Final Program EXPRES 2012 - Conferences

Final Program EXPRES 2012 - Conferences

Final Program EXPRES 2012 - Conferences

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

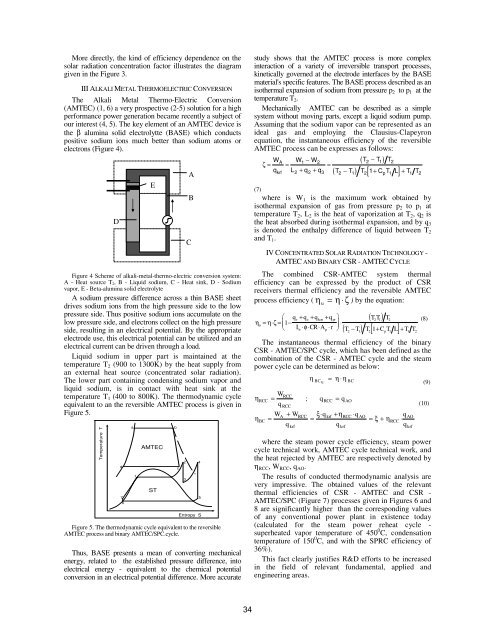

More directly, the kind of efficiency dependence on thesolar radiation concentration factor illustrates the diagramgiven in the Figure 3.III ALKALI METAL THERMOELECTRIC CONVERSIONThe Alkali Metal Thermo-Electric Conversion(AMTEC) (1, 6) a very prospective (2-5) solution for a highperformance power generation became recently a subject ofour interest (4, 5). The key element of an AMTEC device isthe β alumina solid electrolytte (BASE) which conductspositive sodium ions much better than sodium atoms orelectrons (Figure 4).Figure 4 Scheme of alkali-metal-thermo-electric conversion system:A - Heat source T 2, B - Liquid sodium, C - Heat sink, D - Sodiumvapor, E - Beta-alumina solid electrolyteA sodium pressure difference across a thin BASE sheetdrives sodium ions from the high pressure side to the lowpressure side. Thus positive sodium ions accumulate on thelow pressure side, and electrons collect on the high pressureside, resulting in an electrical potential. By the appropriateelectrode use, this electrical potential can be utilized and anelectrical current can be driven through a load.Liquid sodium in upper part is maintained at thetemperature T 2 (900 to 1300K) by the heat supply froman external heat source (concentrated solar radiation).The lower part containing condensing sodium vapor andliquid sodium, is in contact with heat sink at thetemperature T 1 (400 to 800K). The thermodynamic cycleequivalent to an the reversible AMTEC process is given inFigure 5.Temperature TDd76a1AMTECSTbc2345Entropy SFigure 5. The thermodynamic cycle equivalent to the reversibleAMTEC process and binary AMTEC/SPC.cycle.EThus, BASE presents a mean of converting mechanicalenergy, related to the established pressure difference, intoelectrical energy - equivalent to the chemical potentialconversion in an electrical potential difference. More accurateABCstudy shows that the AMTEC process is more complexinteraction of a variety of irreversible transport processes,kinetically governed at the electrode interfaces by the BASEmaterial's specific features. The BASE process described as anisothermal expansion of sodium from pressure p 2 to p 1 at thetemperature T 2 .Mechanically AMTEC can be described as a simplesystem without moving parts, except a liquid sodium pump.Assuming that the sodium vapor can be represented as anideal gas and employing the Clausius-Clapeyronequation, the instantaneous efficiency of the reversibleAMTEC process can be expresses as follows:W W − W( T − T ) TA 1 22 1 2ζ = ==q L + q + q T − T T 1+ C T L + T Tkrf2 2 3( ) [ p ]2 1 2 1 1 2(7)where is W 1 is the maximum work obtained byisothermal expansion of gas from pressure p 2 to p 1 attemperature T 2 , L 2 is the heat of vaporization at T 2 , q 2 isthe heat absorbed during isothermal expansion, and by q 3is denoted the enthalpy difference of liquid between T 2and T 1 .IV CONCENTRATED SOLAR RADIATION TECHNOLOGY -AMTEC AND BINARY CSR - AMTEC CYCLEThe combined CSR-AMTEC system thermalefficiency can be expressed by the product of CSRreceivers thermal efficiency and the reversible AMTECprocess efficiency ( ηu = η ⋅ ζ ) by the equation:⎛ q + q + q + qηu= η⋅ ζ = ⎜1−⎝ Ib⋅φ⋅CR ⋅Ap⋅rr z kon pr( T T )⎞T⎠⎟ ⋅ 2 1 2 (8)T − T T + C T L + T T( ) [ 1p ]2 1 2 1 1 2The instantaneous thermal efficiency of the binaryCSR - AMTEC/SPC cycle, which has been defined as thecombination of the CSR - AMTEC cycle and the steampower cycle can be determined as below:ηηRCCBCARCCkrfRCCηBC u= η ⋅ ηWRCC= ; q RCC = qqW=+ WqBCAOξ q krf ηRCC qAOq= ⋅ + ⋅ = ξ + ηRCC⋅qqkrfAOkrf(9)(10)where the steam power cycle efficiency, steam powercycle technical work, AMTEC cycle technical work, andthe heat rejected by AMTEC are respectively denoted byη RCC , W RCC , q AO .The results of conducted thermodynamic analysis arevery impressive. The obtained values of the relevantthermal efficiencies of CSR - AMTEC and CSR -AMTEC/SPC (Figure 7) processes given in Figures 6 and8 are significantly higher than the corresponding valuesof any conventional power plant in existence today(calculated for the steam power reheat cycle -superheated vapor temperature of 450 0 C, condensationtemperature of 150 0 C, and with the SPRC efficiency of36%).This fact clearly justifies R&D efforts to be increasedin the field of relevant fundamental, applied andengineering areas.34