Climate Action 2011-2012

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

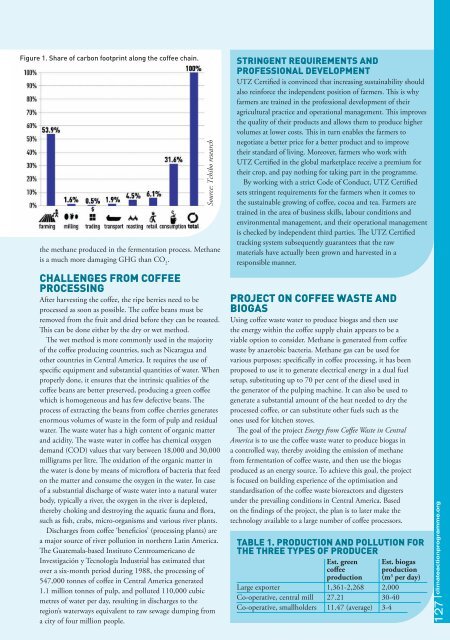

Figure 1. Share of carbon footprint along the coffee chain.<br />

Source: Tchibo research<br />

the methane produced in the fermentation process. Methane<br />

is a much more damaging GHG than CO 2<br />

.<br />

Challenges from Coffee<br />

proCessing<br />

After harvesting the coffee, the ripe berries need to be<br />

processed as soon as possible. The coffee beans must be<br />

removed from the fruit and dried before they can be roasted.<br />

This can be done either by the dry or wet method.<br />

The wet method is more commonly used in the majority<br />

of the coffee producing countries, such as Nicaragua and<br />

other countries in Central America. It requires the use of<br />

specific equipment and substantial quantities of water. When<br />

properly done, it ensures that the intrinsic qualities of the<br />

coffee beans are better preserved, producing a green coffee<br />

which is homogeneous and has few defective beans. The<br />

process of extracting the beans from coffee cherries generates<br />

enormous volumes of waste in the form of pulp and residual<br />

water. The waste water has a high content of organic matter<br />

and acidity. The waste water in coffee has chemical oxygen<br />

demand (COD) values that vary between 18,000 and 30,000<br />

milligrams per litre. The oxidation of the organic matter in<br />

the water is done by means of microflora of bacteria that feed<br />

on the matter and consume the oxygen in the water. In case<br />

of a substantial discharge of waste water into a natural water<br />

body, typically a river, the oxygen in the river is depleted,<br />

thereby choking and destroying the aquatic fauna and flora,<br />

such as fish, crabs, micro-organisms and various river plants.<br />

Discharges from coffee ‘beneficios’ (processing plants) are<br />

a major source of river pollution in northern Latin America.<br />

The Guatemala-based Instituto Centroamericano de<br />

Investigación y Tecnología Industrial has estimated that<br />

over a six-month period during 1988, the processing of<br />

547,000 tonnes of coffee in Central America generated<br />

1.1 million tonnes of pulp, and polluted 110,000 cubic<br />

metres of water per day, resulting in discharges to the<br />

region’s waterways equivalent to raw sewage dumping from<br />

a city of four million people.<br />

stringent requirements and<br />

professional development<br />

UTZ Certified is convinced that increasing sustainability should<br />

also reinforce the independent position of farmers. This is why<br />

farmers are trained in the professional development of their<br />

agricultural practice and operational management. This improves<br />

the quality of their products and allows them to produce higher<br />

volumes at lower costs. This in turn enables the farmers to<br />

negotiate a better price for a better product and to improve<br />

their standard of living. Moreover, farmers who work with<br />

UTZ Certified in the global marketplace receive a premium for<br />

their crop, and pay nothing for taking part in the programme.<br />

By working with a strict Code of Conduct, UTZ Certified<br />

sets stringent requirements for the farmers when it comes to<br />

the sustainable growing of coffee, cocoa and tea. Farmers are<br />

trained in the area of business skills, labour conditions and<br />

environmental management, and their operational management<br />

is checked by independent third parties. The UTZ Certified<br />

tracking system subsequently guarantees that the raw<br />

materials have actually been grown and harvested in a<br />

responsible manner.<br />

projeCt on Coffee waste and<br />

biogas<br />

Using coffee waste water to produce biogas and then use<br />

the energy within the coffee supply chain appears to be a<br />

viable option to consider. Methane is generated from coffee<br />

waste by anaerobic bacteria. Methane gas can be used for<br />

various purposes; specifically in coffee processing, it has been<br />

proposed to use it to generate electrical energy in a dual fuel<br />

setup, substituting up to 70 per cent of the diesel used in<br />

the generator of the pulping machine. It can also be used to<br />

generate a substantial amount of the heat needed to dry the<br />

processed coffee, or can substitute other fuels such as the<br />

ones used for kitchen stoves.<br />

The goal of the project Energy from Coffee Waste in Central<br />

America is to use the coffee waste water to produce biogas in<br />

a controlled way, thereby avoiding the emission of methane<br />

from fermentation of coffee waste, and then use the biogas<br />

produced as an energy source. To achieve this goal, the project<br />

is focused on building experience of the optimisation and<br />

standardisation of the coffee waste bioreactors and digesters<br />

under the prevailing conditions in Central America. Based<br />

on the findings of the project, the plan is to later make the<br />

technology available to a large number of coffee processors.<br />

table 1. produCtion and pollution for<br />

the three types of produCer<br />

Est. green Est. biogas<br />

coffee production<br />

production (m 3 per day)<br />

Large exporter 1,361-2,268 2,000<br />

Co-operative, central mill 27.21 30-40<br />

Co-operative, smallholders 11.47 (average) 3-4<br />

127 climateactionprogramme.org