarsdescribed in “General Inf<strong>or</strong>mation Assembling VentPipes”, Page 12. If the installation requires a 45° angle,grasp the vent pipe close to the appliance collar and bendto 45°. DO NOT exceed 45°. Figure 18Install the 7” vent pipe in the same manner as Step 2.NOTE: There must be a 1/2” (13 mm) rise in a 12” (305mm) length of flex vent.Step 4Assemble the flex vent to the collars on the termination asyou did on the appliance.TerminationFlex Section<strong>Appliance</strong> CollarsFigure 19 -There must be a 1/2" rise per foot lengthTop vent Sidewall ApplicationNOTE: F<strong>or</strong> all top vent installations where a 90° elbowis the first pipe piece towards a sidewall termination (upFP1472and out), an open-center ringed flue restrict<strong>or</strong> must berise in lengthinstalled onto the top edge 4/04 of the djt firebox flue adapter. Tocreate this open-center restrict<strong>or</strong>,twist and break offthe center rib of the suppliedflue restrict<strong>or</strong>. The installedpart should appear similarto that show n in Figure 20.Since it is very imp<strong>or</strong>tantthat theFP2303Figure 20 -venting system Top Vent Vertical Sidewallmaintain its balance Restrict<strong>or</strong>between the combustionair intake and the flue CDV7 gas rear exhaust, restrict<strong>or</strong> certainFP2303limitations as to vent configurations 3/09 apply and mustbe strictly adhered to.The Vent Graph, showing the relationship between verticaland h<strong>or</strong>izontal side wall venting, will help to determinethe various dimensions allowable.Minimum clearance between vent pipes and combustiblematerials is 3" (76 mm) on top, and 1" (25 mm) onthe bottom and sides unless otherwise noted.When vent termination exits through foundations lessthan 20” (508 mm) below siding outcrop, the vent pipemust flush up with the siding.It is best to locate the fireplace in such a way that minimizesthe number of offsets and h<strong>or</strong>izontal vent length.The h<strong>or</strong>izontal vent run refers to the total length of ventpipe from the flue collar of the fireplace (<strong>or</strong> the top of theTransition Elbow) to the face of the outer wall.H<strong>or</strong>izontal plane means no vertical rise exists on this p<strong>or</strong>tionof the vent assembly.When installing the appliance as a rear vent unit, theFP1473Figure 18 -90° <strong>or</strong> 45° Transition Elbow attached directly to theGrasp the vent pipe close to the collar andrear of the unit is NOT INCLUDED in the following criteriabend to 45° angle. do not exceed 45°.and calculations, and unless specifically men-tioned should be ign<strong>or</strong>ed when calculating venting20layouts.69D3011FP1473

Venting installationCDVSC7 & CDV7 Series <strong>Gas</strong> Fireplace3 x 90°Elbows3 x 90°ElbowsABFigure 21 -Maximum three (3) 90° elbows per installation36"(914mm)Max.FP117636"(914mm)Max.7'6"(2.3m)A + B = 17' (Max.)(5.2m)FP1178 Figure 23 -H<strong>or</strong>izontal Run ReductionB7’(2.1 m)FP1177Figure 22 -Maximum h<strong>or</strong>izontal run with no rise• The maximum number of 90° elbows per side wall installationis three (3). Figure 21• If a 90° elbow is fitted Max directly 20" on top of the fireplaceflange the maximum h<strong>or</strong>izontal vent run bef<strong>or</strong>e the termination<strong>or</strong> a vertical rise is 36” (914 mm). Figure 22• If a 90° elbow is used in the h<strong>or</strong>izontal vent run (levelheight maintained) the h<strong>or</strong>izontal vent length is reducedby 36” (914 mm). Figures 22 & 23. This doesnot apply if the 90° elbows are used to increase <strong>or</strong>redirect a vertical rise. Figure 21Example: Acc<strong>or</strong>ding to the vent graph (Page 15) themaximum h<strong>or</strong>izontal vent length inMaxa system20"with a 7Z\x’(2.3 m) rise is 20’ (6 m) and if a 90° elbow is required inthe h<strong>or</strong>izontal vent it must be reduced to 17’ (5.2 m).In Figures 24 & 25, dimension A plus B must not be greaterthan 17’ (5.2m)• The maximum number of 45° elbows permitted per installationis six (6). These elbows can be installed ineither the vertical <strong>or</strong> h<strong>or</strong>izontal run.