- Page 2:

Engineering Geology

- Page 6:

Engineering Geology Second Edition

- Page 10:

Preface As noted in the Preface to

- Page 14:

Contents 1. Rock Types and Stratigr

- Page 18:

Contents Field Instrumentation 344

- Page 22:

Chapter 1 Rock Types and Stratigrap

- Page 26:

Chapter 1 several tens of metres bu

- Page 30:

Chapter 1 Figure 1.4 Distribution o

- Page 34:

Chapter 1 Figure 1.5 Lapilli near C

- Page 38:

Chapter 1 Figure 1.7 (a) Ropy or pa

- Page 42:

Chapter 1 Figure 1.8 Columnar joint

- Page 46:

Chapter 1 Figure 1.9 Pegmatite vein

- Page 50:

Chapter 1 Figure 1.10 Thin section

- Page 54:

Chapter 1 Figure 1.11 An old quarry

- Page 58:

Chapter 1 a b Figure 1.13 (a) Gneis

- Page 62:

Chapter 1 and the types of country

- Page 66:

Chapter 1 A variety of minerals suc

- Page 70:

Chapter 1 metasomatic activity is c

- Page 74:

Chapter 1 derived by partial intras

- Page 78:

Chapter 1 character (are they irreg

- Page 82:

Chapter 1 the top. Individual grade

- Page 86:

Chapter 1 Figure 1.20 Thin section

- Page 90:

Chapter 1 Montmorillonite [(Mg,Al)

- Page 94:

Chapter 1 Figure 1.22 Salt teepees

- Page 98:

Chapter 1 The extent and regularity

- Page 102:

Chapter 1 the lowest bed in the upp

- Page 106:

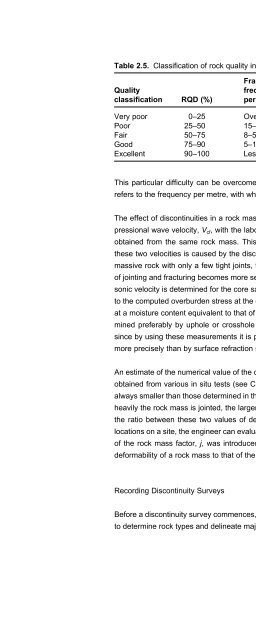

Table 1.1. The geological timescale

- Page 110: Chapter 1 The principal way in whic

- Page 114: Chapter 2 Geological Structures The

- Page 118: Chapter 2 (b) Figure 2.2 (a) Block

- Page 122: Chapter 2 (b) Figure 2.4 (a) Types

- Page 126: Chapter 2 Figure 2.6 Chevron fold i

- Page 130: Chapter 2 direction of extension. T

- Page 134: Chapter 2 Figure 2.9 Types of fault

- Page 138: Chapter 2 Figure 2.11 (a) Repetitio

- Page 142: Chapter 2 side of a fault are of di

- Page 146: Chapter 2 Figure 2.14 Geometric ori

- Page 150: Chapter 2 As joints represent surfa

- Page 154: Chapter 2 (several metres). The int

- Page 158: Chapter 2 Strength of Discontinuous

- Page 164: E n g i n e e r i n g G e o l o g y

- Page 168: E n g i n e e r i n g G e o l o g y

- Page 172: E n g i n e e r i n g G e o l o g y

- Page 176: E n g i n e e r i n g G e o l o g y

- Page 180: E n g i n e e r i n g G e o l o g y

- Page 184: E n g i n e e r i n g G e o l o g y

- Page 188: E n g i n e e r i n g G e o l o g y

- Page 192: E n g i n e e r i n g G e o l o g y

- Page 196: E n g i n e e r i n g G e o l o g y

- Page 200: E n g i n e e r i n g G e o l o g y

- Page 204: E n g i n e e r i n g G e o l o g y

- Page 208: E n g i n e e r i n g G e o l o g y

- Page 212:

E n g i n e e r i n g G e o l o g y

- Page 216:

E n g i n e e r i n g G e o l o g y

- Page 220:

E n g i n e e r i n g G e o l o g y

- Page 224:

E n g i n e e r i n g G e o l o g y

- Page 228:

E n g i n e e r i n g G e o l o g y

- Page 232:

E n g i n e e r i n g G e o l o g y

- Page 236:

E n g i n e e r i n g G e o l o g y

- Page 240:

E n g i n e e r i n g G e o l o g y

- Page 244:

E n g i n e e r i n g G e o l o g y

- Page 248:

E n g i n e e r i n g G e o l o g y

- Page 252:

E n g i n e e r i n g G e o l o g y

- Page 256:

E n g i n e e r i n g G e o l o g y

- Page 260:

E n g i n e e r i n g G e o l o g y

- Page 264:

Figure 3.29 Block diagram of a glac

- Page 268:

E n g i n e e r i n g G e o l o g y

- Page 272:

E n g i n e e r i n g G e o l o g y

- Page 276:

E n g i n e e r i n g G e o l o g y

- Page 280:

E n g i n e e r i n g G e o l o g y

- Page 284:

E n g i n e e r i n g G e o l o g y

- Page 288:

E n g i n e e r i n g G e o l o g y

- Page 292:

E n g i n e e r i n g G e o l o g y

- Page 296:

E n g i n e e r i n g G e o l o g y

- Page 300:

E n g i n e e r i n g G e o l o g y

- Page 304:

E n g i n e e r i n g G e o l o g y

- Page 308:

E n g i n e e r i n g G e o l o g y

- Page 312:

E n g i n e e r i n g G e o l o g y

- Page 316:

E n g i n e e r i n g G e o l o g y

- Page 320:

This page intentionally left blank

- Page 324:

E n g i n e e r i n g G e o l o g y

- Page 328:

E n g i n e e r i n g G e o l o g y

- Page 332:

E n g i n e e r i n g G e o l o g y

- Page 336:

E n g i n e e r i n g G e o l o g y

- Page 340:

E n g i n e e r i n g G e o l o g y

- Page 344:

162 Table 4.4. Relative values of p

- Page 348:

E n g i n e e r i n g G e o l o g y

- Page 352:

E n g i n e e r i n g G e o l o g y

- Page 356:

E n g i n e e r i n g G e o l o g y

- Page 360:

E n g i n e e r i n g G e o l o g y

- Page 364:

E n g i n e e r i n g G e o l o g y

- Page 368:

E n g i n e e r i n g G e o l o g y

- Page 372:

E n g i n e e r i n g G e o l o g y

- Page 376:

E n g i n e e r i n g G e o l o g y

- Page 380:

E n g i n e e r i n g G e o l o g y

- Page 384:

E n g i n e e r i n g G e o l o g y

- Page 388:

E n g i n e e r i n g G e o l o g y

- Page 392:

E n g i n e e r i n g G e o l o g y

- Page 396:

E n g i n e e r i n g G e o l o g y

- Page 400:

E n g i n e e r i n g G e o l o g y

- Page 404:

E n g i n e e r i n g G e o l o g y

- Page 408:

E n g i n e e r i n g G e o l o g y

- Page 412:

E n g i n e e r i n g G e o l o g y

- Page 416:

E n g i n e e r i n g G e o l o g y

- Page 420:

E n g i n e e r i n g G e o l o g y

- Page 424:

E n g i n e e r i n g G e o l o g y

- Page 428:

E n g i n e e r i n g G e o l o g y

- Page 432:

E n g i n e e r i n g G e o l o g y

- Page 436:

E n g i n e e r i n g G e o l o g y

- Page 440:

E n g i n e e r i n g G e o l o g y

- Page 444:

E n g i n e e r i n g G e o l o g y

- Page 448:

E n g i n e e r i n g G e o l o g y

- Page 452:

E n g i n e e r i n g G e o l o g y

- Page 456:

E n g i n e e r i n g G e o l o g y

- Page 460:

E n g i n e e r i n g G e o l o g y

- Page 464:

E n g i n e e r i n g G e o l o g y

- Page 468:

E n g i n e e r i n g G e o l o g y

- Page 472:

E n g i n e e r i n g G e o l o g y

- Page 476:

E n g i n e e r i n g G e o l o g y

- Page 480:

E n g i n e e r i n g G e o l o g y

- Page 484:

E n g i n e e r i n g G e o l o g y

- Page 488:

E n g i n e e r i n g G e o l o g y

- Page 492:

E n g i n e e r i n g G e o l o g y

- Page 496:

E n g i n e e r i n g G e o l o g y

- Page 500:

E n g i n e e r i n g G e o l o g y

- Page 504:

E n g i n e e r i n g G e o l o g y

- Page 508:

E n g i n e e r i n g G e o l o g y

- Page 512:

E n g i n e e r i n g G e o l o g y

- Page 516:

248 Table 5.21. Some properties of

- Page 520:

E n g i n e e r i n g G e o l o g y

- Page 524:

252 Table 5.22. Rock type classific

- Page 528:

E n g i n e e r i n g G e o l o g y

- Page 532:

E n g i n e e r i n g G e o l o g y

- Page 536:

E n g i n e e r i n g G e o l o g y

- Page 540:

E n g i n e e r i n g G e o l o g y

- Page 544:

E n g i n e e r i n g G e o l o g y

- Page 548:

E n g i n e e r i n g G e o l o g y

- Page 552:

E n g i n e e r i n g G e o l o g y

- Page 556:

E n g i n e e r i n g G e o l o g y

- Page 560:

E n g i n e e r i n g G e o l o g y

- Page 564:

272 Table 5.33. Some physical prope

- Page 568:

274 Table 5.34. Geomechanical prope

- Page 572:

E n g i n e e r i n g G e o l o g y

- Page 576:

E n g i n e e r i n g G e o l o g y

- Page 580:

280 Table 6.1. Some properties of B

- Page 584:

282 Table 6.2. Some properties of B

- Page 588:

E n g i n e e r i n g G e o l o g y

- Page 592:

E n g i n e e r i n g G e o l o g y

- Page 596:

E n g i n e e r i n g G e o l o g y

- Page 600:

E n g i n e e r i n g G e o l o g y

- Page 604:

E n g i n e e r i n g G e o l o g y

- Page 608:

E n g i n e e r i n g G e o l o g y

- Page 612:

E n g i n e e r i n g G e o l o g y

- Page 616:

E n g i n e e r i n g G e o l o g y

- Page 620:

E n g i n e e r i n g G e o l o g y

- Page 624:

E n g i n e e r i n g G e o l o g y

- Page 628:

E n g i n e e r i n g G e o l o g y

- Page 632:

E n g i n e e r i n g G e o l o g y

- Page 636:

E n g i n e e r i n g G e o l o g y

- Page 640:

This page intentionally left blank

- Page 644:

E n g i n e e r i n g G e o l o g y

- Page 648:

E n g i n e e r i n g G e o l o g y

- Page 652:

E n g i n e e r i n g G e o l o g y

- Page 656:

E n g i n e e r i n g G e o l o g y

- Page 660:

E n g i n e e r i n g G e o l o g y

- Page 664:

E n g i n e e r i n g G e o l o g y

- Page 668:

E n g i n e e r i n g G e o l o g y

- Page 672:

E n g i n e e r i n g G e o l o g y

- Page 676:

E n g i n e e r i n g G e o l o g y

- Page 680:

E n g i n e e r i n g G e o l o g y

- Page 684:

E n g i n e e r i n g G e o l o g y

- Page 688:

E n g i n e e r i n g G e o l o g y

- Page 692:

E n g i n e e r i n g G e o l o g y

- Page 696:

E n g i n e e r i n g G e o l o g y

- Page 700:

E n g i n e e r i n g G e o l o g y

- Page 704:

E n g i n e e r i n g G e o l o g y

- Page 708:

E n g i n e e r i n g G e o l o g y

- Page 712:

E n g i n e e r i n g G e o l o g y

- Page 716:

E n g i n e e r i n g G e o l o g y

- Page 720:

E n g i n e e r i n g G e o l o g y

- Page 724:

E n g i n e e r i n g G e o l o g y

- Page 728:

E n g i n e e r i n g G e o l o g y

- Page 732:

E n g i n e e r i n g G e o l o g y

- Page 736:

E n g i n e e r i n g G e o l o g y

- Page 740:

E n g i n e e r i n g G e o l o g y

- Page 744:

E n g i n e e r i n g G e o l o g y

- Page 748:

E n g i n e e r i n g G e o l o g y

- Page 752:

E n g i n e e r i n g G e o l o g y

- Page 756:

E n g i n e e r i n g G e o l o g y

- Page 760:

E n g i n e e r i n g G e o l o g y

- Page 764:

372 Table 7.7a. Excerpts from the e

- Page 768:

374 Table 7.7b. Key to the engineer

- Page 772:

E n g i n e e r i n g G e o l o g y

- Page 776:

E n g i n e e r i n g G e o l o g y

- Page 780:

E n g i n e e r i n g G e o l o g y

- Page 784:

E n g i n e e r i n g G e o l o g y

- Page 788:

E n g i n e e r i n g G e o l o g y

- Page 792:

E n g i n e e r i n g G e o l o g y

- Page 796:

E n g i n e e r i n g G e o l o g y

- Page 800:

390 Table 8.1. Modified Mercalli Sc

- Page 804:

E n g i n e e r i n g G e o l o g y

- Page 808:

E n g i n e e r i n g G e o l o g y

- Page 812:

E n g i n e e r i n g G e o l o g y

- Page 816:

E n g i n e e r i n g G e o l o g y

- Page 820:

E n g i n e e r i n g G e o l o g y

- Page 824:

E n g i n e e r i n g G e o l o g y

- Page 828:

E n g i n e e r i n g G e o l o g y

- Page 832:

E n g i n e e r i n g G e o l o g y

- Page 836:

E n g i n e e r i n g G e o l o g y

- Page 840:

E n g i n e e r i n g G e o l o g y

- Page 844:

412 Figure 8.15 (a) (b) (a) Rip-rap

- Page 848:

E n g i n e e r i n g G e o l o g y

- Page 852:

E n g i n e e r i n g G e o l o g y

- Page 856:

E n g i n e e r i n g G e o l o g y

- Page 860:

E n g i n e e r i n g G e o l o g y

- Page 864:

E n g i n e e r i n g G e o l o g y

- Page 868:

E n g i n e e r i n g G e o l o g y

- Page 872:

E n g i n e e r i n g G e o l o g y

- Page 876:

E n g i n e e r i n g G e o l o g y

- Page 880:

E n g i n e e r i n g G e o l o g y

- Page 884:

E n g i n e e r i n g G e o l o g y

- Page 888:

E n g i n e e r i n g G e o l o g y

- Page 892:

E n g i n e e r i n g G e o l o g y

- Page 896:

E n g i n e e r i n g G e o l o g y

- Page 900:

E n g i n e e r i n g G e o l o g y

- Page 904:

E n g i n e e r i n g G e o l o g y

- Page 908:

E n g i n e e r i n g G e o l o g y

- Page 912:

E n g i n e e r i n g G e o l o g y

- Page 916:

E n g i n e e r i n g G e o l o g y

- Page 920:

E n g i n e e r i n g G e o l o g y

- Page 924:

This page intentionally left blank

- Page 928:

E n g i n e e r i n g G e o l o g y

- Page 932:

E n g i n e e r i n g G e o l o g y

- Page 936:

E n g i n e e r i n g G e o l o g y

- Page 940:

E n g i n e e r i n g G e o l o g y

- Page 944:

E n g i n e e r i n g G e o l o g y

- Page 948:

E n g i n e e r i n g G e o l o g y

- Page 952:

E n g i n e e r i n g G e o l o g y

- Page 956:

E n g i n e e r i n g G e o l o g y

- Page 960:

E n g i n e e r i n g G e o l o g y

- Page 964:

E n g i n e e r i n g G e o l o g y

- Page 968:

E n g i n e e r i n g G e o l o g y

- Page 972:

E n g i n e e r i n g G e o l o g y

- Page 976:

E n g i n e e r i n g G e o l o g y

- Page 980:

E n g i n e e r i n g G e o l o g y

- Page 984:

E n g i n e e r i n g G e o l o g y

- Page 988:

E n g i n e e r i n g G e o l o g y

- Page 992:

E n g i n e e r i n g G e o l o g y

- Page 996:

488 Table 9.4. The rock mass rating

- Page 1000:

490 Table 9.6. Classification of in

- Page 1004:

492 Table 9.6. Classification of in

- Page 1008:

494 Table 9.6. Classification of in

- Page 1012:

E n g i n e e r i n g G e o l o g y

- Page 1016:

E n g i n e e r i n g G e o l o g y

- Page 1020:

E n g i n e e r i n g G e o l o g y

- Page 1024:

E n g i n e e r i n g G e o l o g y

- Page 1028:

E n g i n e e r i n g G e o l o g y

- Page 1032:

E n g i n e e r i n g G e o l o g y

- Page 1036:

E n g i n e e r i n g G e o l o g y

- Page 1040:

E n g i n e e r i n g G e o l o g y

- Page 1044:

E n g i n e e r i n g G e o l o g y

- Page 1048:

E n g i n e e r i n g G e o l o g y

- Page 1052:

E n g i n e e r i n g G e o l o g y

- Page 1056:

E n g i n e e r i n g G e o l o g y

- Page 1060:

E n g i n e e r i n g G e o l o g y

- Page 1064:

E n g i n e e r i n g G e o l o g y

- Page 1068:

E n g i n e e r i n g G e o l o g y

- Page 1072:

E n g i n e e r i n g G e o l o g y

- Page 1076:

E n g i n e e r i n g G e o l o g y

- Page 1080:

E n g i n e e r i n g G e o l o g y

- Page 1084:

532 Table 9.8. Typical compaction c

- Page 1088:

E n g i n e e r i n g G e o l o g y

- Page 1092:

E n g i n e e r i n g G e o l o g y

- Page 1096:

E n g i n e e r i n g G e o l o g y

- Page 1100:

E n g i n e e r i n g G e o l o g y

- Page 1104:

E n g i n e e r i n g G e o l o g y

- Page 1108:

E n g i n e e r i n g G e o l o g y

- Page 1112:

E n g i n e e r i n g G e o l o g y

- Page 1116:

E n g i n e e r i n g G e o l o g y

- Page 1120:

E n g i n e e r i n g G e o l o g y

- Page 1124:

E n g i n e e r i n g G e o l o g y

- Page 1128:

E n g i n e e r i n g G e o l o g y

- Page 1132:

E n g i n e e r i n g G e o l o g y

- Page 1136:

This page intentionally left blank

- Page 1140:

E n g i n e e r i n g G e o l o g y

- Page 1144:

E n g i n e e r i n g G e o l o g y

- Page 1148:

E n g i n e e r i n g G e o l o g y

- Page 1152:

E n g i n e e r i n g G e o l o g y

- Page 1156:

E n g i n e e r i n g G e o l o g y

- Page 1160:

E n g i n e e r i n g G e o l o g y

- Page 1164:

E n g i n e e r i n g G e o l o g y

- Page 1168:

E n g i n e e r i n g G e o l o g y

- Page 1172:

I n d e x coastal protection, 410,

- Page 1176:

I n d e x grout, 526, 548 groutabil

- Page 1180:

I n d e x rebound, 513 recumbent fo

- Page 1184:

This page intentionally left blank