Climate Action 2011-2012

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

operates so effectively that CO 2<br />

, nitrogen, carbon monoxide<br />

and carbon emissions are significantly lowered. At the same<br />

time, an innovative burner system and highly efficient<br />

heat exchangers ensure a greatly reduced gas consumption.<br />

However, the greatest energy saving for Volkswagen is from<br />

recycling the waste heat back into the process.<br />

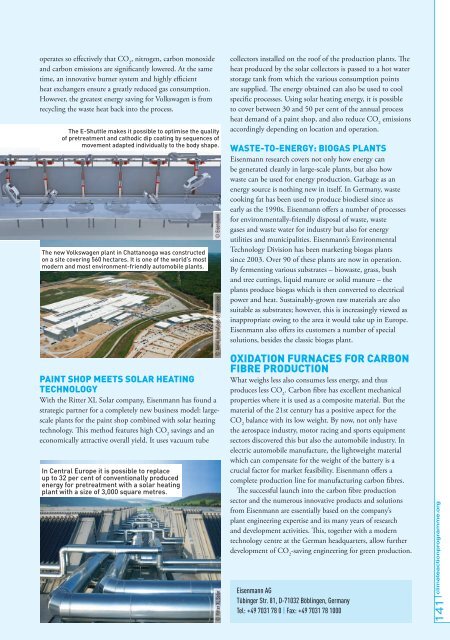

The E-Shuttle makes it possible to optimise the quality<br />

of pretreatment and cathodic dip coating by sequences of<br />

movement adapted individually to the body shape.<br />

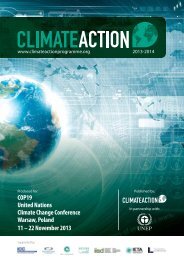

The new Volkswagen plant in Chattanooga was constructed<br />

on a site covering 560 hectares. It is one of the world’s most<br />

modern and most environment-friendly automobile plants.<br />

paint shop Meets solar heating<br />

technology<br />

With the Ritter XL Solar company, Eisenmann has found a<br />

strategic partner for a completely new business model: largescale<br />

plants for the paint shop combined with solar heating<br />

technology. This method features high CO 2<br />

savings and an<br />

economically attractive overall yield. It uses vacuum tube<br />

In Central Europe it is possible to replace<br />

up to 32 per cent of conventionally produced<br />

energy for pretreatment with a solar heating<br />

plant with a size of 3,000 square metres.<br />

© Ritter XL Solar © Aerial Innovations of Tennessee<br />

© Eisenmann<br />

collectors installed on the roof of the production plants. The<br />

heat produced by the solar collectors is passed to a hot water<br />

storage tank from which the various consumption points<br />

are supplied. The energy obtained can also be used to cool<br />

specific processes. Using solar heating energy, it is possible<br />

to cover between 30 and 50 per cent of the annual process<br />

heat demand of a paint shop, and also reduce CO 2<br />

emissions<br />

accordingly depending on location and operation.<br />

Waste-to-energy: biogas plants<br />

Eisenmann research covers not only how energy can<br />

be generated cleanly in large-scale plants, but also how<br />

waste can be used for energy production. Garbage as an<br />

energy source is nothing new in itself. In Germany, waste<br />

cooking fat has been used to produce biodiesel since as<br />

early as the 1990s. Eisenmann offers a number of processes<br />

for environmentally-friendly disposal of waste, waste<br />

gases and waste water for industry but also for energy<br />

utilities and municipalities. Eisenmann’s Environmental<br />

Technology Division has been marketing biogas plants<br />

since 2003. Over 90 of these plants are now in operation.<br />

By fermenting various substrates – biowaste, grass, bush<br />

and tree cuttings, liquid manure or solid manure – the<br />

plants produce biogas which is then converted to electrical<br />

power and heat. Sustainably-grown raw materials are also<br />

suitable as substrates; however, this is increasingly viewed as<br />

inappropriate owing to the area it would take up in Europe.<br />

Eisenmann also offers its customers a number of special<br />

solutions, besides the classic biogas plant.<br />

oxidation furnaces for carbon<br />

fibre production<br />

What weighs less also consumes less energy, and thus<br />

produces less CO 2<br />

. Carbon fibre has excellent mechanical<br />

properties where it is used as a composite material. But the<br />

material of the 21st century has a positive aspect for the<br />

CO 2<br />

balance with its low weight. By now, not only have<br />

the aerospace industry, motor racing and sports equipment<br />

sectors discovered this but also the automobile industry. In<br />

electric automobile manufacture, the lightweight material<br />

which can compensate for the weight of the battery is a<br />

crucial factor for market feasibility. Eisenmann offers a<br />

complete production line for manufacturing carbon fibres.<br />

The successful launch into the carbon fibre production<br />

sector and the numerous innovative products and solutions<br />

from Eisenmann are essentially based on the company’s<br />

plant engineering expertise and its many years of research<br />

and development activities. This, together with a modern<br />

technology centre at the German headquarters, allow further<br />

development of CO 2<br />

-saving engineering for green production.<br />

Eisenmann AG<br />

Tübinger Str. 81, D-71032 Böblingen, Germany<br />

Tel: +49 7031 78 0 | Fax: +49 7031 78 1000<br />

141 climateactionprogramme.org