• F<strong>or</strong> each 45° elbow installed in the h<strong>or</strong>izontal run, thelength of the h<strong>or</strong>izontal run MUST be reduced by 18”(457 mm). This does not apply if the 45° elbows areinstalled on the vertical part of the vent system.• The maximum number of elbow degrees in a system is270°. Figure 25Example: Elbow 1 = 90°Elbow 2 = 45°Elbow 3 = 45°Elbow 4 = 90°Total angular variation = 270°7’6"(2.3 m)V584-201A 10’(3 m)1 + 2 + 3 + 4 = 270°1234FP1180Figure 24 -Maximum Vent Run with ElbowsV584-201H<strong>or</strong>izontal Run2/99 djtFigure 25 -Maximum Elbow Usage123469D3011 21

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceVertical Sidewall Installation -Twist Lock PipeStep 1Locate vent opening on the wall. It may be necessary tofirst position the fireplace and measure to obtain hole location.Depending on whether the wall is combustible <strong>or</strong>noncombustible, cut opening to size. Figure 26 (F<strong>or</strong> combustiblewalls first frame in opening.)NOTE: When using flex vent, the opening will have to bemeasured acc<strong>or</strong>ding to the 1/2” (13 mm) rise in 12” (305mm) vent run.Combustible Walls: Cut a 9B\,”H x 9%\,”W (244 x 244 mm)hole through the exteri<strong>or</strong> wall and frame as shown. Figure26Noncombustible Walls: Hole opening must be 7Z\x” (191mm) in diameter.9B\,”(244 mm)Vent Opening f<strong>or</strong> Combustible Walls9B\,”(244 mm)XFigure 27 -Vertical Height RequirementsVenting installationXFP1181Step 4Using appropriate length of pipe section(s) attach to fireplacewith three (3) screws. Follow with the installation ofthe inner and outer elbow, again secure joints with three(3) sheet metal screws.Step 5Measure the h<strong>or</strong>izontal length requirement including a 2”(51 mm) overlap, i.e. from the elbow to the outside wallface plus 2” (51 mm) (<strong>or</strong> the distance required if installinga second 90° elbow). Figure 28Always install h<strong>or</strong>izontal venting on a levelplane.Fireplace HearthFraming DetailOpening f<strong>or</strong> Noncombustible WallX7Z\x”(190 mm)Figure 26 -Fireplace HearthLocate Vent Opening on WallFP2293XStep 2Secure firestop to the VO584-100 inside frame, center in the 9B\," x9B\," vent opening. Vent Opening2/99 djtStep 3Place fireplace into position. Measure the vertical height(X) required from the base of the flue collars to the centerof the wall opening. Figure 27Figure 28 -H<strong>or</strong>izontal Length RequirementFP118222 69D3011

Venting installationCDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceStep 6Use appropriate length of pipe sections - telescopic <strong>or</strong>fixed - and install. The sections which go through the wallare packaged with the starter kit, and can be cut to suit ifnecessary.Step 7Guide the vent terminations 4” and 7” collard into theirrespective vent pipes. Double check that the vent pipesoverlap the collars by 2” (51 mm). Secure the terminationto the wall with screws provided and caulk aroundthe wall plate to weatherproof. As an alternative to screwingthe termination directly to the wall, you may also useexpanding plugs <strong>or</strong> an approved exteri<strong>or</strong> construction adhesive.You may also attach the termination with screwsthrough the inner body into the 4” vent pipe, however f<strong>or</strong>this method, you must extend the 4” pipe approximately6” (152 mm) beyond the outer face of the wall.Supp<strong>or</strong>t h<strong>or</strong>izontal pipes every 36” (914mm) with metal pipe straps.4” Flex Vent PipeSpacer SpringFP1474Figure 29 -Install Spacer Springs12"(305mm)6"(152mm)5"(127mm)6C\v"(172mm)Vertical Sidewall installation -flex vent pipeNOTE: The 40” (1016 mm) flex vent is used f<strong>or</strong> 90° off thetop of the unit then out the back wall.Follow Step 1 and 2 on Page 22.Step 3Install the four (4) spacer springs on the 4” flex vent pipe.When installing the spacer springs around the 