- Page 2:

HOW TO USE THIS MANUALTO LOCATE WHA

- Page 5 and 6:

GENERAL INFORMATIONCONTENTS1INFORMA

- Page 8 and 9:

1-3 GENERAL INFORMATIONSERIAL NUMBE

- Page 10 and 11:

1-5 GENERAL INFORMATION◉ ENGINE C

- Page 12 and 13:

1-7 GENERAL INFORMATIONEXTERIOR ILL

- Page 16 and 17:

2-1 PERIODIC MAINTENANCEPERIODIC MA

- Page 18 and 19:

2-3 PERIODIC MAINTENANCEMAINTENANCE

- Page 20 and 21:

2-5 PERIODIC MAINTENANCEVALVE CLEAR

- Page 22 and 23: 2-7 PERIODIC MAINTENANCE● If the

- Page 24 and 25: 2-9 PERIODIC MAINTENANCECAUTIONTo a

- Page 26 and 27: 2-11 PERIODIC MAINTENANCECAUTIONNec

- Page 28 and 29: 2-13 PERIODIC MAINTENANCE5. Install

- Page 30 and 31: 2-15 PERIODIC MAINTENANCE● Remove

- Page 32 and 33: 2-17 PERIODIC MAINTENANCE▣ AIR BL

- Page 34 and 35: 2-19 PERIODIC MAINTENANCESTEERINGIn

- Page 36 and 37: 2-21 PERIODIC MAINTENANCE● Count

- Page 38 and 39: 2-23 PERIODIC MAINTENANCESUSPENSION

- Page 40 and 41: 2-25 PERIODIC MAINTENANCEOIL PRESSU

- Page 42 and 43: 3-1 ENGINEENGINE REMOVAL ANDREMOUNT

- Page 44 and 45: 3-3 ENGINE● Remove the carburetor

- Page 46 and 47: 3-5 ENGINE● Loosen the muffler co

- Page 48 and 49: 3-7 ENGINE● Tighten the exhaust p

- Page 50 and 51: 3-9 ENGINEENGINE DISASSEMBLY● Rem

- Page 52 and 53: 3-11 ENGINE● Turn the magneto rot

- Page 54 and 55: 3-13 ENGINE● Place a clean rag ov

- Page 56 and 57: 3-15 ENGINE● Remove the clutch pu

- Page 58 and 59: 3-17 ENGINE● Remove the gearshift

- Page 60 and 61: 3-19 ENGINE● Remove the cam chain

- Page 62 and 63: 3-21 ENGINE● Remove the crankshaf

- Page 64 and 65: 3-23 ENGINE● Install the valve sp

- Page 66 and 67: 3-25 ENGINE▣ VALVE HEAD RADIAL RU

- Page 68 and 69: 3-27 ENGINE▣ CAMSHAFT JOURNAL WEA

- Page 70 and 71: 3-29 ENGINE▣ CAM CHAIN AND CAM CH

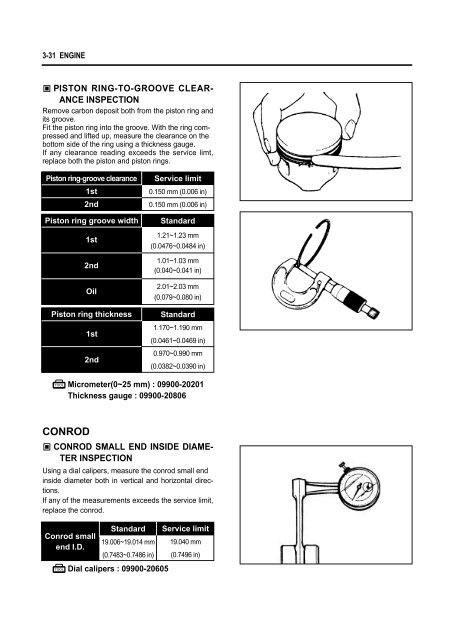

- Page 74 and 75: 3-33 ENGINECRANK BALANCER AND BALAN

- Page 76 and 77: 3-35 ENGINECLUTCH▣ CLUTCH DRIVE P

- Page 78 and 79: 3-37 ENGINETRANSMISSION▣ DISASSEM

- Page 80 and 81: 3-39 ENGINE▣ REASSEMBLYReassemble

- Page 82 and 83: 3-41 ENGINE● Remove the oil strai

- Page 84 and 85: 3-43 ENGINE▣ CLUTCH RELEASE CAMSH

