warning - Docs.hvacpartners.com

warning - Docs.hvacpartners.com

warning - Docs.hvacpartners.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

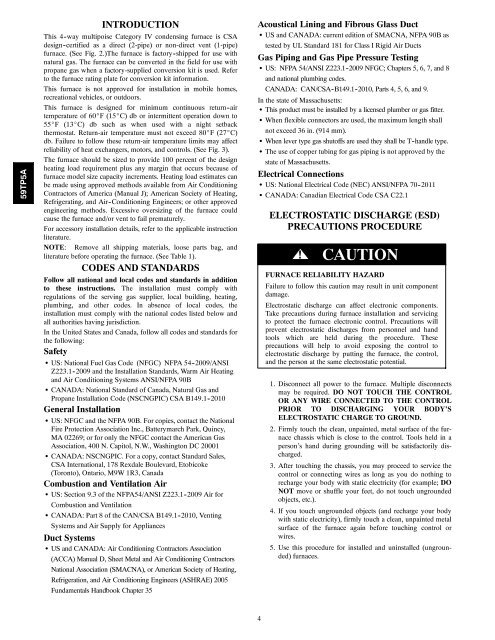

59TP5AINTRODUCTIONThis 4 -way multipoise Category IV condensing furnace is CSAdesign -certified as a direct (2-pipe) or non-direct vent (1-pipe)furnace. (See Fig. 2.)The furnace is factory -shipped for use withnatural gas. The furnace can be converted in the field for use withpropane gas when a factory-supplied conversion kit is used. Referto the furnace rating plate for conversion kit information.This furnace is not approved for installation in mobile homes,recreational vehicles, or outdoors.This furnace is designed for minimum continuous return -airtemperature of 60_F (15_C) db or intermittent operation down to55_F (13_C) db such as when used with a night setbackthermostat. Return-air temperature must not exceed 80_F (27_C)db. Failure to follow these return-air temperature limits may affectreliability of heat exchangers, motors, and controls. (See Fig. 3).The furnace should be sized to provide 100 percent of the designheating load requirement plus any margin that occurs because offurnace model size capacity increments. Heating load estimates canbe made using approved methods available from Air ConditioningContractors of America (Manual J); American Society of Heating,Refrigerating, and Air-Conditioning Engineers; or other approvedengineering methods. Excessive oversizing of the furnace couldcause the furnace and/or vent to fail prematurely.For accessory installation details, refer to the applicable instructionliterature.NOTE: Remove all shipping materials, loose parts bag, andliterature before operating the furnace. (See Table 1).CODES AND STANDARDSFollow all national and local codes and standards in additionto these instructions. The installation must <strong>com</strong>ply withregulations of the serving gas supplier, local building, heating,plumbing, and other codes. In absence of local codes, theinstallation must <strong>com</strong>ply with the national codes listed below andall authorities having jurisdiction.In the United States and Canada, follow all codes and standards forthe following:SafetyS US: National Fuel Gas Code (NFGC) NFPA 54 -2009/ANSIZ223.1 -2009 and the Installation Standards, Warm Air Heatingand Air Conditioning Systems ANSI/NFPA 90BS CANADA: National Standard of Canada, Natural Gas andPropane Installation Code (NSCNGPIC) CSA B149.1 -2010General InstallationS US: NFGC and the NFPA 90B. For copies, contact the NationalFire Protection Association Inc., Batterymarch Park, Quincy,MA 02269; or for only the NFGC contact the American GasAssociation, 400 N. Capitol, N.W., Washington DC 20001S CANADA: NSCNGPIC. For a copy, contact Standard Sales,CSA International, 178 Rexdale Boulevard, Etobicoke(Toronto), Ontario, M9W 1R3, CanadaCombustion and Ventilation AirS US: Section 9.3 of the NFPA54/ANSI Z223.1 -2009 Air forCombustion and VentilationS CANADA: Part 8 of the CAN/CSA B149.1 -2010, VentingSystems and Air Supply for AppliancesDuct SystemsS US and CANADA: Air Conditioning Contractors Association(ACCA) Manual D, Sheet Metal and Air Conditioning ContractorsNational Association (SMACNA), or American Society of Heating,Refrigeration, and Air Conditioning Engineers (ASHRAE) 2005Fundamentals Handbook Chapter 35Acoustical Lining and Fibrous Glass DuctS US and CANADA: current edition of SMACNA, NFPA 90B astested by UL Standard 181 for Class I Rigid Air DuctsGas Piping and Gas Pipe Pressure TestingS US: NFPA 54/ANSI Z223.1 -2009 NFGC; Chapters 5, 6, 7, and 8and national plumbing codes.CANADA: CAN/CSA-B149.1 -2010, Parts 4, 5, 6, and 9.In the state of Massachusetts:S This product must be installed by a licensed plumber or gas fitter.S When flexible connectors are used, the maximum length shallnot exceed 36 in. (914 mm).S When lever type gas shutoffs are used they shall be T -handle type.S The use of copper tubing for gas piping is not approved by thestate of Massachusetts.Electrical ConnectionsS US: National Electrical Code (NEC) ANSI/NFPA 70 -2011S CANADA: Canadian Electrical Code CSA C22.1ELECTROSTATIC DISCHARGE (ESD)PRECAUTIONS PROCEDURE!CAUTIONFURNACE RELIABILITY HAZARDFailure to follow this caution may result in unit <strong>com</strong>ponentdamage.Electrostatic discharge can affect electronic <strong>com</strong>ponents.Take precautions during furnace installation and servicingto protect the furnace electronic control. Precautions willprevent electrostatic discharges from personnel and handtools which are held during the procedure. Theseprecautions will help to avoid exposing the control toelectrostatic discharge by putting the furnace, the control,and the person at the same electrostatic potential.1. Disconnect all power to the furnace. Multiple disconnectsmay be required. DO NOT TOUCH THE CONTROLOR ANY WIRE CONNECTED TO THE CONTROLPRIOR TO DISCHARGING YOUR BODY’SELECTROSTATIC CHARGE TO GROUND.2. Firmly touch the clean, unpainted, metal surface of the furnacechassis which is close to the control. Tools held in aperson’s hand during grounding will be satisfactorily discharged.3. After touching the chassis, you may proceed to service thecontrol or connecting wires as long as you do nothing torecharge your body with static electricity (for example; DONOT move or shuffle your feet, do not touch ungroundedobjects, etc.).4. If you touch ungrounded objects (and recharge your bodywith static electricity), firmly touch a clean, unpainted metalsurface of the furnace again before touching control orwires.5. Use this procedure for installed and uninstalled (ungrounded)furnaces.4