4” pipe,stretch the spring to approximately 15” (381 mm), wrapthe spring around the pipe and interlock the ends of thespacer spring approximately 2” (51 mm). Measure 6C\v”(172 mm) from the end of the pipe. Place the next spring5” (127 mm) from the previously installed spring. Placethe next spring 6” (152 mm) from the last spring. Finallyplace the last spring 12” (305 mm) from the last springinstalled. Figure 29Step 4Install the 4” (102 mm) flex vent pipe to the appliance collaras described on Page 14. Secure the end with the firstspring 6C\v” (172 mm) from the flex pipe end to the unit.Step 5Slide the 7” (178 mm) flex vent pipe over the 4” flex ventpipe and secure the 7” collar as described on Page 14.Step 6FP1474Bend the flex pipe h<strong>or</strong>izontal spacer so the springs bottom of the h<strong>or</strong>izontalpipe measure 6Z\x” (165 4/04 mm) djt from the top of the unitimmediately after the 90° f<strong>or</strong>mation. Figure 30. Be sure tofollow the 1/2” (13 mm) rise in a 12” (305 mm) h<strong>or</strong>izontalrun rule.Step 7Install the 4” flex then 7” flex to the termination.FP14756Z\x" (165mm)Figure 30 -Bend flex vent at 90° so h<strong>or</strong>izontal p<strong>or</strong>tion is 6Z\x” (165mm) off top of unitFP1475flex 90 bend4/04 djt69D3011 23

CDVSC7 & CDV7 Series <strong>Gas</strong> FireplaceBELOW GRADE INSTALLATIONWhen it is not possible to meet the required vent terminalclearances of 12” (305 mm) above grade level, a sn<strong>or</strong>kelkit is recommended. It allows installation depth downto 7” (178 mm) below grade level. The 7” (178 mm) ismeasured from the center of the h<strong>or</strong>izontal vent pipe as itpenetrates through the wall.Ensure the sidewall venting clearances are observed.If venting system is installed below ground, we recommenda window well with adequate and properdrainage to be installed around the termination area.If installing a sn<strong>or</strong>kel, a minimum 24” (610 mm) verticalrise is necessary. The maximum h<strong>or</strong>izontal run with the24” vertical pipe is 36” (914 mm). This measurement istaken from the collar of the fireplace (<strong>or</strong> transition elbow)to the face of the exteri<strong>or</strong> wall. See the Sidewall VentingGraph f<strong>or</strong> extended h<strong>or</strong>izontal run if the vertical exceeds24” (610 mm).1. Establish vent hole through the wall. Page 22, Figure262. Remove soil to a depth of approximately 16” (406 mm)below base of sn<strong>or</strong>kel. Install drain pipe. Install windowwell (not supplied). Refill hole with 12” (305 mm) ofcoarse gravel leaving a clearance of approximately 4”(102 mm) below sn<strong>or</strong>kel. Figure 313. Install vent system.4. Ensure a watertight seal is made around the vent pipecoming through the wall.5. Apply high temperature sealant caulking (supplied)around the 4” and 7” sn<strong>or</strong>kel collars.6. Slide the sn<strong>or</strong>kel into the vent pipes and secure to thewall.7. Level the soil so as to maintain a 4” (102 mm) clearancebelow sn<strong>or</strong>kel. Figure 31Screws7TDVSNORK(Sn<strong>or</strong>kel)Firestop7” Pipe4” (102 mm)ClearanceMin.24” (610 mm)Minimum*DrainGravelFoundation WallWindowWell*A minimum of 24” (610 mm) verticalpipe must be installed whenusing the 7TDVSNORK Kit.BG402a Figure 31 -Below Grade InstallationVenting installationDo not back fill around sn<strong>or</strong>kel.A clearance of at least 4” must be maintainedbetween the sn<strong>or</strong>kel and the soil.If the foundation is recessed, use recess brackets (notsupplied) f<strong>or</strong> securing lower p<strong>or</strong>tion of the sn<strong>or</strong>kel. Fastenbrackets to wall first, then secure to sn<strong>or</strong>kel with self drilling#8 x 1/2 sheet metal screws. It will be necessary toextend vent pipes out as far as the protruding wall face.Figure 32WatertightSeal AroundPIpeFoundationRecessBG401Sn<strong>or</strong>kelWall ScrewsSheet Metal ScrewsFigure 32 -Sn<strong>or</strong>kel installation, recessed foundationBG401VERTICAL Sn<strong>or</strong>kel