- Page 86 and 87: 3-45 ENGINE◉ GEARSHIFT CAM, FORK

- Page 88 and 89: 13-47 ENGINE◉ GEAR POSITION SWITC

- Page 90 and 91: 3-49 ENGINE● Install the gearshif

- Page 92 and 93: 23-51 ENGINE● Bend the tongue of

- Page 94 and 95: 3-53 ENGINE◉ PISTON RING● Insta

- Page 96 and 97: 3-55 ENGINE● Install the cam chai

- Page 98 and 99: 3-57 ENGINE21st pin15th pin31

- Page 100 and 101: 3-59 ENGINE◉ CAM CHAIN TENSION AD

- Page 102 and 103: FUEL SYSTEMCONTENTSFUEL TANK……

- Page 104 and 105: FUEL SYSTEM 4-2◉ REMOUNTINGRemoun

- Page 106 and 107: FUEL SYSTEM 4-4◉ LOCATION OF CARB

- Page 108 and 109: 7FUEL SYSTEM 4-6● Remove the spri

- Page 110 and 111: FUEL SYSTEM 4-8● Remove the main

- Page 112 and 113: FUEL SYSTEM 4-10● Align the hole

- Page 114 and 115: 5-1 COOLING SYSTEMENGINE COOLANTAt

- Page 116 and 117: 5-3 COOLING SYSTEM● Disconnect re

- Page 118 and 119: 5-5 COOLING SYSTEMCOOLING FAN◉ IN

- Page 120: 5-7 COOLING SYSTEM◉ INSTALLATIONI

- Page 123 and 124:

COOLING SYSTEM 5-10● Keep on heat

- Page 125 and 126:

COOLING SYSTEM 5-12● Remove the c

- Page 127 and 128:

COOLING SYSTEM 5-14▣ BEARING CASE

- Page 129:

COOLING SYSTEM 5-16OIL TANK AND HOS

- Page 132 and 133:

5-19 COOLING SYSTEM● Install the

- Page 135 and 136:

ELECTRICAL SYSTEM 6-21314121512 Bat

- Page 138 and 139:

6-5 ELECTRICAL SYSTEM▣ IGNITION C

- Page 140 and 141:

6-7 ELECTRICAL SYSTEMCHARGING SYSTE

- Page 142 and 143:

6-9 ELECTRICAL SYSTEMSTARTER SYSTEM

- Page 144 and 145:

6-11 ELECTRICAL SYSTEM◉ STARTER M

- Page 146 and 147:

6-13 ELECTRICAL SYSTEMLAMPS◉ HEAD

- Page 148 and 149:

6-15 ELECTRICAL SYSTEM◉ COMBINATI

- Page 150 and 151:

6-17 ELECTRICAL SYSTEMCapSeal3 Pour

- Page 152 and 153:

CHASSISCONTENTSEXTERIOR PARTS …

- Page 154 and 155:

CHASSIS 7-2

- Page 156 and 157:

CHASSIS 7-4● Remove the four stee

- Page 158 and 159:

CHASSIS 7-6◉ REMOUNTINGRemount th

- Page 161:

7-9 CHASSIS▣ REAR WHEEL HUB● Re

- Page 164 and 165:

CHASSIS 7-12▣ FRONT WHEEL● Inst

- Page 166 and 167:

CHASSIS 7-14◉ BRAKE PAD REPLACEME

- Page 168 and 169:

32CHASSIS 7-16● Remove the brake

- Page 170 and 171:

CHASSIS 7-18◉ BRAKE DISK REMOVAL

- Page 172 and 173:

CHASSIS 7-20◉ MASTER CYLINDER INS

- Page 174 and 175:

CHASSIS 7-22◉ REMOVAL● Remove t

- Page 176 and 177:

CHASSIS 7-24◉ INSPECTION AND DISA

- Page 178 and 179:

CHASSIS 7-26◉ REASSEMBLY AND REMO

- Page 180 and 181:

CHASSIS 7-28NOTEWhen installing the

- Page 182 and 183:

CHASSIS 7-30STEERING◉ CONSTRUCTIO

- Page 184 and 185:

CHASSIS 7-32▣ STEERING SHAFT AND

- Page 186 and 187:

CHASSIS 7-34● Remove the steering

- Page 188 and 189:

CHASSIS 7-36◉ REASSEMBLY AND REMO

- Page 190 and 191:

CHASSIS 7-38with a narrow width hav

- Page 192 and 193:

CHASSIS 7-40◉ TOE-IN ADJUSTMENTAd

- Page 194 and 195:

CHASSIS 7-42◉ BRAKE PAD REPLACEME

- Page 196 and 197:

CHASSIS 7-44◉ BRAKE CALIPER REMOV

- Page 198 and 199:

21CHASSIS 7-46◉ BRAKE CALIPER REA

- Page 200 and 201:

CHASSIS 7-48● Connect the parking

- Page 202 and 203:

CHASSIS 7-50◉ MASTER CYLINDER REA

- Page 204 and 205:

CHASSIS 7-52● Remove the reverse

- Page 206 and 207:

CHASSIS 7-54REAR SHOCK ABSORBER◉

- Page 208 and 209:

CHASSIS 7-56◉ REAR SHOCK ABSORBER

- Page 210 and 211:

CHASSIS 7-58▣ DAMPING FORCE ADJUS

- Page 212 and 213:

CHASSIS 7-60◉ REMOVAL▣ CUSHION

- Page 214 and 215:

CHASSIS 7-62◉ INSPECTION AND DISA

- Page 216 and 217:

CHASSIS 7-64▣ CUSHION LEVER AND R

- Page 218 and 219:

CHASSIS 7-66REAR AXLE◉ CONSTRUCTI

- Page 220 and 221:

CHASSIS 7-68● Remove the brake di

- Page 222 and 223:

CHASSIS 7-70▣ REASSEMBLY AND REMO

- Page 224 and 225:

CHASSIS 7-72● Apply SUPER GREASE

- Page 226 and 227:

SERVICING INFORMATIONCONTENTSTROUBL

- Page 228 and 229:

SERVICING INFORMATION 8-2ComplaintN

- Page 230 and 231:

SERVICING INFORMATION 8-4◉ CARBUR

- Page 232 and 233:

SERVICING INFORMATION 8-6◉ BATTER

- Page 234 and 235:

SERVICING INFORMATION 8-8◉ BRAKES

- Page 236 and 237:

SERVICING INFORMATION 8-10Special t

- Page 238 and 239:

SERVICING INFORMATION 8-12TIGHTENIN

- Page 240 and 241:

SERVICING INFORMATION 8-14SERVICE D

- Page 242 and 243:

SERVICING INFORMATION 8-16◉ OIL P

- Page 244 and 245:

SERVICING INFORMATION 8-18◉ TRANS

- Page 246 and 247:

SERVICING INFORMATION 8-20◉ THERM

- Page 248 and 249:

SERVICING INFORMATION 8-22◉ WATTA

- Page 250 and 251:

SERVICING INFORMATION 8-24◉ BRAKE

- Page 252 and 253:

WIRE AND CABLE ROUTINGSERVICING INF

- Page 254 and 255:

SERVICING INFORMATION 8-28

- Page 256 and 257:

SERVICING INFORMATION 8-30

- Page 258 and 259:

SERVICING INFORMATION 8-32WIRING DI

- Page 260 and 261:

MEASURINGTAPPETCLEARANCE (mm)0.10 ~