THROUGH-THE-ROOF APPLICA-TION 2/10/99 djthis gas fireplace has been approved f<strong>or</strong>:• Vertical installations up to 40’ (12 m) in height. Up toa 10’ (3 m) h<strong>or</strong>izontal vent run can be installed withinthe vent system using a maximum of two 90° elbows.Figure 33• Up to two 45° elbows may be used within the h<strong>or</strong>izontalrun. F<strong>or</strong> each 45° elbow used on the h<strong>or</strong>izontal plane,the maximum h<strong>or</strong>izontal length must be reduced by18” (450 mm).Example: Maximum h<strong>or</strong>izontal length:No elbows = 10’ (3 m)1 x 45° elbow = 8.5’ (2.6 m)2 x 45° elbows = 7’ (2.1 m)• A minimum of an 8’ (2.5 m) vertical rise is required.• Two sets of 45° elbow offsets may be used within thevertical sections. From 0 to a maximum of 8’ (2.5 m) ofvent pipe can be used between elbows. Figure 33• 7DVCS supp<strong>or</strong>ts offsets. Figure 37. This applicationwill require that you first determine the roof pitch anduse the appropriate starter kit. (Refer to Venting ComponentsList)• The maximum angular variation allowed in the systemis 270°. Figure 3424 BG402a69D3011Top VentBelow grade installation1/26/00 djt

Venting installationCDVSC7 & CDV7 Series <strong>Gas</strong> Fireplace• F<strong>or</strong> the minimum height of the vent above the highestpoint of penetration through the roof refer to Figure 38,Page 26.Max. Height 40’ (12.2 m)Min. Height 8’ (2.4 m)Max.Height 40’ (12.2 m)Min.Height 8’ (2.4 m)Max. 10’ (3 m)Supp<strong>or</strong>t StrapsEvery 3’ (.9 m)Max. 10’ (3 m)VERTICAL THROUGH-THE-ROOFINSTALLATIONNOTE: F<strong>or</strong> all top vent vertical through-the-roof installations,install the supplied cross-bar flue restrict<strong>or</strong> onto thetop edge of the firebox flue adapter. Figure 351. Locate your fireplace.2. Plumb to center of the (4”) fluecollar from ceiling above andmark position.3. Cut opening equal to 9C\v” x9C\v” (248 x 248 mm).4. Proceed to plumb f<strong>or</strong> additionalopenings through theroof. In all cases, theopening must providea minimum of 1 inch Restrict<strong>or</strong>clearance to the vent FP2304pipe, i.e., the hole mustbe at least 9C\v” x 9C\v” (248 x 248 3/09mm).5. Place fireplace into position.6. Place firestop(s) <strong>or</strong> Attic Insulation Shield into positionand secure. Figure 36Attic InsulationShield(7DV1AIS)FP2304Figure 35 -Vertical Through-the-RoofCDV7 top restrict<strong>or</strong>FP1183Figure 33 -Supp<strong>or</strong>t Straps f<strong>or</strong>H<strong>or</strong>izontal RunsUpper Flo<strong>or</strong>11”(279 mm)1 + 2 + 3 + 4 = 270°Ceiling Installation12341234JoistFP1029FirestopSpacerNails (4)Figure 36 -Place Firestop Spacer(s) and SecureFigure 34 -Maximum Elbow UsageFP11797. Install roof supp<strong>or</strong>t FP1029 (Figure 37) and roof flashing makingsure upper flange is below the shingles. Figure 39attic insulation shield8. Install appropriate pipe sections until the venting isfirestop spacersabove the flashing. Figure 391/28/00 djt69D3011 25

CDVSC7 & CDV7 Series <strong>Gas</strong> Fireplace9. Install st<strong>or</strong>m collar and seal around the pipe.10. Add additional vent lengths f<strong>or</strong> proper height. Figure3911. Apply high temperature sealant to 4” and 7” collarsof vertical vent termination and install.If there is a room above ceiling level, fire stop spacermust be installed on both the bottom ad the top sideof the ceiling joists. If an attic is above ceiling level anAttic Insulation Shield must be installed. The enlargedends of the vent section always face downward.TerminationVentSt<strong>or</strong>m CollarFlashing2 ft.Min.H<strong>or</strong>izontal OverhangVenting installation2 ft. Min.LowestDischargeOpeningH*X12FP19711” Minimum Clearance toCombustiblesConcentricVent PipeTypical RoofSupp<strong>or</strong>tApplicationFigure 37 -FP1184Venting Supp<strong>or</strong>tsTypical roof/ceilingsupp<strong>or</strong>t apps.FP1184Typical CeilingSupp<strong>or</strong>tApplicationFigure 38 -Minimum Chimney ClearanceRoof Pitch H (feet)FP1971 Flat to 6/12 1.0Min chimneyOverclearance6/12 to 7/12 1.25Over 7/12 to 8/12 1.5Over 8/12 to 9/12 2.0Over 9/12 to 10/12 2.5Over 10/12 to 11/12 3.25Over 11/12 to 12/12 4.0*H - Minimum height from roof tolowest discharge opening of vent3 #5 Sheet MetalScrews per JointSealantSt<strong>or</strong>m CollarFigure 39 -Roof FlashingTWL101a26 69D3011TWL101aTwist Lock Pipe2/8/99 djt

fireplace installationCDVSC7 & CDV7 Series <strong>Gas</strong> Fireplacecheck gas typeUse proper gas type f<strong>or</strong> the fireplace you are installing. If you have conflicting gas type, do not installfireplace. See dealer where you purchased the fireplace f<strong>or</strong> proper fireplace f<strong>or</strong> your gas type <strong>or</strong> conversionkit.Install gas piping to fireplace / burner system locationWARNINGA qualified installer <strong>or</strong> service person mustconnect appliance to gas supply. Followall local codes.CAUTIONF<strong>or</strong> propane/LP units, never connect fireplacedirectly to the propane/LP supply. Thisburner system requires an external regulat<strong>or</strong>(not supplied). Install the external regulat<strong>or</strong>between the burner system and propane/LPinstallation items neededBef<strong>or</strong>e installing fireplace and burner system, make sure you have the items listed below.• External regulat<strong>or</strong> • Piping (check local codes) • Sealant (resistant to propane/LP gas)(supplied by installer) • Equipment shutoff valve* • Test gauge connection*• Sediment trap (recommended) • Tee joint • Pipe wrench• approved flexible gas line with gas connect<strong>or</strong> (if allowed by local codes — not provided)* A CSA design-certified equipment shutoff valve with 1/8" NPT tap is an acceptable alternative to test gaugeconnection. Purchase the CSA design-certified equipment shutoff valve from your dealer.F<strong>or</strong> propane/LP connections only, the installer must supply an external regulat<strong>or</strong>. The external regulat<strong>or</strong> will reduceincoming gas pressure. You must reduce incoming gas pressure to between 11 and 13 inches of water. If you do notreduce incoming gas pressure, burner system regulat<strong>or</strong> damage could occur. Install external regulat<strong>or</strong> with the ventpointing down as shown in Figure 40. Pointing the vent down protects it from freezing rain <strong>or</strong> sleet.ExternalRegulat<strong>or</strong>100 lb. (min)Propane/LPSupply TankVent PointingDownCAUTIONUse only new black iron <strong>or</strong> steel pipe. Internallytinned copper <strong>or</strong> copper tubing can be usedper National Fuel Code, Section 2.6.3, providinggas meets hydrogen sulfide limits, and wherepermitted by local codes. <strong>Gas</strong> piping systemmust be sized to provide minimum inletpressure (listed on data plate) at the maximumflow rate (BTU/hr). Undue pressure loss willoccur if the pipe is too small.FP1977When using copper of flex connect<strong>or</strong>s use only fittingsapproved f<strong>or</strong> gas connections. The gas control inlet is3/8" NPT.Figure 40 -External Regulat<strong>or</strong> with Vent Pointing Down(Propane/LP Only)FP1977external regulat<strong>or</strong>69D3011 27

CDVSC7 & CDV7 Series <strong>Gas</strong> Fireplacefireplace installationWARNINGOnly persons licensed to w<strong>or</strong>k with gaspiping may make the necessary gasconnections to this appliance.CAUTIONA manual shutoff valve must be installedupstream of the appliance. Union teeand plugged 1/8” NPT pressure tappingpoint should be installed upstream of theappliance. Figure 41NOTE: The gas line connection may be made using 1/2" rigid tubing <strong>or</strong> an approved flex connect<strong>or</strong>.Since some municipalities have additional local codes it is always best to consult your local auth<strong>or</strong>itiesand the current edition of the National Fuel <strong>Gas</strong> Code ANSI.Z223.1, NFPA54. In Canada CSA-B149(1 <strong>or</strong> 2) Installation Code.A listed manual shutoff valve must be installed upstream ofthe appliance. Union tee and plugged 1/8" NPT pressuretapping point should be installed upstream of the appliance.Figure 41IMPORTANT: Install main gas valve (equipment shutoff valve)in an accessible location. The main gas valve is f<strong>or</strong> turning on<strong>or</strong> shutting off the gas to the fireplace.Check your building codes f<strong>or</strong> any special requirements f<strong>or</strong> locating equipment shutoff valve tofireplaces.Apply pipe joint sealant lightly to male threads. This will prevent excess sealant from going into pipe.Excess sealant in pipe could result in clogged burner system valve.We recommend that you install a sediment trap/drip leg in supply line as shown in Figure 41. Locatesediment trap/drip leg where it is within reach f<strong>or</strong> cleaning. Install in piping system between fuelsupply and burner system. Locate sediment trap/drip leg where trapped matter is not likely to freeze.A sediment trap collects moisture and contaminants and keeps them from going into the burnersystem gas controls. If sediment trap/drip leg is not installed <strong>or</strong> is installed wrong, burner systemmay not run properly.CAUTIONUse pipe joint sealant that is resistant toliquid petroleum (LP) gas.Approved Flexible<strong>Gas</strong> LineCSA Design-Certified Equipment Shutoff Valvewith 1/8" NPT Tap*Sediment Trap/Drip LegTee JointPipe NippleNatural <strong>Gas</strong>From <strong>Gas</strong> Meter(4.5" w.c. to 10.5" w.c. Pressure)Propane/LPFrom External Regulat<strong>or</strong>(11" w.c. to 13" w.c. Pressure)Cap3" MinimumFigure 41 -<strong>Gas</strong> ConnectionFP1978gas connection28 69D3011

CHECK GAS PRESSURE & Electrical installationCDVSC7 & CDV7 Series <strong>Gas</strong> Fireplace1. Check gas type. The gas supply must be the same asstated on the appliance’s rating decal. If the gas supplyis different from the fireplace, STOP! Do not install theappliance. Contact your dealer immediately.2. To ease installation, a 30" (mm) flex line with manual shutoffvalve has been provided with this appliance. Installand attach 1/2" gas line onto shut-off valve.3. After completing gas line connection, purge air fromgas line and test all gas joints from the gas meterto the fireplace f<strong>or</strong> leaks. Use a solution of 50/50water and soap <strong>or</strong> a gas sniffer.4. To adjust flame height, turn HI/LO knob to HI to getmaximum pressure to burner. Turn HI/LO knob toLO to get minimum pressure.5. To check gas pressures at valve, turn capturedscrew counter clockwise 2 <strong>or</strong> 3 turns and then placetubing to pressure gauge over test point. Turn unitto high. Figure 42. After taking pressure reading,be sure and turn captured screw clockwise firmlyto reseal. Do not over t<strong>or</strong>que. Check test points f<strong>or</strong>gas leaks.Electrical WiringPressureTest “IN”PressureTest “OUT”HI/LO KnobPilot Adjustment ScrewFP1979Figure 42 -<strong>Gas</strong> Pressure Check at <strong>Gas</strong> ValveFP1979Do not Millivolt use open gas flame valveto check f<strong>or</strong> gasleaks.This fireplace will w<strong>or</strong>k without any electrical supply. Electricity is only needed to operate blower.NOTE: If installed in mobile home, fireplace must be bolted securely to flo<strong>or</strong>.WARNINGWARNINGElectrical connections should onlybe perf<strong>or</strong>med by a qualified, licensedelectrician. Main power must be off whenconnecting to main electrical power supply<strong>or</strong> perf<strong>or</strong>ming service. All wiring shall bein compliance with all local, city and statecodes. The appliance, when installed, mustbe electrically grounded in acc<strong>or</strong>dancewith local codes <strong>or</strong> in the absence of localcodes, with the National Electrical CodeANSI/NFPA 70 (latest edition) and CanadianElectrical Code, CSA C22.1.CAUTIONLabel all wires bef<strong>or</strong>e disconnecting whenservicing controls. Wiring err<strong>or</strong>s can causeimproper and dangerous operation.Verify proper operation after servicing.69D3011 29